Method for repairing broken tooth chain wheel

A repair method and sprocket technology, applied in the field of sprocket repair, can solve problems such as poor welding strength of broken tooth sprockets, and achieve the effects of enhanced connection strength, high strength and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

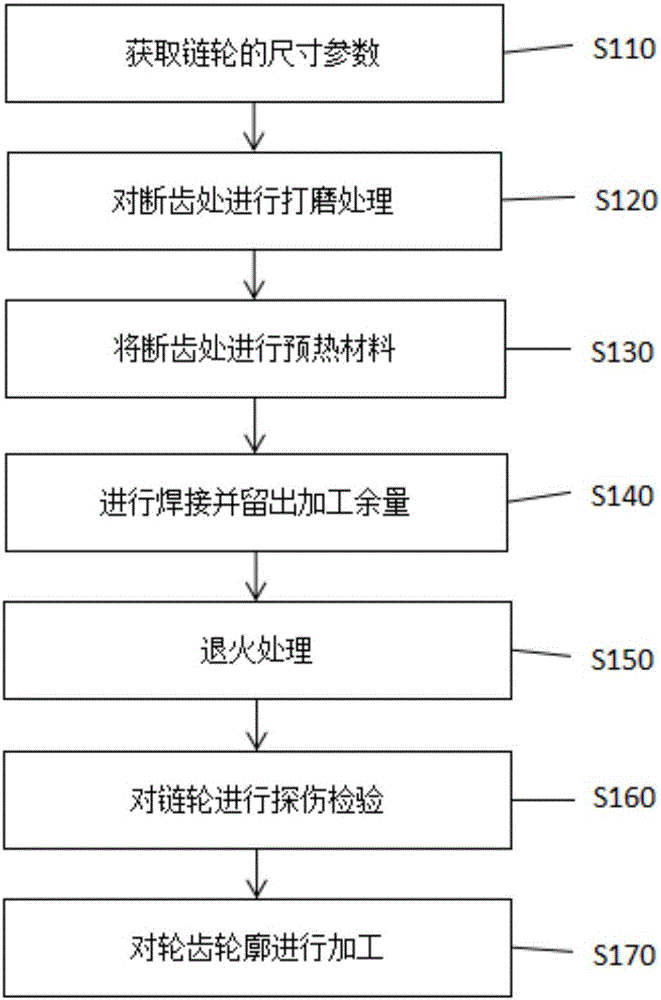

[0028] The invention provides a method for repairing a sprocket with broken teeth, which is used for repairing the unusable sprocket due to broken teeth. This method comprises the steps:

[0029] Step 1 S110: Obtain the size parameter and material of the sprocket.

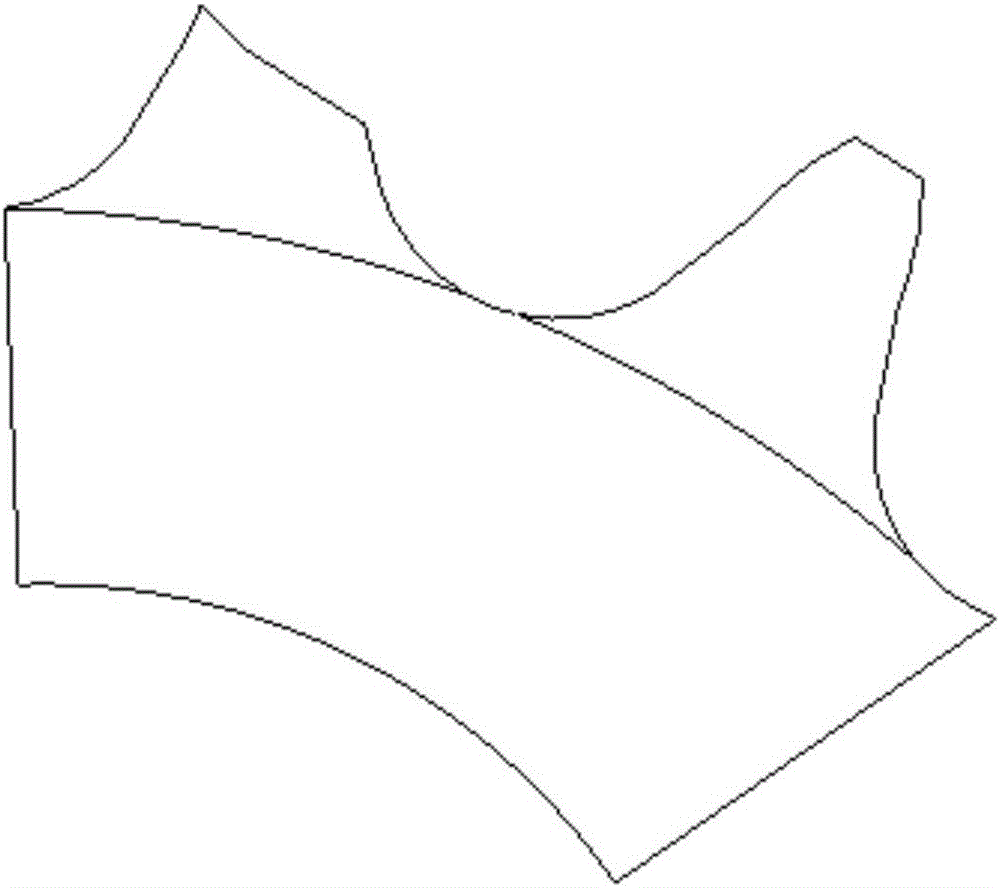

[0030] The size parameters of the sprocket, including the profile of the tooth shape, can be obtained according to the sprocket model, drawings and other information, so that the repaired sprocket can meet the size requirements. As a preferred option, in many cases, the sprocket has broken teeth after a long period of use, and the original drawing of the sprocket cannot be found. This requires surveying and mapping to obtain the outline of the sprocket teeth. Usually, a three-coordinate meter or a projector can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com