Railway turnout repair device and rail burr repair method

A technology for turnouts and railways, which is applied in the field of railway turnout repair devices, can solve the problems that the grinding effect depends on the operator, the effect varies from person to person, and the grinding speed is slow, and achieves the effects of convenient handling equipment, low production cost and labor saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

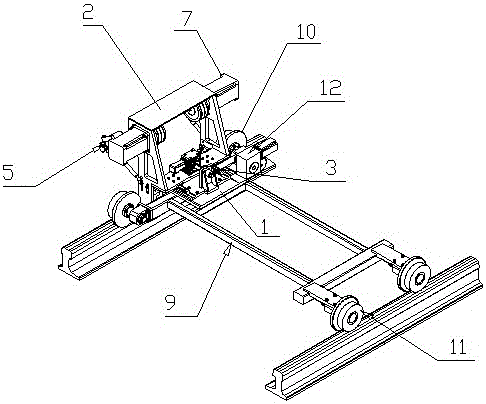

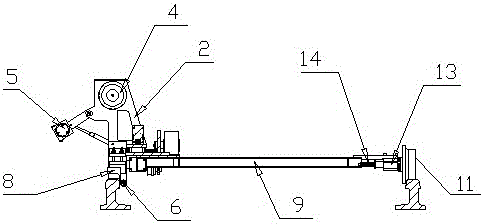

[0022] Such as figure 1 A railway turnout repairing device is shown, which includes a grinding mechanism and a traveling frame. The traveling frame is mounted above the double rails and can walk along the track. The grinding mechanism is arranged above the track to be polished on one side of the traveling frame. The grinding mechanism includes Base 1, adjustable frame 2, abrasive belt driving mechanism, base 1 is fixedly connected with the traveling frame, adjustable frame 2 is movably connected with base 1 by adjusting the driving mechanism 3, and the abrasive belt driving mechanism is set on the adjustable frame 2 Above; the abrasive belt driving mechanism includes a driving wheel 4, a tensioning wheel 5, and a bottom wheel 6, and the abrasive belt sequentially touches and bypasses the driving wheel 4, the tensioning wheel 5, and the bottom wheel 6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com