Water-soluble non-phosphorus degreasing agent for permanent magnet material

A phosphorus-free degreaser and permanent magnet material technology, applied in the field of water-soluble phosphate-free degreaser and permanent magnet material degreasing, can solve problems such as environmental pollution, achieve large oil pollution load, excellent washing performance, prevent The effect of resorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

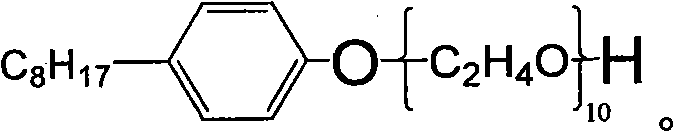

Method used

Image

Examples

Embodiment 1

[0028] Weigh 5 grams of sodium hydroxide, 15 grams of sodium carbonate, 5 grams of DEA, and 5 grams of Triton, respectively, and dissolve them in 1 liter of water with a pH of 7.5 and a temperature of 80°C. Divide the sintered NdFeB permanent magnet material sample into three parts and put it into it for degreasing for 1 minute, 5 minutes and 24 hours.

Embodiment 2

[0030] Weigh 5 grams of sodium hydroxide, 15 grams of sodium carbonate, 20 grams of sodium gluconate, 15 grams of PAA, and 3 grams of Triton, and dissolve them in 1 liter of water with a pH of 8.0 and a temperature of 60°C. Divide the sample of bonded NdFeB permanent magnet material into three parts and put it into it for degreasing for 1 minute, 5 minutes and 24 hours.

Embodiment 3

[0032] Weigh 10 grams of sodium hydroxide, 15 grams of sodium carbonate, 5 grams of sodium gluconate, 10 grams of PAA, and 4 grams of Triton, and dissolve them in 1 liter of water with a pH of 8.0 and a temperature of 60°C. Divide the sintered NdFeB permanent magnet material sample into three parts and put it into it for degreasing for 1 minute, 5 minutes and 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com