Ultra-thin copper foil material

A technology of ultra-thin copper foil and copper foil, which is applied in the direction of metal pattern materials, printed circuit components, electrical components, etc., and can solve the problems of high price, insufficient adhesion between chemical copper and substrate, wrinkles and scratches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

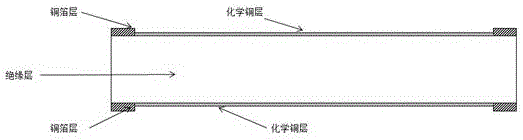

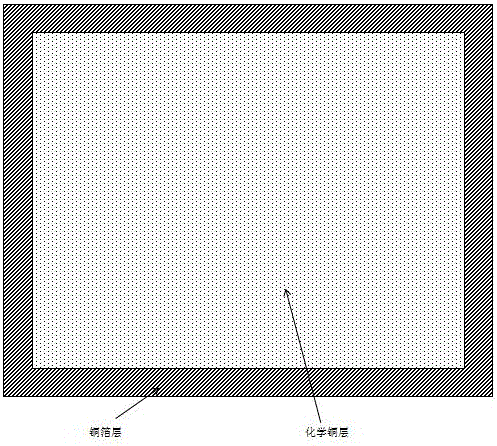

[0018] Specific implementation mode 1: ultra-thin copper foil copper clad laminate

[0019] Step A. First, assemble according to the normal production method of ordinary double-sided copper clad laminates. The size is 610mm*510mm. A piece of 2116 is used in the middle, the resin content is 53%, the thickness is 0.123mm, and a piece of 18um copper foil is placed on each side.

[0020] Step B. Vacuum lamination of the materials combined above, the lamination temperature is 110°C, the lamination time is 60 minutes, and the pressure is 35kg / cm 2 .

[0021] Step C. After lamination, seal the copper foil on both sides around the board with adhesive tape. The width of the adhesive tape is 15mm, and etch away the copper foil that is not covered by the adhesive tape.

[0022] Step D, tear off the tape, and directly carry out electroless copper deposition on the sheet, without removing the glue residue.

[0023] Step E, put the sheet into a vacuum laminator and perform lamination with...

specific Embodiment approach 2

[0025] Embodiment 2: Manufacture of resin-attached copper foil (RCC)

[0026] Step A, stacking, the material size is 610mm*510mm, three 18um copper foils and two 2116 prepregs are stacked, and the outermost copper foil faces the prepreg.

[0027] Step B. Vacuum lamination of the materials combined above, the lamination temperature is 110°C, the lamination time is 60 minutes, and the pressure is 35kg / cm 2 .

[0028] Step C. After lamination, seal the copper foil on both sides around the board with adhesive tape. The width of the adhesive tape is 15mm, and etch away the copper foil that is not covered by the adhesive tape.

[0029] Step D, tear off the tape, and directly carry out electroless copper deposition on the sheet, without removing the glue residue.

[0030] Step E, electroplating a layer of 1-9um copper layer on the board, or not electroplating.

[0031] Step F, tear the board from the middle, remove the middle layer of copper foil, and then become 2 sheets of resin...

specific Embodiment approach 3

[0032] Specific embodiment 3: used in the manufacture of laminated boards

[0033] According to the method of Embodiment 2, in step E, 1-3um copper is electroplated to manufacture resin-attached copper foil.

[0034] The resin-attached copper foil is vacuum-pressed on the board to be laminated according to the ordinary RCC method.

[0035] Laser drilling and blind hole copper plating are directly performed. Since the copper is very thin and uniform, there is no need to open a window for the laser hole or half-etch copper to thin it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com