Welding device and method for preventing welding angular distortion

A welding device and welding angle technology, applied in welding equipment, high-frequency current welding equipment, metal processing equipment, etc., can solve the problems affecting the installation accuracy and bearing capacity of parts, increase design costs, reduce work efficiency, etc., and achieve a simple structure. , The effect of eliminating residual deformation and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

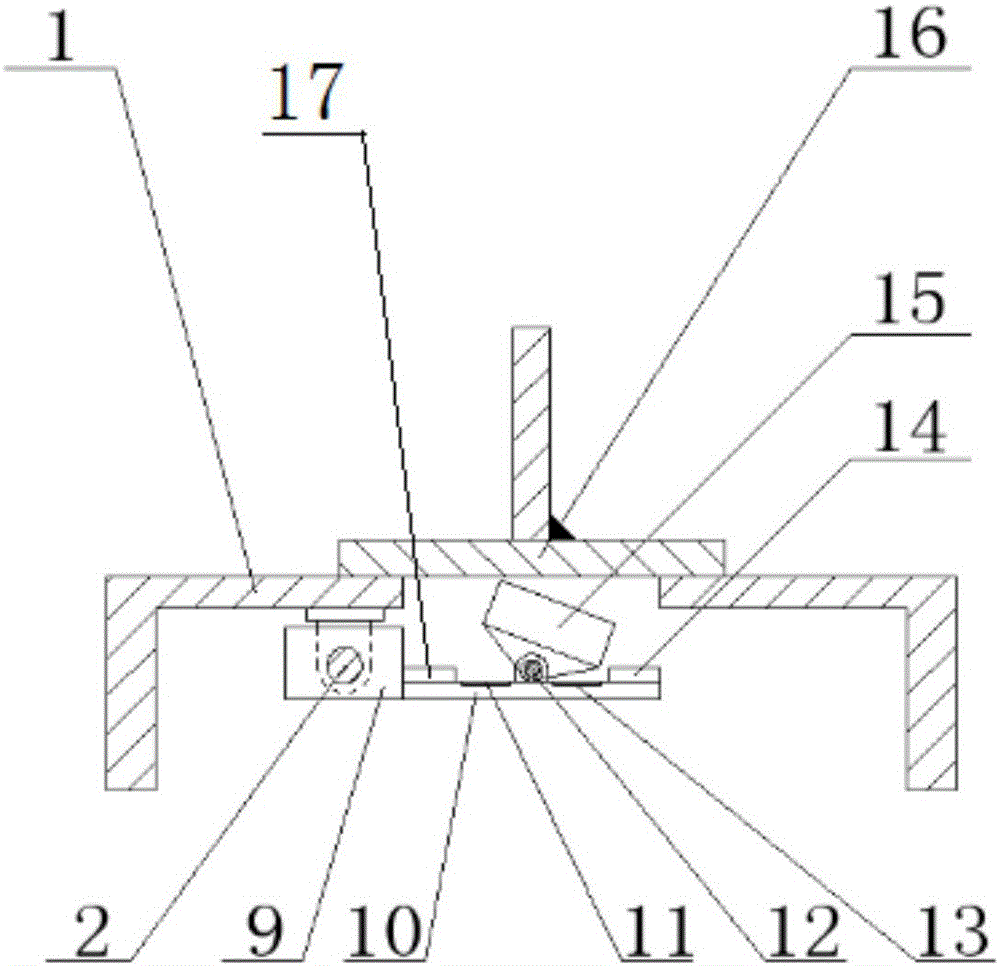

[0044] The deformation in the welding process is mainly caused by the residual stress caused by the non-uniform cooling of the heat-affected zones on both sides of the weldment 16 after the welding is completed. For x-shaped grooves, symmetrical welding can reduce welding deformation, while for asymmetrical grooves such as v-shaped T-shaped grooves, it is impossible to adopt symmetrical welding, which leads to large residual deformation after welding. Therefore, the present invention provides a kind of welding device, by adopting the method of reducing the deformation of the welding angle by induction heating on the back side of the welding part, applying a heat source close to the welding input on the back side of the weldment 16, by making the two sides of the weldment 16 The side undergoes a similar welding thermal cycle process, thereby reducing the residual deformation caused by welding.

