Hydrostatic linear actuator and device with hydrostatic linear actuator

A linear actuator and hydrostatic technology, applied in the direction of fluid pressure actuators, oil supply tank devices, engines, etc., to achieve the effect of minimizing the structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

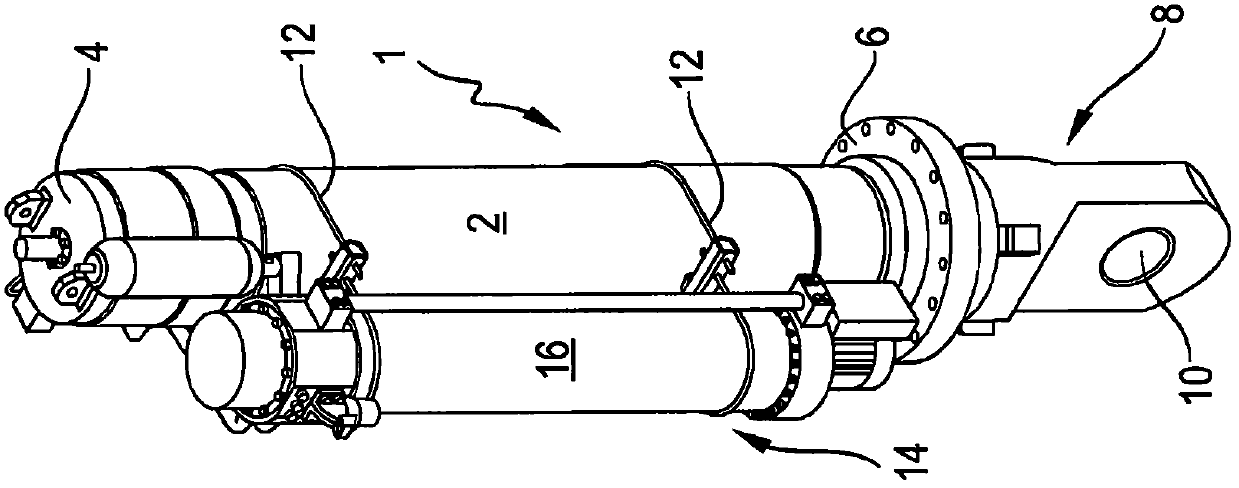

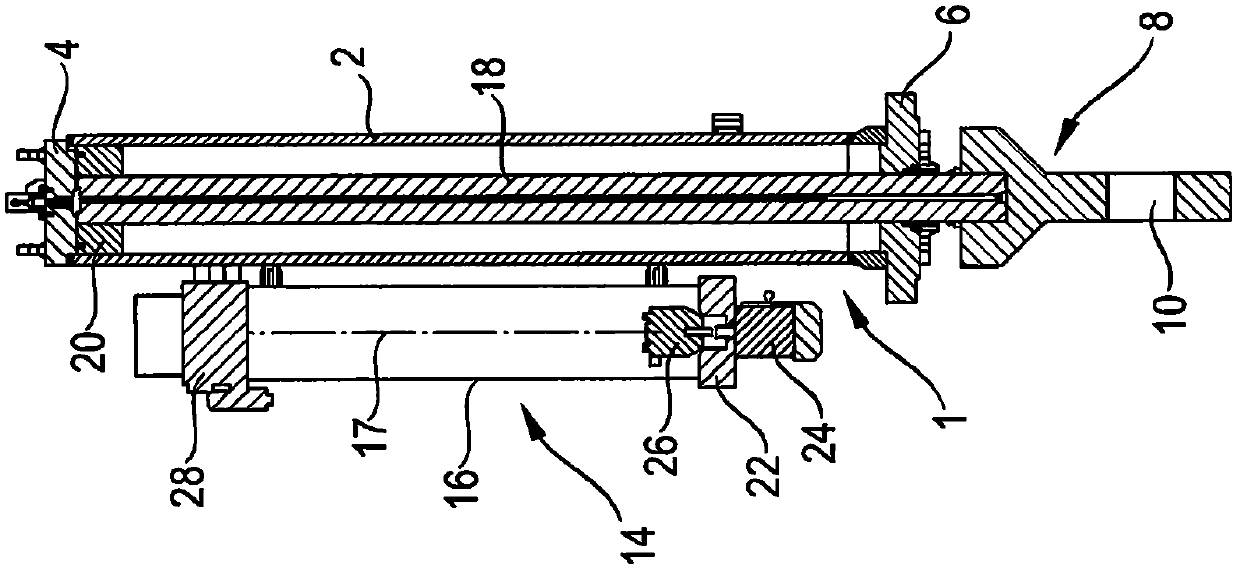

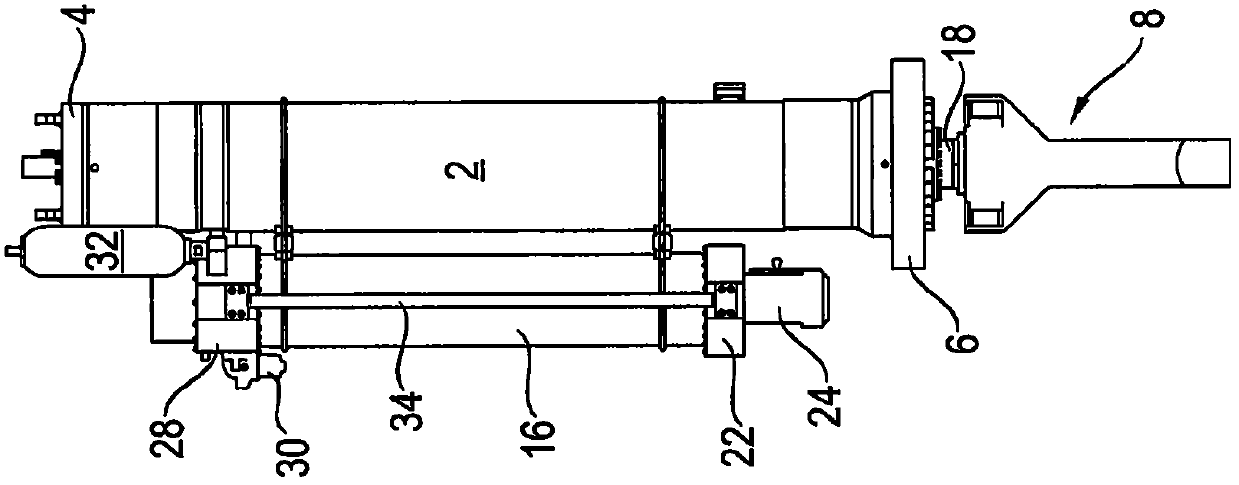

[0035] figure 1 An embodiment of an actuator according to the invention is shown. The actuator has a differential cylinder 1 in which the figure 1 A cylindrical cylinder tube 2 with a bottom-side closing plate 4 and a rod-side closing plate 6 is shown in FIG. The closure plate 6 on the piston rod side is closed (in figure 1 Not shown in ) the piston rod passes through, and the coupling element 8 with the eye 10 is fastened on its free end section.

[0036]The low-pressure accumulator 14 is fastened parallel to the cylinder tube 2 by means of two spaced apart, angled fastening means 12 , wherein the two fastening means 12 each enclose the cylinder tube of the differential cylinder 1 2 and the cylindrical pipe fitting 16 of the low pressure accumulator 14.

[0037] figure 2 A sectional view of this embodiment of the actuator according to the invention is shown. A piston rod 18 is shown inside the cylinder tube 2 , which rigidly connects the piston 20 of the differential c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com