Synchronously-constructed asphalt base cloth sealing layer

An asphalt-based and asphalt-based technology, which is applied in the field of synchronous asphalt-based cloth seals, can solve the problems of poor waterproofness and anti-reflection of gravel seals, and achieve the effects of ensuring integrity and continuity, good durability, and preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

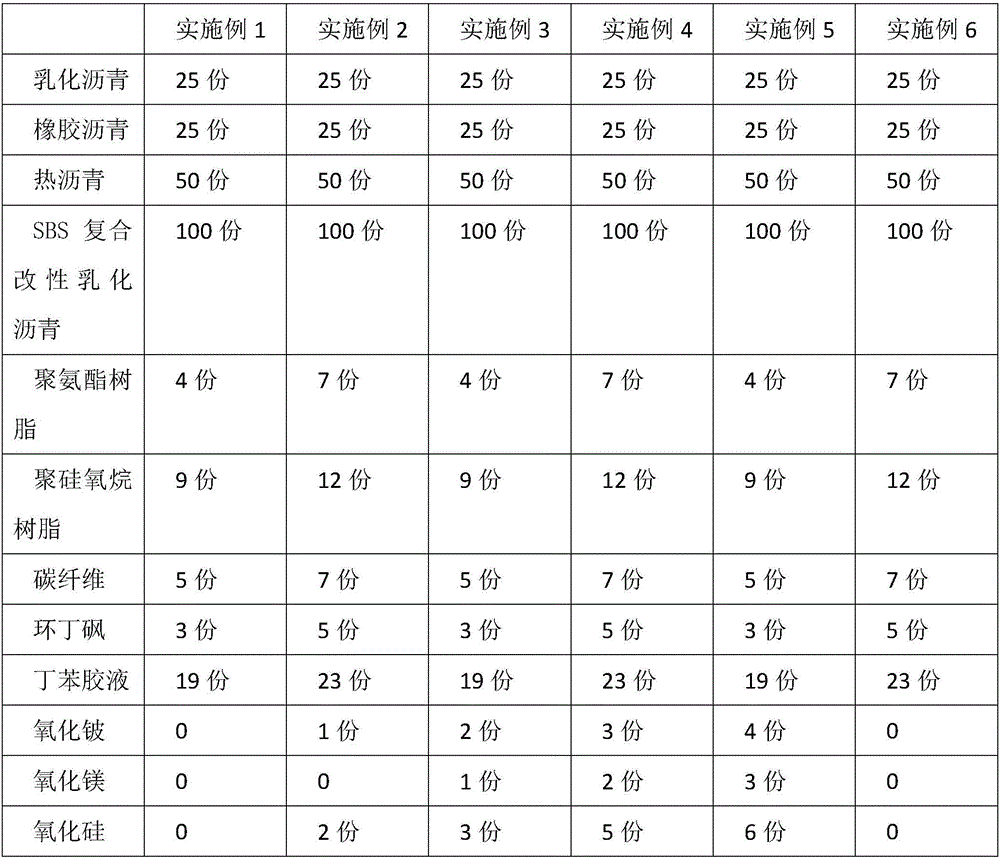

[0022] The present invention will be described in further detail below by means of specific embodiments:

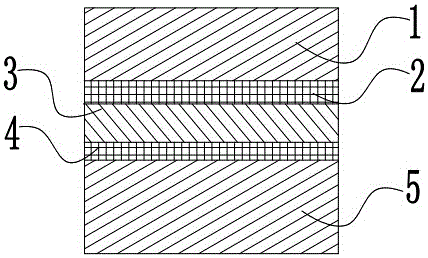

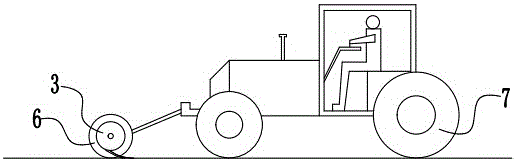

[0023] The reference signs in the accompanying drawings of the specification include: surface layer 1, second adhesive layer 2, polypropylene cloth 3, first adhesive layer 4, base layer 5, front driven wheel 6, single-row rubber wheel 7.

[0024] The embodiment is basically as shown in the accompanying drawings: the synchronous asphalt-based cloth sealing layer in this scheme includes the second adhesive layer 2, the polypropylene cloth 3 and the first adhesive layer 4 that are sequentially stacked and connected from top to bottom, wherein the first adhesive layer One adhesive layer 4 is connected with the pavement base layer 5 , and the second adhesive layer 2 is connected with the pavement surface layer 1 . The pavement surface layer 1 here can be a cement pavement, an asphalt pavement, a gravel layer, etc., and the pavement base 5 can be a rigid base (cement concrete),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com