Compound liquid laundry detergent and preparation method thereof

A laundry detergent and composite technology, applied in the field of daily chemicals, can solve problems such as multiple foams, and achieve the effect of simple preparation process, easy degradation, and good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

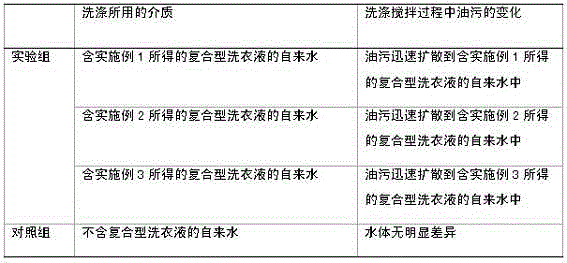

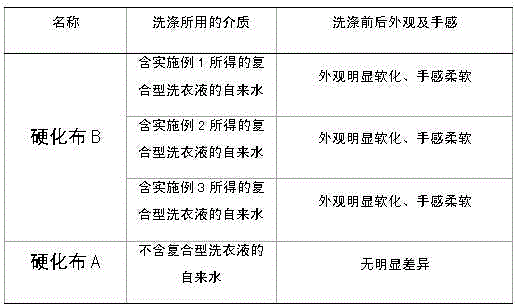

Examples

Embodiment 1

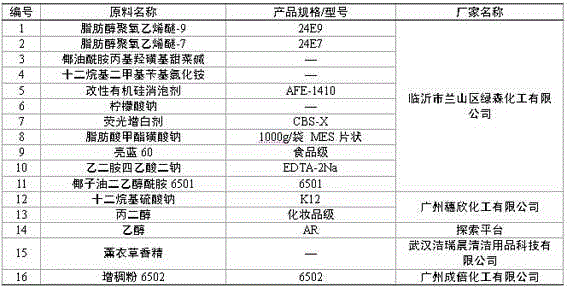

[0047] A kind of composite laundry detergent, calculated by mass percentage, its raw material composition and content are as follows:

[0048] Fatty alcohol polyoxyethylene ether-9 15%

[0049] Fatty alcohol polyoxyethylene ether-7 5%

[0050] Sodium fatty acid methyl ester sulfonate 4%

[0051] Sodium Lauryl Sulfate 4%

[0052] Cocamidopropyl Hydroxysultaine 6%

[0053] Lauryl Dimethyl Benzyl Ammonium Chloride 3%

[0054] Propylene Glycol 10%

[0055] Ethanol 2%

[0056] Modified silicone defoamer AFE-1410 0.25%

[0057]Auxiliary 2%

[0058] Fluorescent whitening agent CBS-X 0.03%

[0059] Fragrance 0.03%

[0060] Pigment 0.01%

[0061] Thickener 1%

[0062] The balance is deionized water;

[0063] Wherein said auxiliary agent is a mixture of disodium edetate and sodium citrate in a mass of 1:1;

[0064] Described essence is lavender essence;

[0065] The pigment is Brilliant Blue 60;

[0066] The thickener is coconut oil diethanolamide 6501.

[0067] The prep...

Embodiment 2

[0076] A kind of composite laundry detergent, calculated by mass percentage, its raw material composition and content are as follows:

[0077] Fatty alcohol polyoxyethylene ether-9 10%

[0078] Fatty alcohol polyoxyethylene ether-7 5%

[0079] Sodium fatty acid methyl ester sulfonate 4%

[0080] Sodium Lauryl Sulfate 4%

[0081] Cocamidopropyl Hydroxysultaine 6%

[0082] Lauryl Dimethyl Benzyl Ammonium Chloride 3%

[0083] Propylene Glycol 10%

[0084] Ethanol 2%

[0085] Modified silicone defoamer AFE-1410 0.25%

[0086] Auxiliary 2%

[0087] Fluorescent whitening agent CBS-X 0.03%

[0088] Fragrance 0.03%

[0089] Pigment 0.01%

[0090] Thickener 1.5%

[0091] The balance is deionized water;

[0092] Wherein, the disodium edetate and sodium citrate are calculated by mass ratio, that is, the amount of disodium edetate: sodium citrate is a mixture composed of 3:1;

[0093] Described essence is lavender essence;

[0094] The pigment is Brilliant Blue 60;

[0095]...

Embodiment 3

[0105] A kind of composite laundry detergent, calculated by mass percentage, its raw material composition and content are as follows:

[0106] Fatty alcohol polyoxyethylene ether-9 10%

[0107] Fatty alcohol polyoxyethylene ether-7 5%

[0108] Sodium fatty acid methyl ester sulfonate 6%

[0109] Sodium Lauryl Sulfate 6%

[0110] Cocamidopropyl Hydroxysultaine 6%

[0111] Lauryl Dimethyl Benzyl Ammonium Chloride 3%

[0112] Propylene Glycol 10%

[0113] Ethanol 2%

[0114] Modified silicone defoamer AFE-1410 0.25%

[0115] Auxiliary 2%

[0116] Fluorescent whitening agent CBS-X 0.03%

[0117] Fragrance 0.03%

[0118] Pigment 0.01%

[0119] Thickener 2%

[0120] The balance is deionized water;

[0121] Wherein the auxiliary agent is disodium edetate and sodium citrate, calculated by mass ratio, that is, the amount of disodium edetate: sodium citrate is a mixture composed of 3:1;

[0122] Described essence is lavender essence;

[0123] The pigment is Brilliant Blue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com