TPU composite material for oil storage bag

A composite material, oil storage bag technology, applied in applications, household appliances, household packaging, etc., can solve the problem of poor high and low temperature resistance and tensile strength, unsatisfactory peel strength and oil resistance, and unenvironmental materials, etc. problem, to achieve the effect of good wear resistance and tensile strength, high peel strength and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

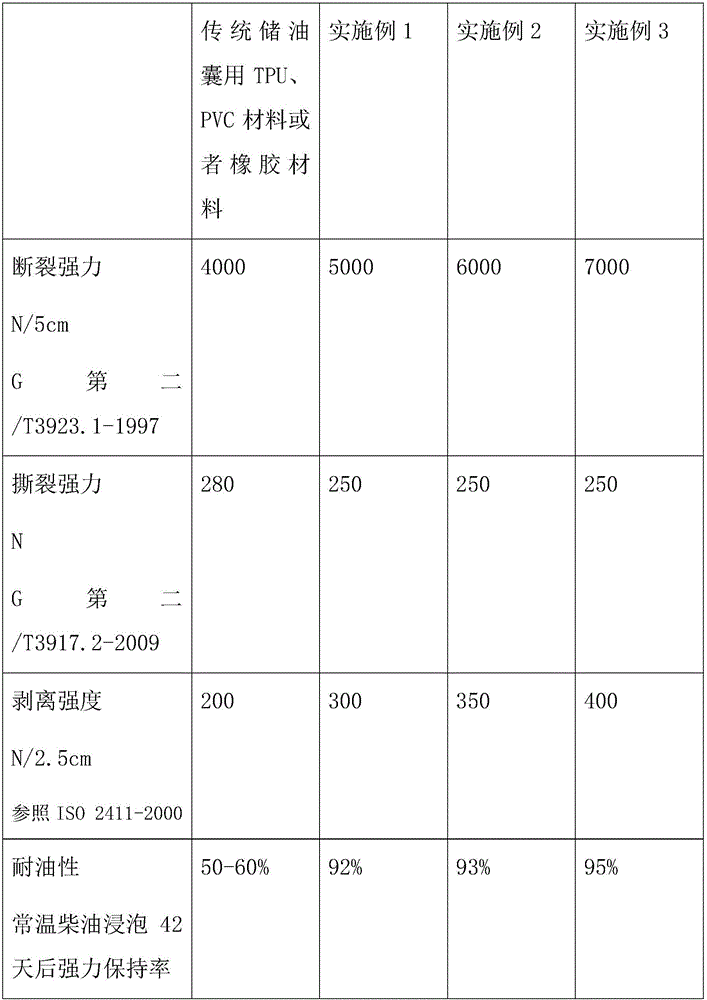

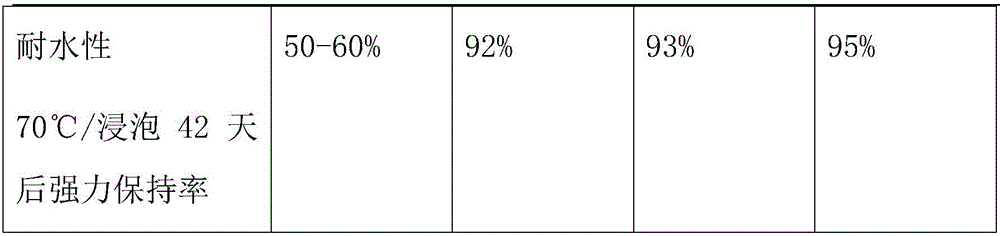

Examples

Embodiment 1

[0021] A TPU composite material for an oil storage bag, including from top to bottom: a first surface, an adhesive layer, a skeleton layer, an adhesive layer, and a second surface.

[0022] The first surface includes polyester TPU (385E, with a hardness of 85A), and the thickness of the first surface is 0.3mm.

[0023] The first side further includes an antioxidant (Chinox 20N), and the mass ratio of the antioxidant to the polyester TPU is 0.03%:1.

[0024] The first surface further includes a carbodiimide anti-hydrolysis agent (UN-150), and the mass ratio of the carbodiimide anti-hydrolysis agent to the polyester TPU is 0.03%:1.

[0025] The second surface includes polyether type TPU (9385, with a hardness of 85A), and the thickness of the second surface is 0.3mm.

[0026] The second surface also includes an antioxidant (Chinox 20N) and an anti-UV additive (U2877), the mass ratio of the antioxidant to the polyether TPU is 0.03%:1, and the anti-UV additive The mass ratio of ...

Embodiment 2

[0030] A TPU composite material for an oil storage bag, including from top to bottom: a first surface, an adhesive layer, a skeleton layer, an adhesive layer, and a second surface.

[0031] The first surface includes polyester TPU (KDT-1190ARE, with a hardness of 90A), and the thickness of the first surface is 0.32mm.

[0032] The first surface further includes an antioxidant (1010), and the mass ratio of the antioxidant to the polyester TPU is 0.05%:1.

[0033] The first surface also includes a carbodiimide anti-hydrolysis agent (Stabilizer 7000), and the mass ratio of the carbodiimide anti-hydrolysis agent to the polyester TPU is 0.05%:1.

[0034] The second surface includes polyether TPU (KDT2385ARE, hardness 90A), and the thickness of the second surface is 0.32mm.

[0035] The second surface also includes an antioxidant (1010) and an anti-UV auxiliary (UVB-1260), the mass ratio of the antioxidant to the polyether TPU is 0.032:1, and the anti-UV auxiliary The mass ratio o...

Embodiment 3

[0039] A TPU composite material for an oil storage bag, including from top to bottom: a first surface, an adhesive layer, a skeleton layer, an adhesive layer, and a second surface.

[0040] The first surface includes polyester TPU (EX90A, hardness 90A), and the thickness of the first surface is 0.35mm.

[0041] The first surface further includes an antioxidant (1010), and the mass ratio of the antioxidant to the polyester TPU is 0.1%:1.

[0042] The first surface also includes a carbodiimide anti-hydrolysis agent (UN-150), and the mass ratio of the carbodiimide anti-hydrolysis agent to the polyester TPU is 0.1%:1.

[0043] The second surface includes polyether TPU (KDT2385ARE, hardness 90A), and the thickness of the second surface is 0.35 mm.

[0044] The second surface also includes an antioxidant (Chinox 20N) and an anti-UV auxiliary (U2877), the mass ratio of the antioxidant to the polyether TPU is 0.1%:1, and the anti-UV auxiliary The mass ratio of the agent to the polye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com