Application of zinc sulfide in mechanoluminescent sensor, mechanoluminescent sensor, preparation method of mechanoluminescent sensor and application of zinc sulfide and mechanoluminescent sensor

A zinc sulfide and sensor technology, which is applied in the measurement of the change of optical properties of materials when they are stressed, the testing of machine/structural components, instruments, etc., can solve problems such as complex optical equipment, and achieve a wide range of applications, The effect of great application value and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] In a third aspect, the present invention also provides a method for preparing a visual sensor based on mechanoluminescence as described above, the method comprising: coating the suspension of zinc sulfide particles doped with a transition metal element as described above on the above-mentioned on the basis described above.

[0032] The inventors of the present invention have found that although the above-mentioned transition metal element-doped zinc sulfide particle suspension is prepared into a suspension in a solvent, and then coated on the substrate, a sensor meeting the requirements of the present invention can be prepared, However, when the suspension also contains polymer substances, the sensitivity and accuracy of the final sensor will be further improved.

[0033] According to the present invention, the content of the transition metal element-doped zinc sulfide particles can also vary within a wide range, preferably, based on 100 parts by weight of the suspension,...

Embodiment 1

[0043] This example is used to illustrate the preparation method of the mechanoluminescence-based visual sensor of the present invention

[0044] (1) Preparation of zinc sulfide particles doped with transition metal elements

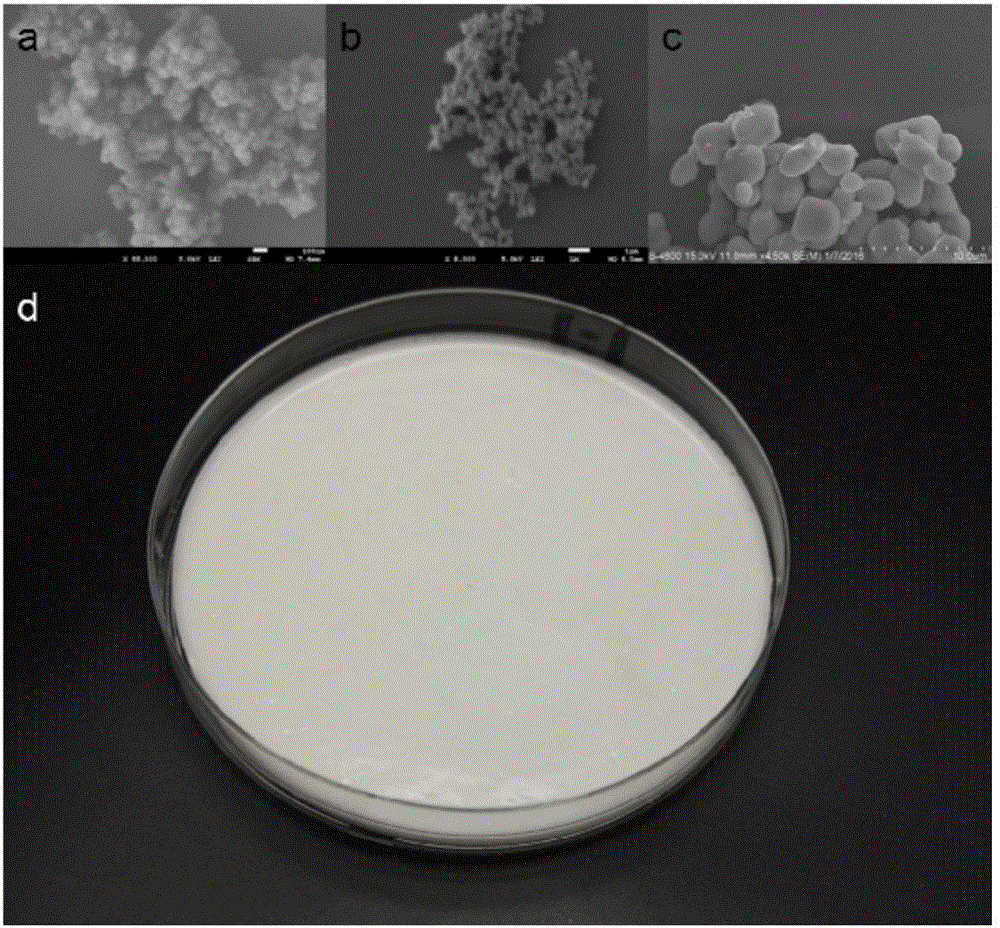

[0045] Mix manganese and zinc sulfide powders at a molar ratio of 1:100, place them in a tube furnace (commercially available from Xi'an Tianhong Instrument Co., Ltd. with the brand name GSK14-2), and heat to 1050°C after vacuuming. 30 minutes after the start of heating, the temperature reached 1050° C., continued heating at this temperature for 3 hours, then stopped heating and cooled naturally to obtain manganese-doped zinc sulfide (ZnS: Mn) particles. The scanning electron microscope (Hitachi JSM-7500F ) pictures and physical pictures see figure 1 as shown in a. Wherein, the particle diameter of described particle is 20nm; By changing the feeding powder size of different zinc sulfide and manganese, also can obtain 200nm, the particle diameter of 2 μ...

Embodiment 2

[0049] This example is used to illustrate the preparation method of the mechanoluminescence-based visual sensor of the present invention

[0050] (1) Preparation of zinc sulfide particles doped with transition metal elements

[0051] Mix copper and zinc sulfide powder according to the molar ratio of 1:120, place in a tube furnace, and heat to 1000°C after vacuuming. 20 minutes after the start of heating, the temperature reached 1000° C., continued heating at this temperature for 4 hours, then stopped heating, and cooled naturally to obtain copper-doped zinc sulfide (ZnS:Cu) particles, wherein the particle size of the particles was 15 nm .

[0052] (2) Fabrication of a visual sensor based on mechanoluminescence

[0053] Stir and disperse the ZnS:Cu particles and starch obtained in step (1) in methanol to obtain a suspension containing 1.5% by weight of ZnS:Cu particles, 3% by weight of starch and methanol as the balance. The suspension is magnetically stirred (the magnetic s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com