Preparation method of hybrid porous polymer based on cage and ladder type structure silsesquioxane

A technology of silsesquioxane and porous polymers, which is applied in the field of preparation of hybrid porous polymers, can solve problems such as insufficient research on porous materials, and achieve easy control of preparation process conditions, high specific surface area, and good chemical stability and thermal stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

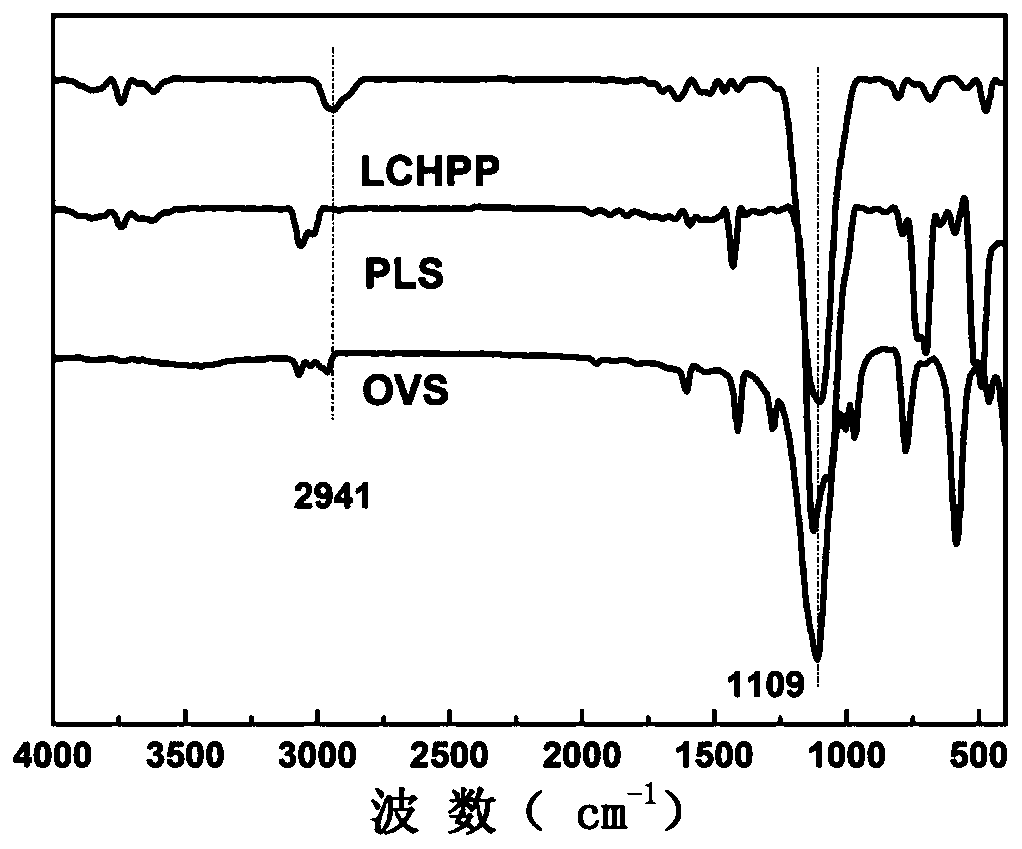

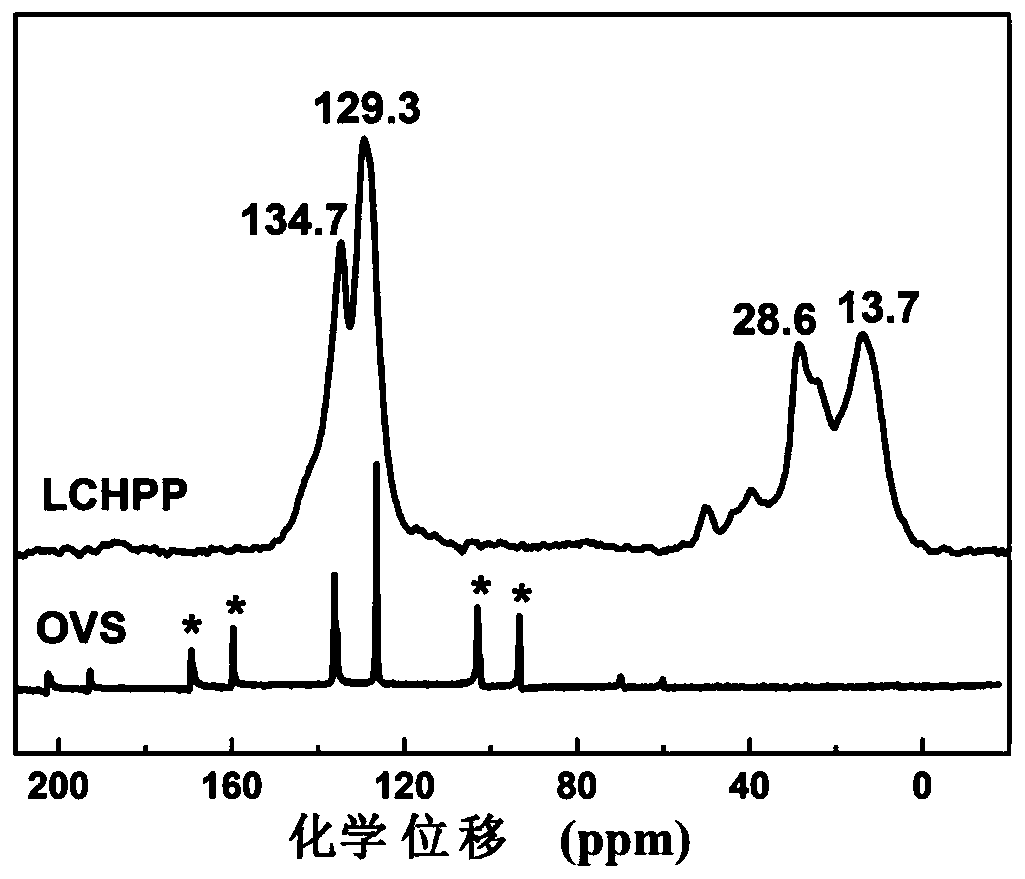

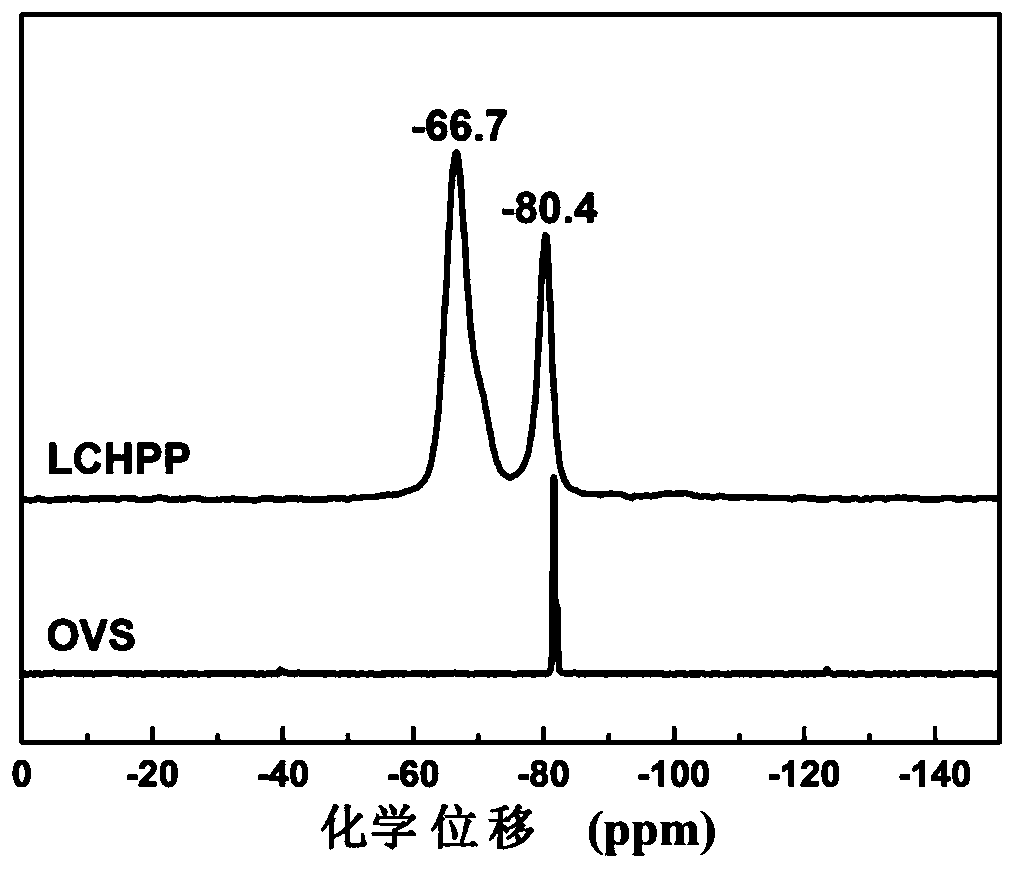

[0047] A kind of preparation method based on the hybrid porous polymer (LCHPP) of cage type and ladder structure silsesquioxane, comprises steps:

[0048] (1) Add 0.632g of octavinylsilsesquioxane (OVS) with a cage structure, 0.291g of dodecylphenyl substituted tricyclic Ladder silsesquioxane (PLS), 25mL 1,2-dichloroethane, stirred for 15 minutes, added 0.200g of anhydrous aluminum trichloride, stirred at room temperature for 30 minutes, then heated to 85°C, reacted for 24h; After the reaction was completed, the reaction system was naturally cooled to room temperature, suction filtered, and the obtained solid was washed with methanol, tetrahydrofuran, chloroform, and acetone for 3 times respectively to obtain solid I;

