A control method for a glass-wiping robot

A glass-wiping robot and a control method technology, applied in non-electric variable control, control/regulation system, automatic control of traveling motion, etc., can solve the problem of lack of remote-controlled glass-wiping robots, inflexible commutation, and unfavorable window-cleaning efficiency, etc. problems, to achieve the effect of improving glass wiping efficiency, improving cleaning efficiency, and high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

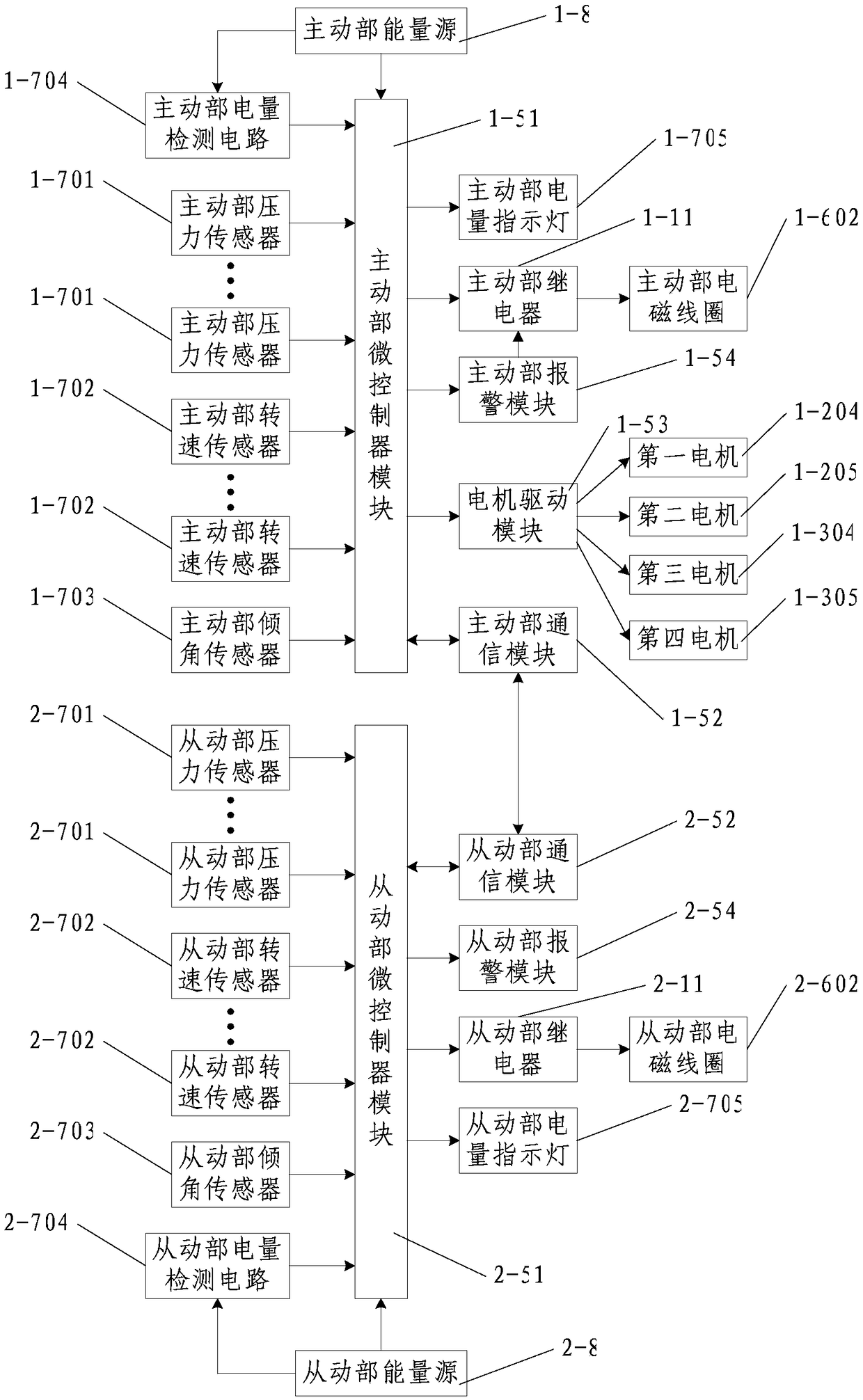

