Permanent magnet synchronous motor direct driven energy-saving ball mill

A permanent magnet synchronous motor and direct drive technology, applied in the direction of controlling mechanical energy, electrical components, electromechanical devices, etc., can solve the problems of reduced efficiency, cumbersome transmission mechanism, and loss of transmission mechanism, so as to reduce frictional resistance and improve Energy saving and emission reduction, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

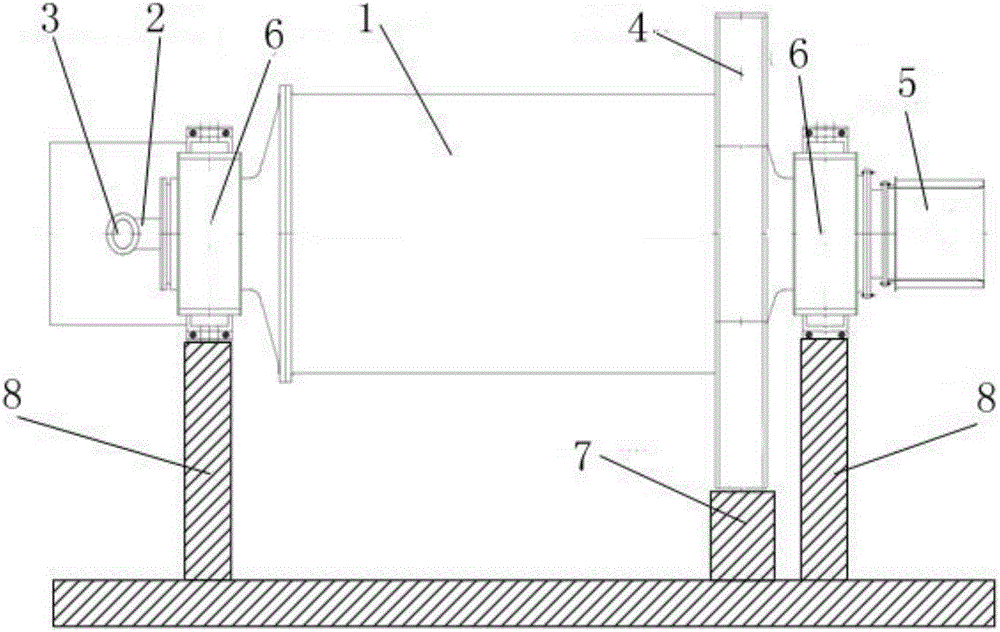

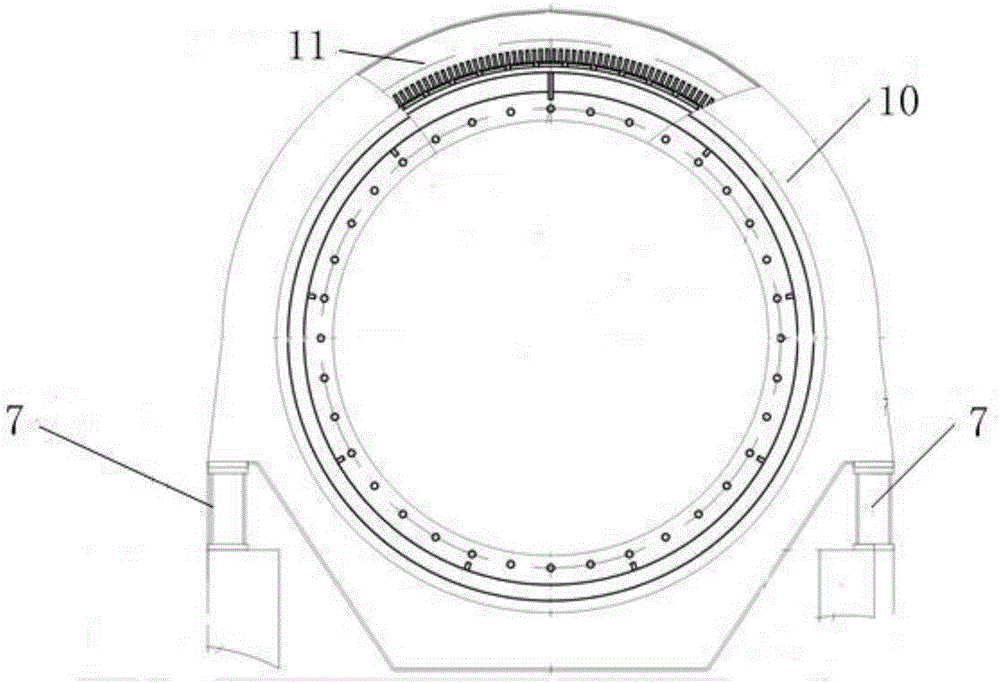

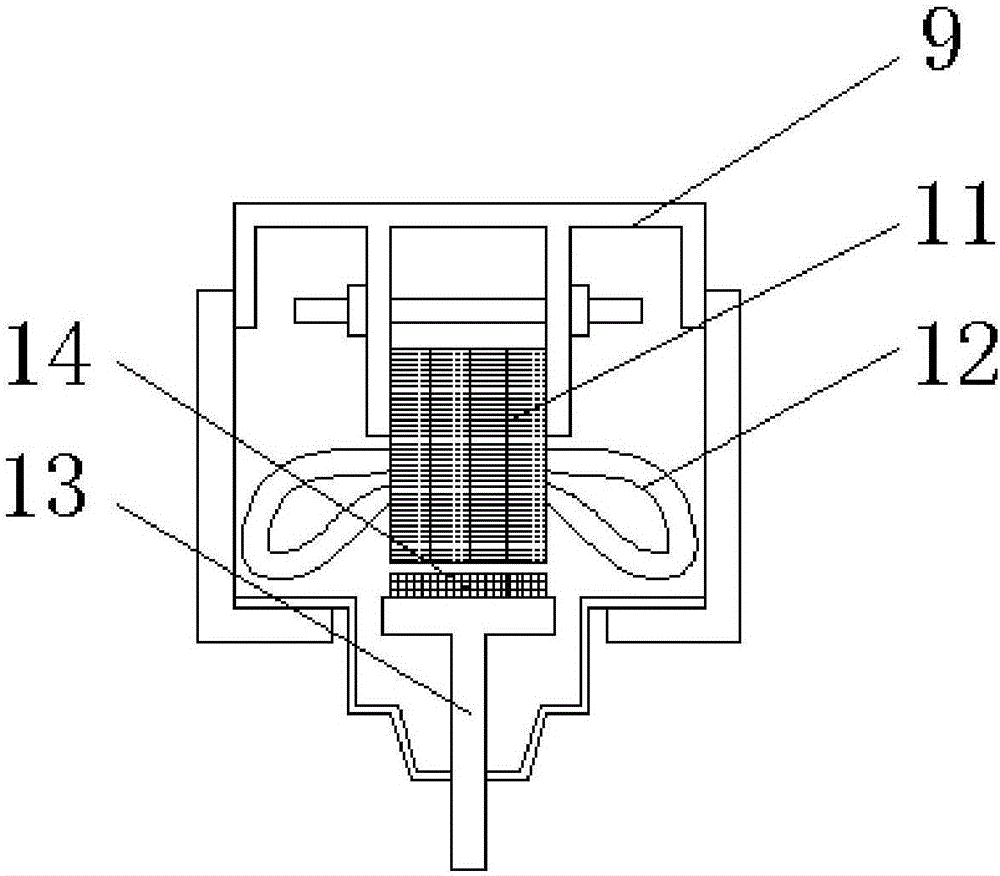

[0021] see figure 1 , figure 2 and image 3 , a permanent magnet synchronous motor direct-drive energy-saving ball mill, including a drum 1, the two ends of the drum 1 are respectively provided with a feed shaft 2 and a discharge end 5, and the drum 1 is sleeved in a sliding bearing 6 , the sliding bearing 6 is placed on the bearing support frame 8, the surface of the drum 1 is covered with a ring motor 4, the ring motor 4 is placed on the motor bracket 7, and the ring motor 4 includes a casing 10, a stator and The rotor, the casing 10 is fixed on the motor bracket 7, the stator core 11 and the stator winding 12 are arranged in the stator, the stator is fixed inside the casing 10, and the rotor is fixedly connected with the pole bracket 13 The permanent magnet poles 14, the pole bracket 13 is fixed on the shell of the drum 1.

[0022] In the present invention, the material enters from the feed shaft 2 and is discharged from the discharge end 5 . The rotating drum 1 is set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com