High voltage arc ignition circuit of wide voltage input argon arc welding machine

A wide voltage input, argon arc welding machine technology, applied in the field of argon arc welding, can solve the problems such as the arc ignition success rate cannot be 100%, the arc ignition effect is affected, etc., to achieve reliable arc ignition, more work, stable and reliable work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several changes and improvements without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

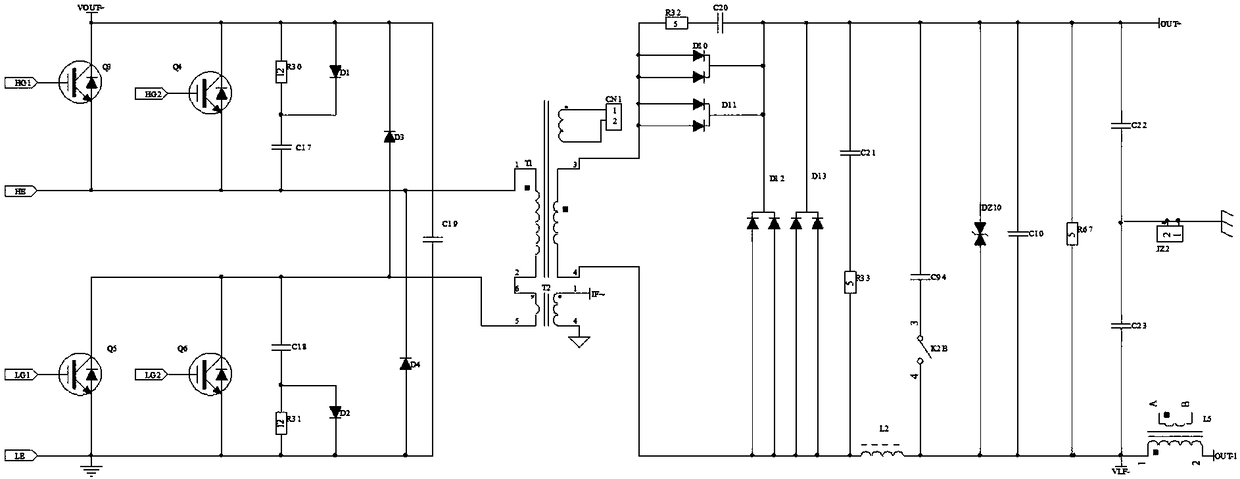

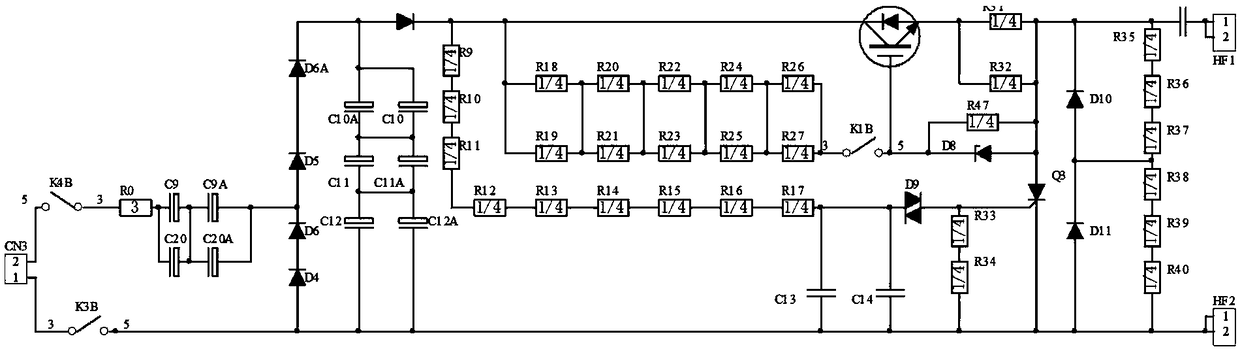

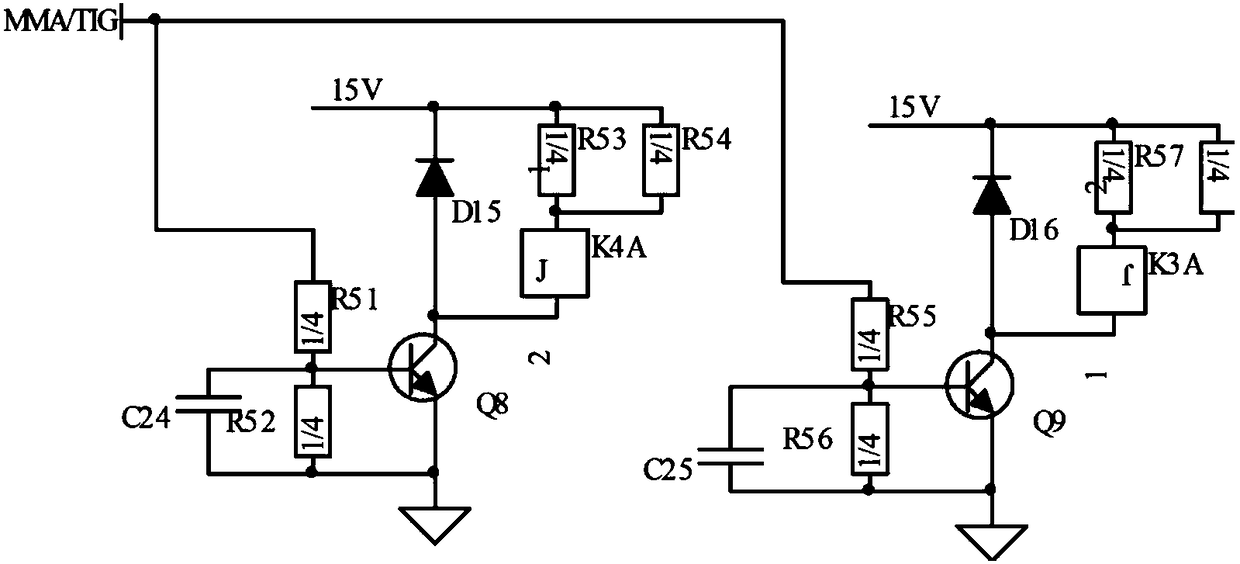

[0026] According to the present invention, the high-voltage arc starting circuit of the wide-voltage input argon arc welding machine includes: the main circuit circuit of the inverter welding machine, and the high-voltage arc starting circuit;

[0027] The main circuit circuit of the inverter welding machine adopts a dual-tube single-ended forward topology circuit, which inverts the rectified DC power into high-frequency square wave power, and then rectifies it into low-voltage power required by the invert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com