[0049] (2) Soxhlet extract the obtained solid I with methanol and dichloromethane for 24 hours respectively, and vacuum-dry the obtained solid at 80° C. for 24 hours to obtain LCHPP.

[0050] The specific surface area of the product obtained in this embodime...

Embodiment 2

[0059] A kind of preparation method based on the hybrid porous polymer (LCHPP) of cage type and ladder structure silsesquioxane, comprises steps:

[0060] (1) Add 0.632g of octavinylsilsesquioxane (OVS) with a cage structure, 0.437g of dodecylphenyl substituted tricyclic Ladder silsesquioxane (PLS), 25ml 1,2-dichloroethane, stirred for 15 minutes, added 0.200g of anhydrous aluminum trichloride, stirred at room temperature for 30 minutes, then heated to 85°C, reacted for 24h; After the reaction was completed, the reaction system was naturally cooled to room temperature, suction filtered, and the obtained solid was washed with methanol, tetrahydrofuran, chloroform, and acetone for 3 times respectively to obtain solid I;

[0061] (2) Soxhlet extract the obtained solid I with methanol and dichloromethane for 24 hours respectively, and vacuum-dry the obtained solid at 80° C. for 24 hours to obtain LCHPP.

[0062] The specific surface area of the product obtained in this embodime...

Embodiment 3

[0064] A kind of preparation method based on the hybrid porous polymer (LCHPP) of cage type and ladder structure silsesquioxane, comprises steps:

[0065] (1) Add 0.632g of octavinylsilsesquioxane (OVS) with a cage structure, 0.218g of dodecylphenyl substituted tricyclic Ladder silsesquioxane (PLS), 25mL 1,2-dichloroethane, stirred for 15 minutes, added 0.200g of anhydrous aluminum trichloride, stirred at room temperature for 30 minutes, then heated to 85°C, reacted for 24h; After the reaction was completed, the reaction system was naturally cooled to room temperature, suction filtered, and the obtained solid was washed with methanol, tetrahydrofuran, chloroform, and acetone for 3 times respectively to obtain solid I;

[0066] (2) Soxhlet extract the obtained solid I with methanol and dichloromethane for 24 hours respectively, and vacuum-dry the obtained solid at 80° C. for 24 hours to obtain LCHPP.

[0067] The specific surface area of the product obtained in this embodime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com