Method for measuring microscopic mechanical property parameter of press-fitting material

A micromechanics and performance technology, applied in the direction of testing material hardness, etc., can solve the problems of inability to accurately know the micromechanical properties of indented convex materials, inability to quickly and effectively calculate the indenter, etc., to achieve the effect of low cost and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

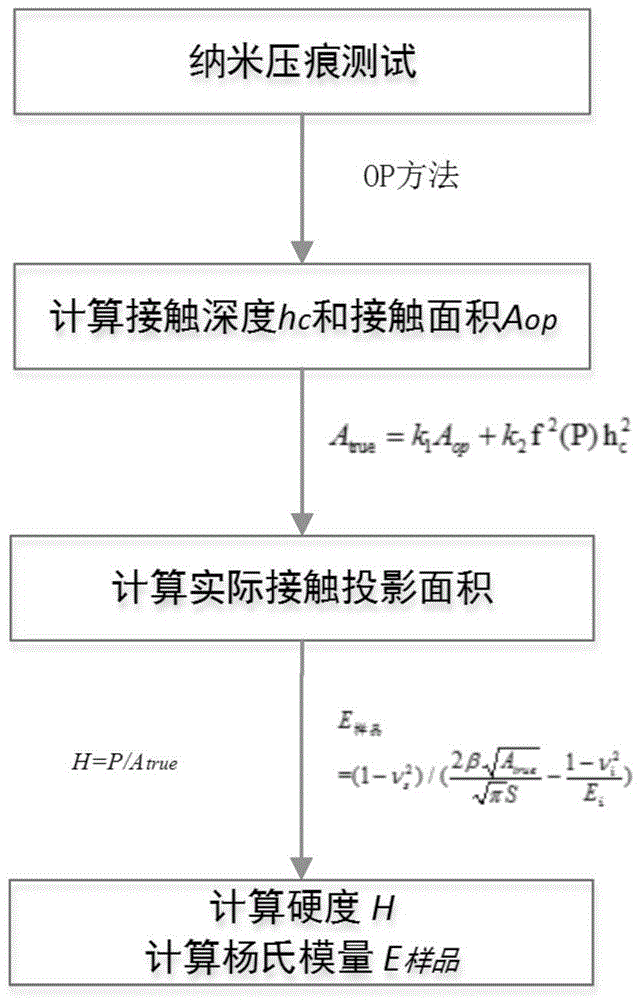

Method used

Image

Examples

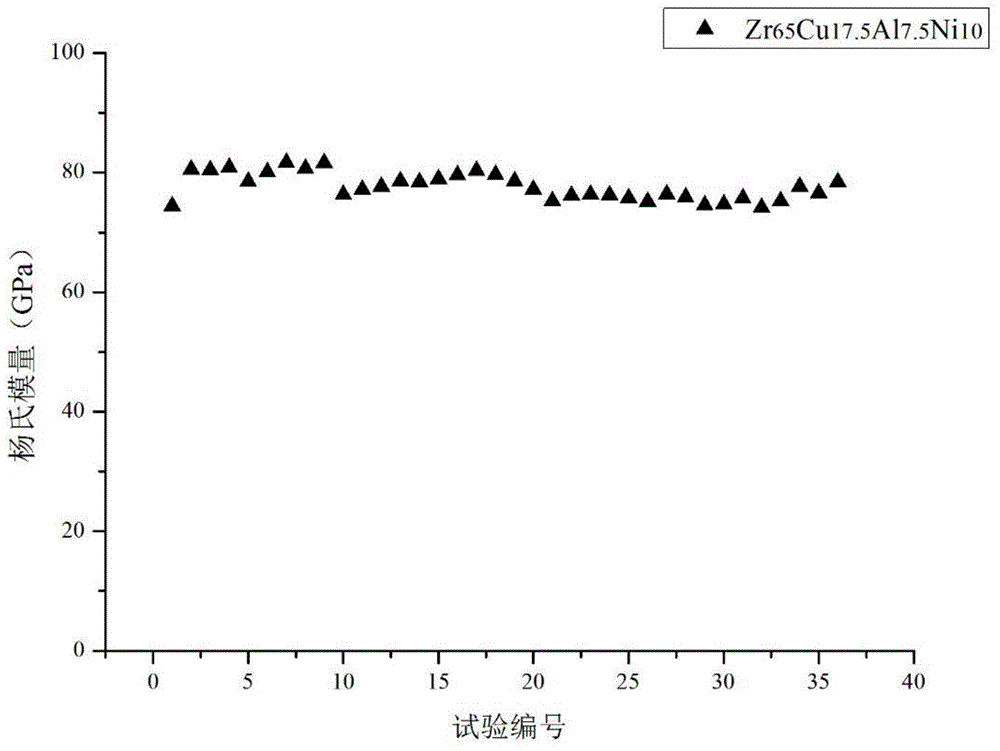

Embodiment 1

[0048] This embodiment is used to calculate Zr 65 Cu 17.5 Al 7.5 Ni 10 Young's modulus E of the amorphous alloy. Zr 65 Cu 17.5 Al 7.5 Ni 10 The amorphous alloy has obvious press-in convex characteristics. Its Young's modulus measured by ultrasonic resonance spectrum method is 80.56 ± 0.27GPa, which is consistent with literature (A.Inoue, A.Takeuchi, Recent development and application products of bulk glassy alloys, Acta Mater, 59(2011) 2243-2267. and M . Fukuhara, X.M.Wang, A.Inoue, F.X.Yin, Low temperature dependence of elastic moduli and internal friction for the glassyalloy Zr55Cu30Al10Ni5, PHYSICA STATUS SOLIDI-RAPID RESEARCHLETTERS, 1(2007) 220-222. Value, to compare with the measured value in this embodiment, so as to judge the accuracy of the method of this embodiment.