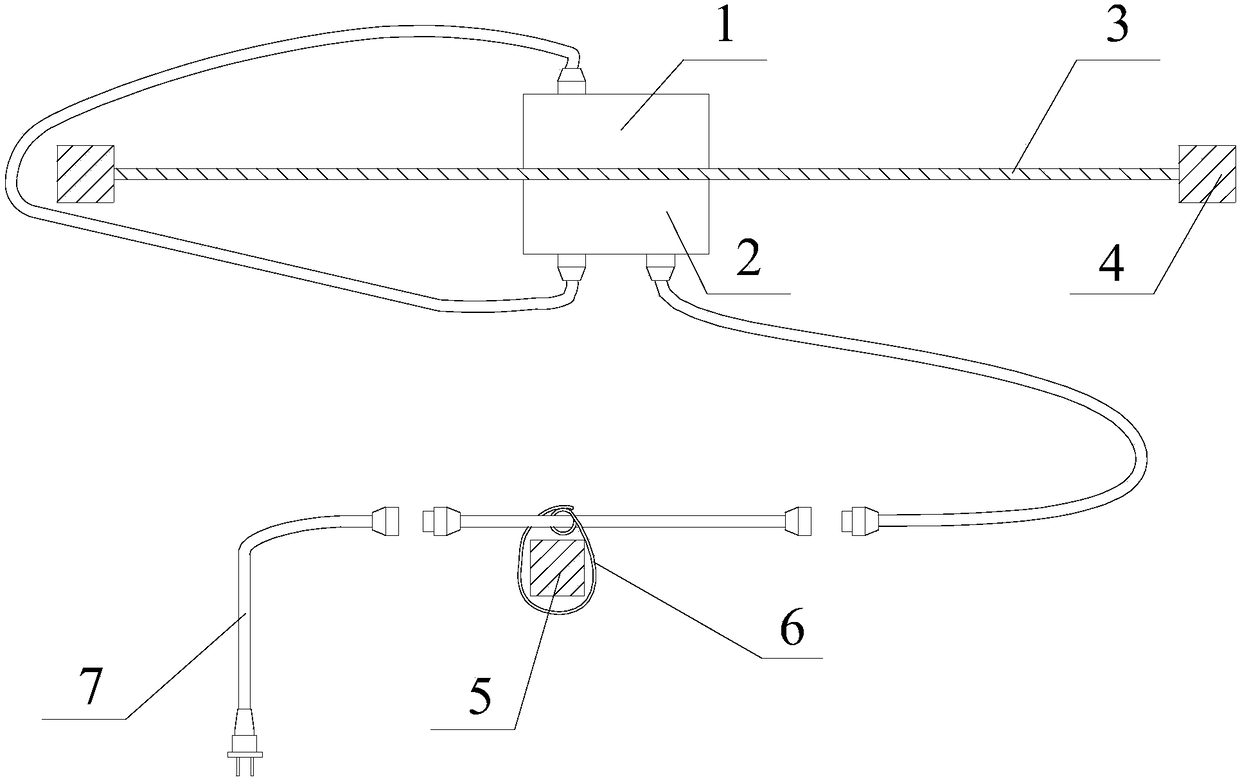

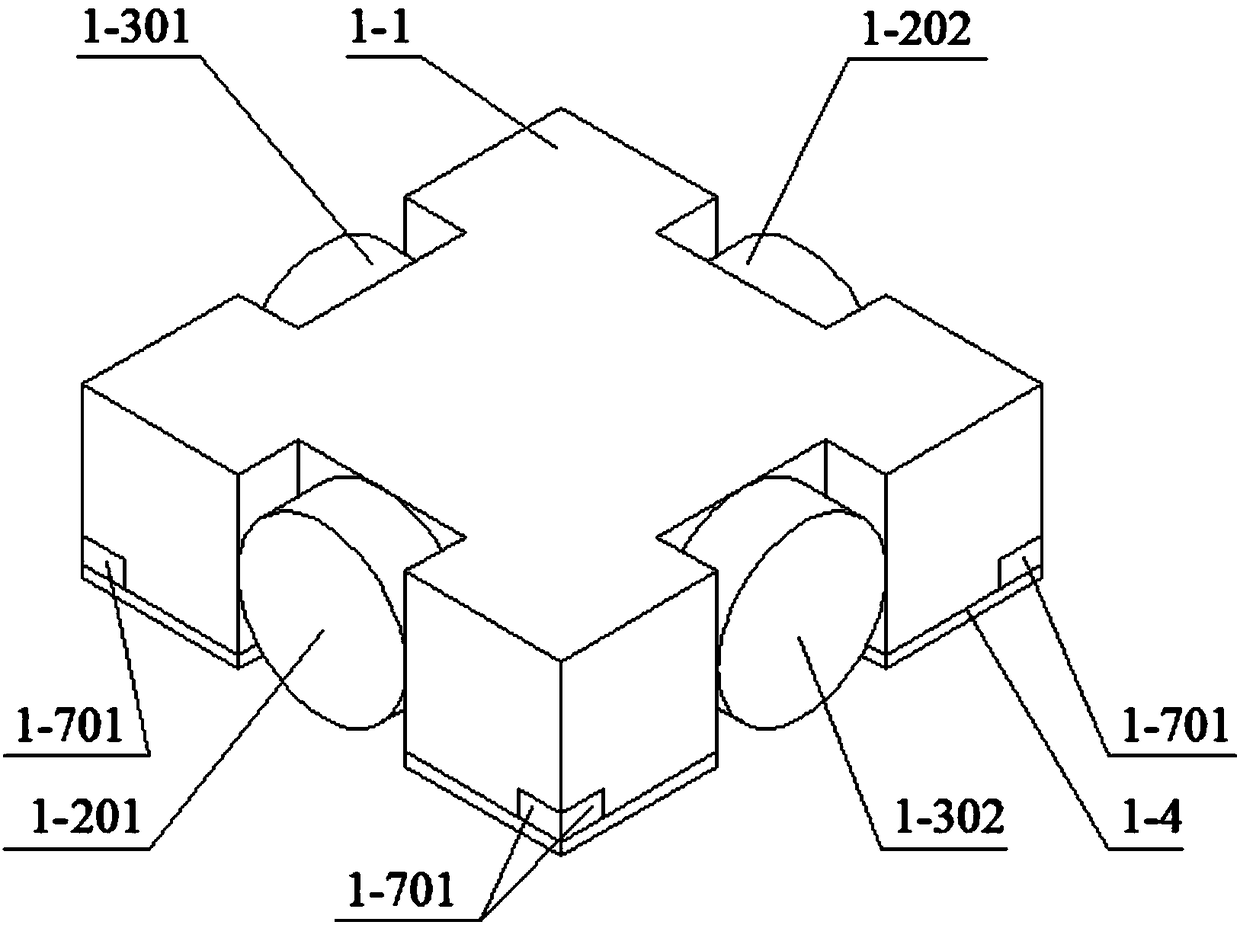

[0070] The glass-wiping robot of the present invention uses the control system, as figure 2 As shown, the glass-wiping robot includes a driving part 1 and a driven part 2 that are arranged on the inside of the glass 3 and the outside of the glass 3 and cooperate with each other, such as Figure 3 ~ Figure 7 As shown, the active part 1 includes a first driving wheel set, a second driving wheel set and a lifting unit of the active part, and the first driving wheel set includes a first motor 1-204 and a second motor 1-205. The second driving wheel set includes a third motor 1-304 and a fourth motor 1-305, and the lifting unit of the driving part includes an electromagnetic coil 1-602 of the driving part; Figure 8 ~ Figure 11 As shown, the driven part 2 includes a first driven wheel set, a second driven wheel set and a driven part lifting unit, and the driven part lifting unit includes a driven part electromagnetic coil 2-602; figure 1 As shown, the control system for the glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com