Cantilever assembly construction technology for long span continuous steel truss girder flexible arch bridge

A construction technology and technology of steel truss girders, which are applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of difficult alignment, high safety risk, and long construction period, etc., so as to reduce construction difficulty and suffer The effect of clear force and more work surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

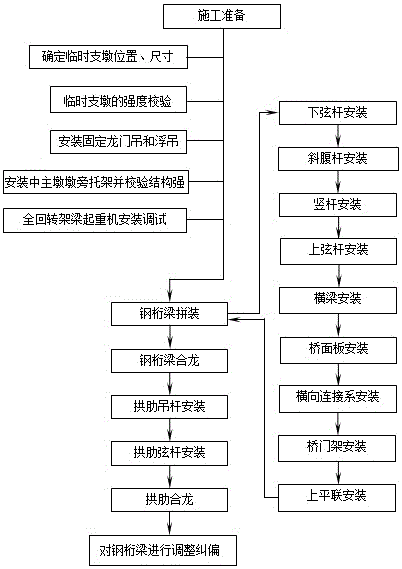

[0043] combined with figure 1 As shown, a long-span continuous steel truss girder flexible arch bridge cantilever assembly construction technology includes the following steps:

[0044] (1) Install temporary buttresses and brackets next to the middle main pier in sequence;

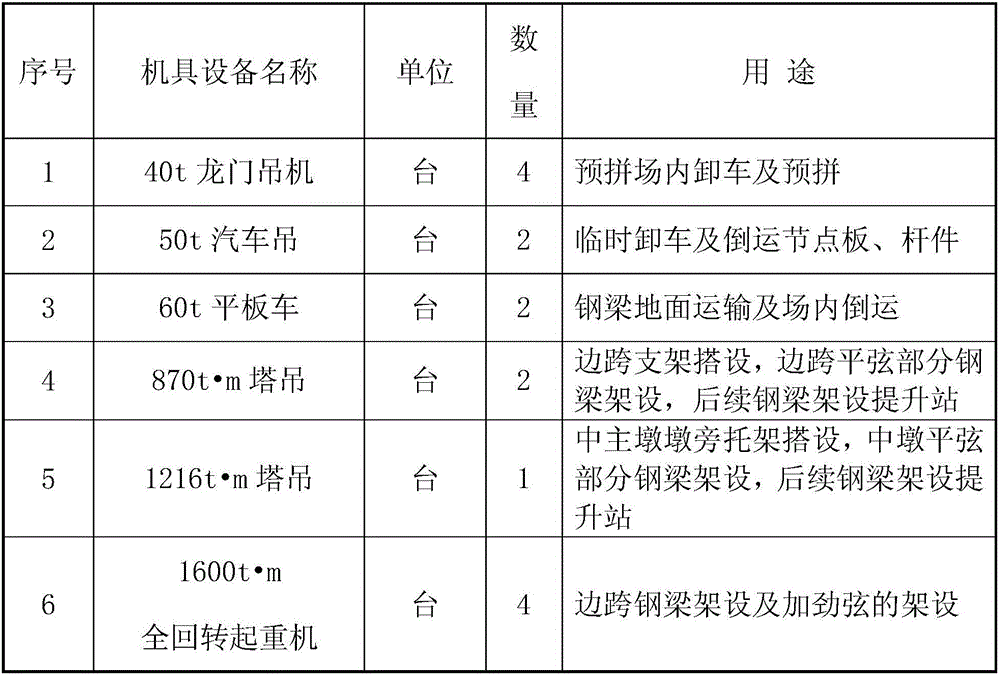

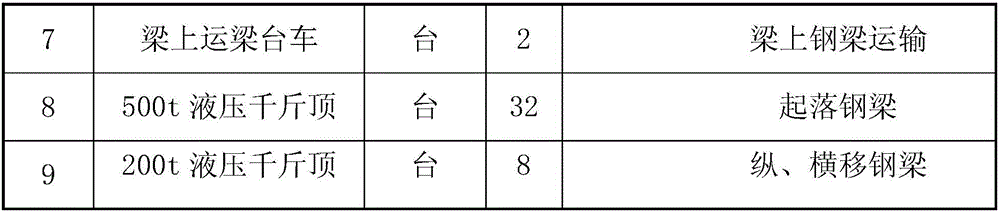

[0045] (2) Install a full-slewing crane on the bracket next to the installed middle main pier;

[0046] (3) Assembly of steel truss beams;

[0047] (4) Closure of steel truss beams;

[0048] (5) Install arch ribs and arch rib chords in sequence;

[0049] (6) Adjust and correct the deviation of the steel truss girder.

[0050] In the present embodiment, the step (1) includes the following steps:

[0051] 1.1 Determine the installation location and structural size of the temporary pier: the temporary pier is respectively installed in the middle of the side spans on both sides and in the middle of each mid-span; the structure of the temporary pier is mainly composed of four sets of steel pipe piles, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com