Absolute type azimuth photoelectric encoder

A technology of photoelectric encoder and azimuth angle, which is applied in the direction of instruments, conversion sensor output, measuring devices, etc., can solve the problems of poor impact resistance, large error and even code error of metal code disc, so as to reduce production difficulty and increase rigidity Strength, the effect of simplifying the mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

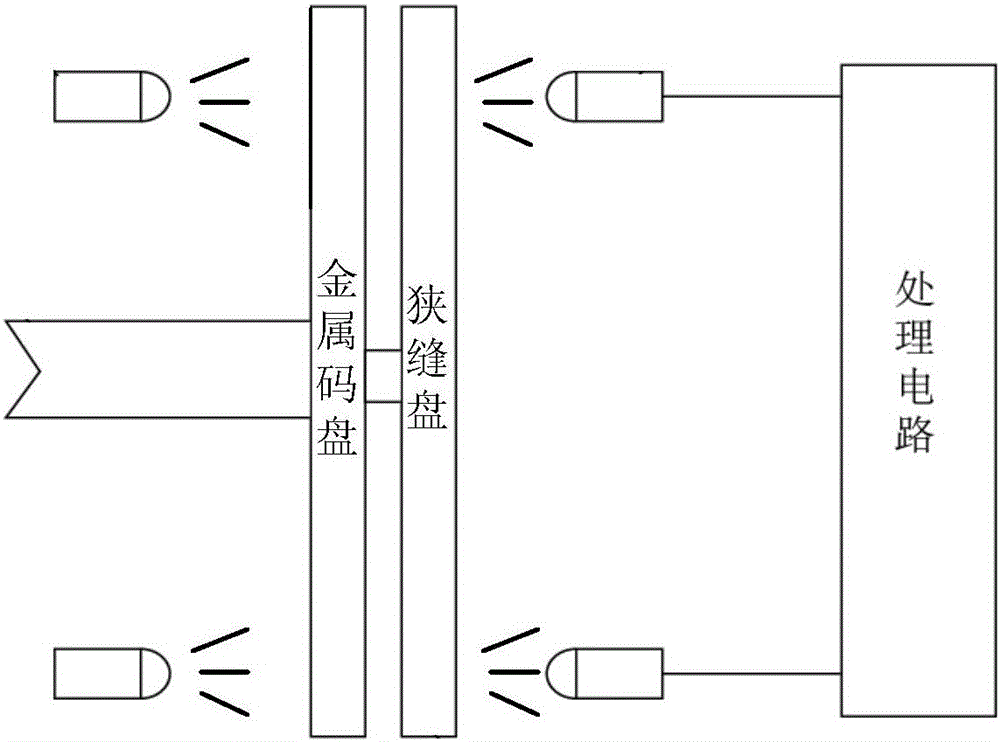

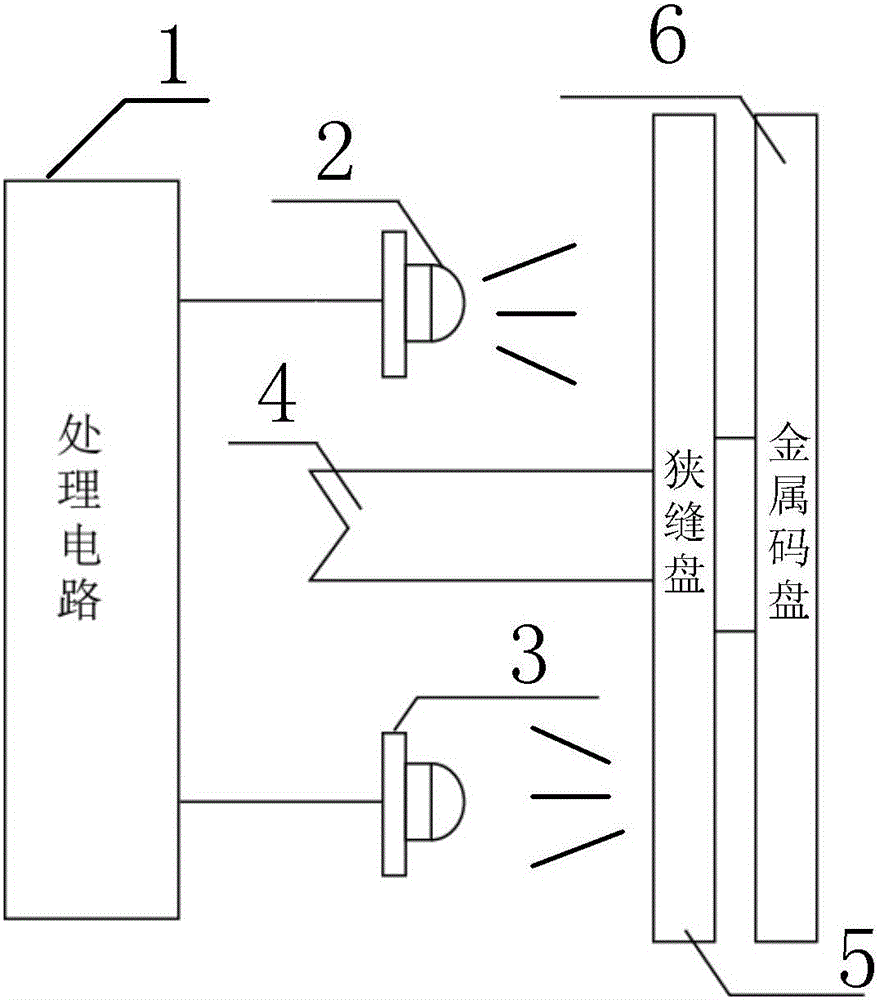

[0056] Specific implementation mode one: see figure 2 Describe this embodiment. An absolute azimuth photoelectric encoder described in this embodiment includes a processing circuit 1, a light emitting tube 2, a photodiode 3, a main shaft 4, and an absolute encoder disc. The feature is that the absolute encoder disc includes a narrow The slit disc 5 and the metal code disc 6, and the slit disc 5 and the metal code disc 6 have the same size, and the code word area of the metal code disc 6 is in the form of a depression or blackening,

