Concrete steel formwork support construction method

A construction method and formwork support technology, which is applied in the fields of formwork/formwork/work frame, treatment of formwork, preparation of building components on site, etc., can solve problems such as large space and large height, and achieve simple and safe construction technology Effect with high coefficient and easy to grasp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

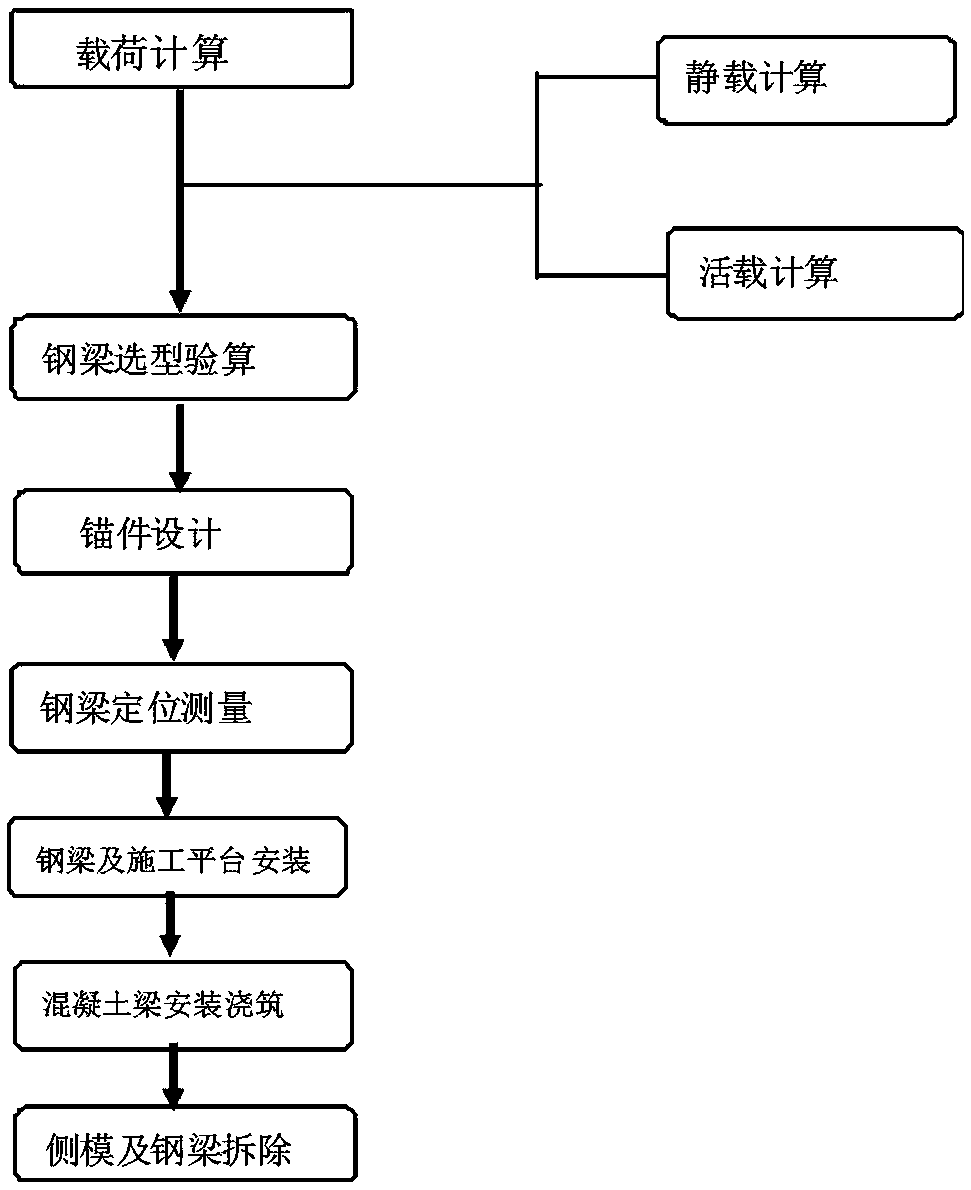

[0044] Below in conjunction with accompanying drawing, the concrete steel formwork support construction method of the present invention is described in detail below.

[0045] As shown in the accompanying drawings, the concrete steel formwork support construction method of the present invention, the steps of the construction method include:

[0046] A. Load calculation

[0047] 1. The relevant parameters are selected according to the specific gravity of concrete 24 KN / m3, the specific gravity of steel bar 1.5KN / m3, the template 0.15KN / m2, the support 0.1KN / m2, and the vibration load 2 KN / m3

[0048] 2. Concrete load N1=57.6 KN, steel load N2=3.6 KN, support load N3=4.8KN, vibration load N4=4.8KN

[0049] 3. Single-layer combined load, the load factor is 1.2, N=(57.6 KN+3.6 KN+4.8 KN+4.8)×1.2KN =84.96KN

[0050] 4. The load acting on the simply supported steel beam is calculated according to the uniform load, and the uniform load q is calculated (four steel beams are preset to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com