[0049] The preparation method of the amorphous alloy sample is to first obtain the rod material by the copper mold suction casting method, and then conduct the nano-indentation test after cutti...

Embodiment 2

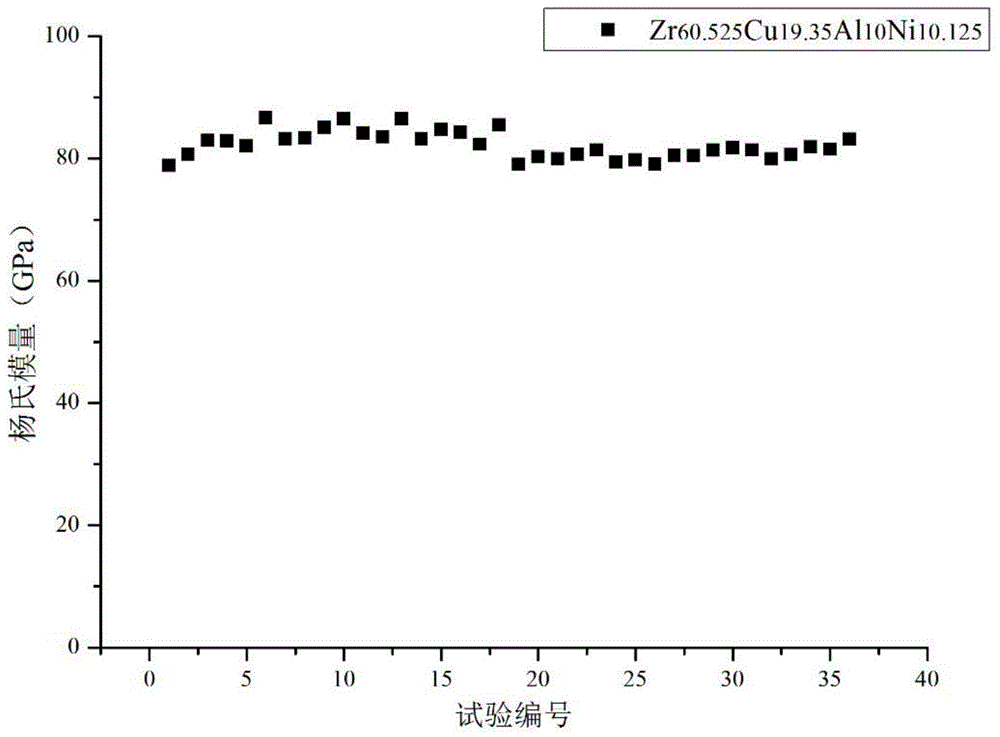

[0063] This embodiment is used to calculate Zr 60.525 Cu 19.35 Al 10 Ni 10.125 Young's modulus E of the amorphous alloy. Zr 60.525 Cu 19.35 Al 10 Ni 10.125 The amorphous alloy has obvious press-in convex characteristics. The Young's modulus 82GPa in the literature (W.H.Wang, The elastic properties, elastic models and elastic perspectives of metallic glasses, Prog MaterSci, 57(2012) 487-656.) was used as the standard value for comparison.

[0064]The preparation method of the amorphous alloy sample is to first obtain the rod material by the copper mold suction casting method, and then conduct the nano-indentation test after cutting, mounting the sample and grinding. In this example, each experimental process is located at a different position on the sample surface, and the indentations are separated by a certain distance to avoid mutual influence of test results.

[0065] S1: Carry out nano-indentation test on the tested sample, 36 times in total, 9 tests under the max...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com