Oil removal powder for metal surface and preparation method thereof

A metal surface and surfactant technology, applied in the field of detergents, can solve the problems of easy precipitation of surfactants, poor oil removal ability, large foam, etc., and achieve the effects of wide application range, strong oil removal ability and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

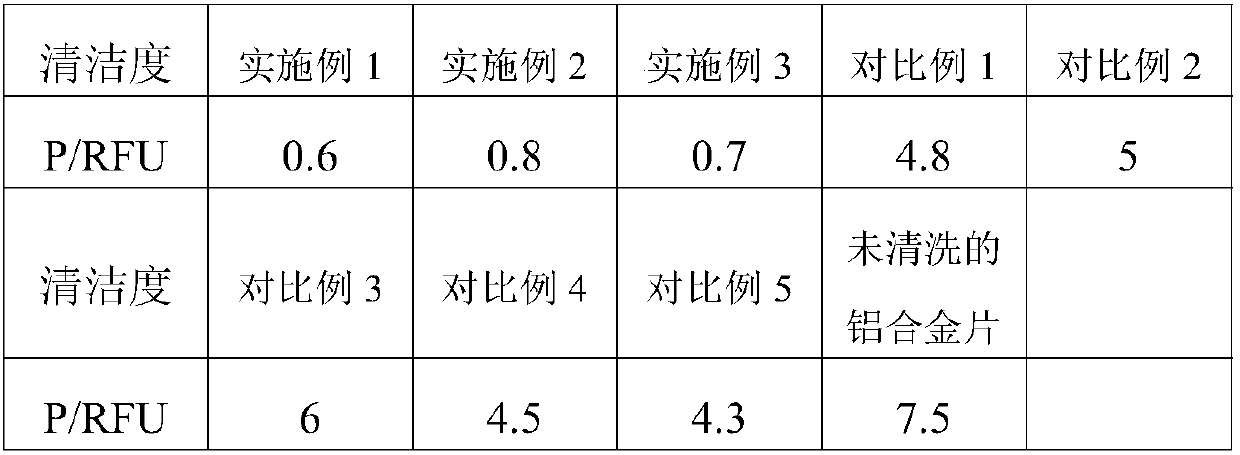

Examples

Embodiment 1

[0043] This embodiment provides a kind of degreasing powder, and the preparation method comprises the following steps:

[0044] (1) Mix 20 grams of sodium carbonate, 5 grams of borax and 0.5 grams of disodium EDTA, and stir to obtain A powder;

[0045] (2) Mix 8 grams of sodium citrate and 40 grams of sodium metasilicate pentahydrate, and stir to obtain B powder;

[0046] (3) Mix A powder and B powder, add 1 gram of nonylphenol polyoxyethylene ether, 1 gram of fatty acid methyl ester ethoxylate, 0.5 gram of fatty alcohol polyoxyethylene ether sodium sulfate, and stir well to obtain the finished product. oil powder.

Embodiment 2

[0048] This embodiment provides a kind of degreasing powder, and the preparation method comprises the following steps:

[0049] (1) Mix 30 grams of sodium carbonate, 10 grams of borax and 1 gram of disodium EDTA, and stir to obtain A powder;

[0050] (2) Mix 10 grams of sodium citrate and 50 grams of sodium metasilicate pentahydrate, and stir to obtain B powder;

[0051] (3) Mix A powder and B powder, add 2.5 grams of nonylphenol polyoxyethylene ether, 3 grams of fatty acid methyl ester ethoxylate, 2 grams of fatty alcohol polyoxyethylene ether sodium sulfate, and stir well to get the finished product. oil powder.

Embodiment 3

[0053] This embodiment provides a kind of degreasing powder, and the preparation method comprises the following steps:

[0054] (1) Mix 25 grams of sodium carbonate, 7 grams of borax and 0.7 grams of disodium EDTA, and stir to obtain A powder;

[0055] (2) Mix 9 grams of sodium citrate and 45 grams of sodium metasilicate pentahydrate, and stir to obtain powder B;

[0056] (3) Mix A powder and B powder, add 2 grams of nonylphenol polyoxyethylene ether, 2 grams of fatty acid methyl ester ethoxylate, 1 gram of fatty alcohol polyoxyethylene ether sodium sulfate, and stir well to get the finished product. oil powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com