Candy production system

A production system and candy bar technology, applied in general control systems, control/regulation systems, comprehensive factory control, etc., can solve the problems of waste of human resources, waste of resources, waste of human and material resources, etc., to reduce costs, reduce waste of resources, The effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

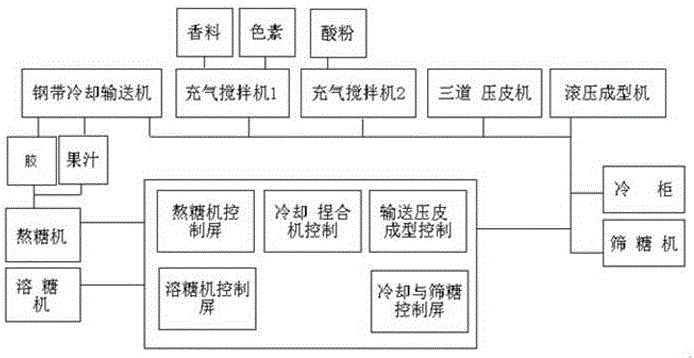

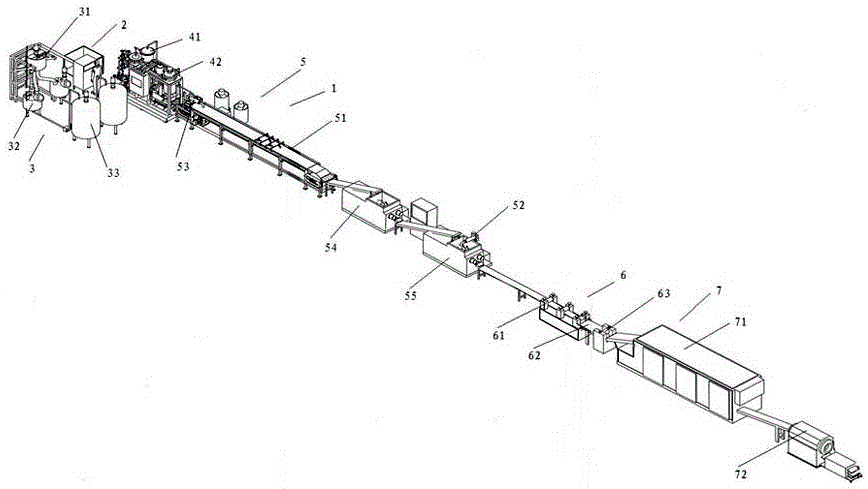

[0024] Such as figure 1 image 3 The shown candy block production system includes a frame 1 and a control system 2, and its innovation is that the production system also includes:

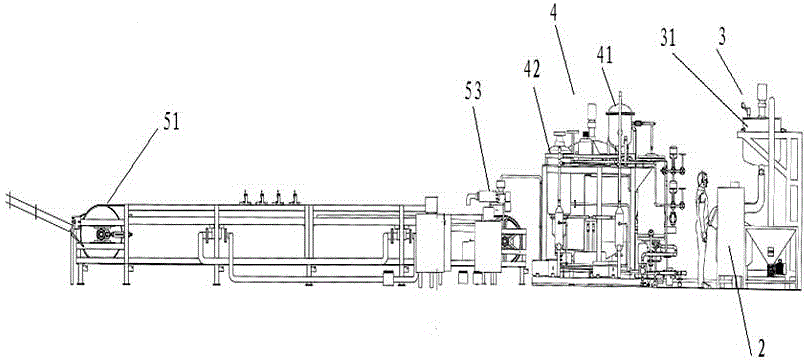

[0025] Weighing sugar dissolving mechanism 3: including raw material tank, batching tank 31, sugar dissolving tank 32 and sugar storage tank 33; sugar dissolving tank 32 and sugar storage tank 33 are provided with temperature sensor a and temperature sensor b; said batching tank 31 There is a raw material inlet main pipeline, which is connected to each raw material tank through a sub-pipe and the position of the sub-pipe connected to each main pipeline is controlled by a photoelectric switch; the mixing tank 31 is provided with a stirring tank driven by a motor The paddle, the output port of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com