[0057] The slit disc 5 and the metal code disc 6 are installed in parallel on the main shaft 4, there is an axial working gap between the slit disc 5 and the metal code disc 6, the metal code disc 6 follows the rotation of the main shaft 4, and the slit disc 5 remains stationary.

[0058] The processing circuit 1 is used to provide electric energy to the luminous tube 2, and the light emitted by the luminous tube 2 passes through the slit on th...

specific Embodiment approach 2

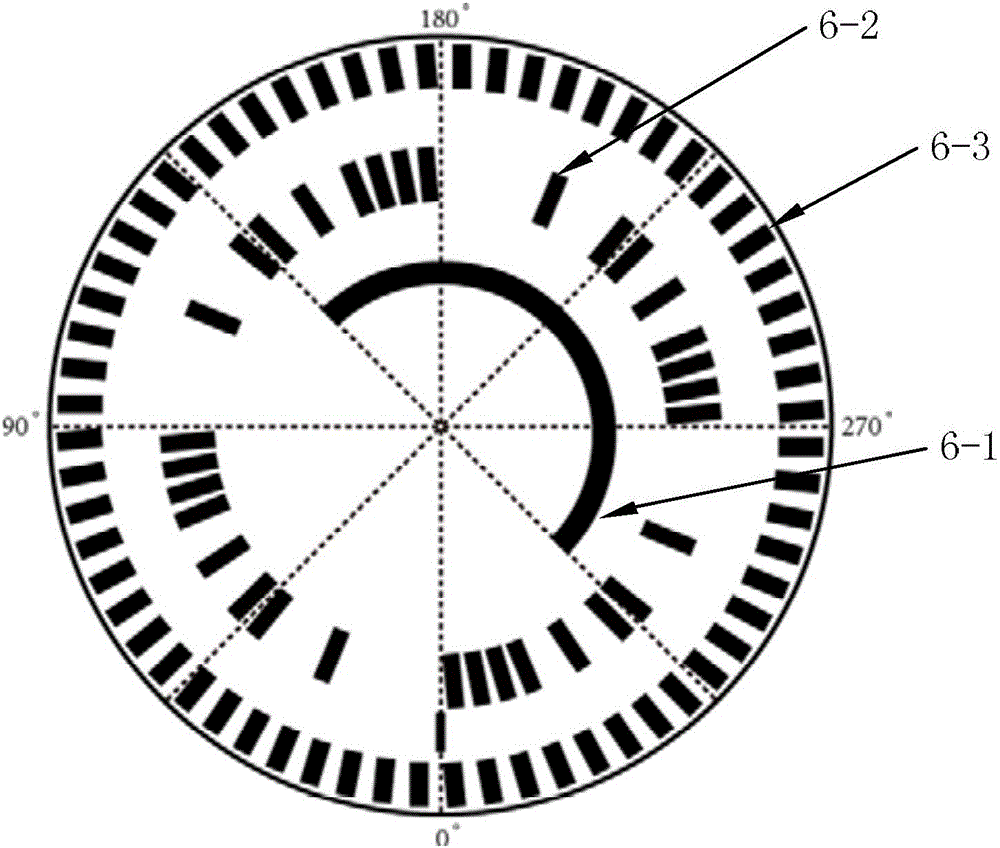

[0063] Specific implementation mode two: see image 3 and 4 Describe this embodiment. The difference between this embodiment and the azimuth photoelectric encoder described in the first embodiment is that the metal code disc 6 is an azimuth code disc, and the slit disc 5 is an azimuth slit. sewing plate;

[0064] On the azimuth code disc, there are three circles of code tracks from the inside to the outside, which are successively the first circle of metal code tracks 6-1, the second circle of metal code tracks 6-2 and the third circle of metal code tracks 6-3, and Set the metal code wheel 6 to take the geographic south direction as 0°, and the angle θ gradually increases to 360° in the clockwise direction,

[0065] The first round of metal track 6-1:

[0066] In the areas of 0°<θ<135° and 315°<θ≤360°, all are areas without codewords;

[0067] In the area of 135°≤θ≤315°, all are areas with codewords;

[0068] The second round of metal track 6-2:

[0069] In the area of...

specific Embodiment approach 3

[0082] Specific implementation mode three: see image 3 and 4 Describe this embodiment, the difference between this embodiment and the azimuth photoelectric encoder described in the second embodiment is that the metal code track 6-2 in the second circle and the metal code track 6 in the third circle The 0° position between -3 is provided with a check code bit, and the check code bit is an area with a code word, and the check code bit is used for checking and correcting the initial position of the metal code disc 6 .

[0083] In this embodiment, a check code bit is provided at the 0° position between the second circle of metal code track 6-2 and the third circle of metal code track 6-3, and the check code bit is a code word area, the verification code bit is used as the inspection and correction of the initial position of the metal code disc 6, and under the joint action of the three-circle code track, the azimuth encoder can read the angle code word result that meets the accu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com