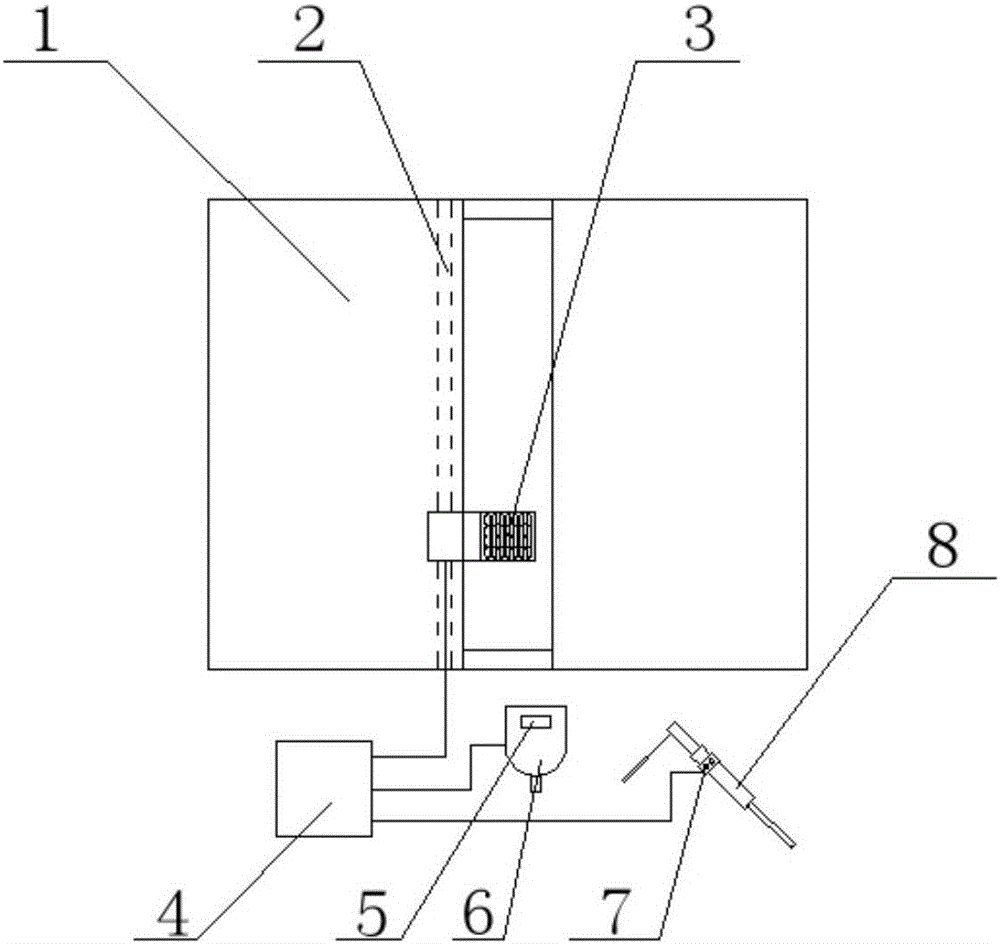

[0045] Specifically, the welding device includes a welding platform 1 , a guide rai...

Embodiment 2

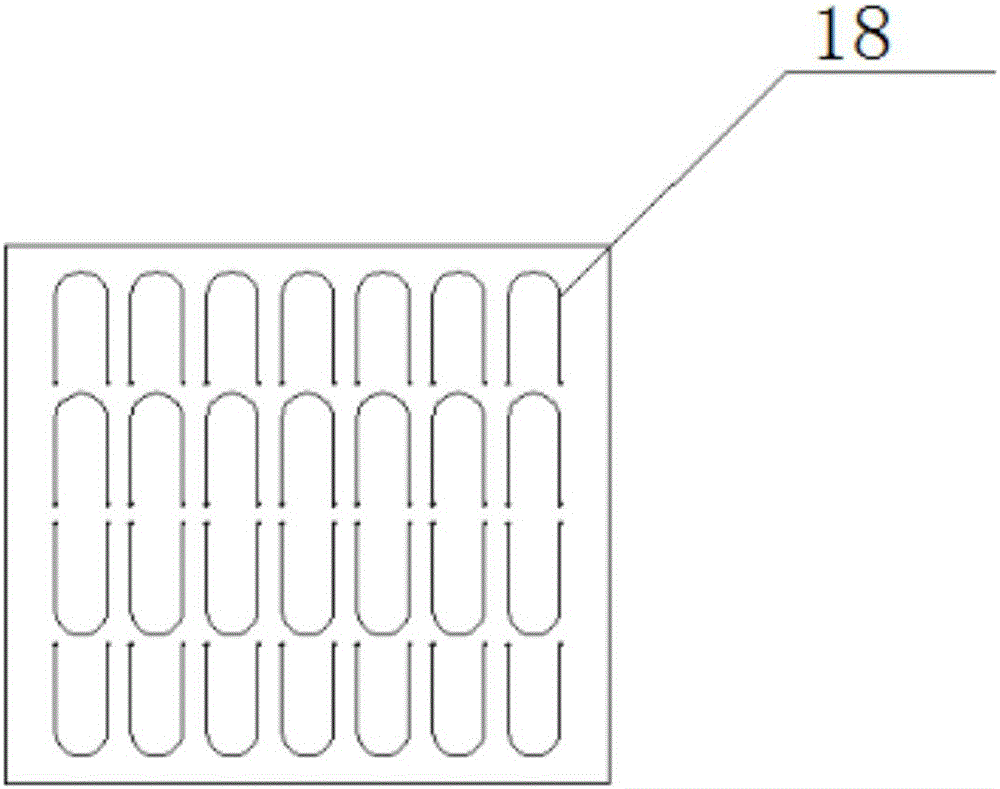

[0048] The form of weldment joint with welding is T-shaped joint, the size of the bottom plate is 1000mmX500mmX8mm, and the size of the longitudinal plate is 500Xmm500mmX5mm. In order to match the welding angle, set the heating head to swing 15 degrees through the control box (such as figure 1 ), the welding method adopts manual arc welding, the first welding current is 105-120A, the voltage is 20-22V, the welding speed is 75-90mm / min, the line energy is 1.4-2.11KJ / mm, and the induction coil 17 for heating is set as Figure 4 As shown, the current is 5-8A, and the frequency is 20KHz. Welding personnel use the controller to cooperate with the feedback screen to keep the movement of the heating head in sync with the movement of the welding tongs. After the welding is completed, the angular deformation is approximately equal to zero, while the angular deformation of the weldment without heating measures on the back of the weldment is about 2 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com