Full-automatic machine for folding and packaging of facial masks

A packaging machine, fully automatic technology, used in packaging, folding thin materials, transportation and packaging, etc., can solve the problems of asymmetry, stability, poor reliability, easy to unravel, etc., to achieve high speed, improve efficiency and reliability. , the effect of simplifying the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

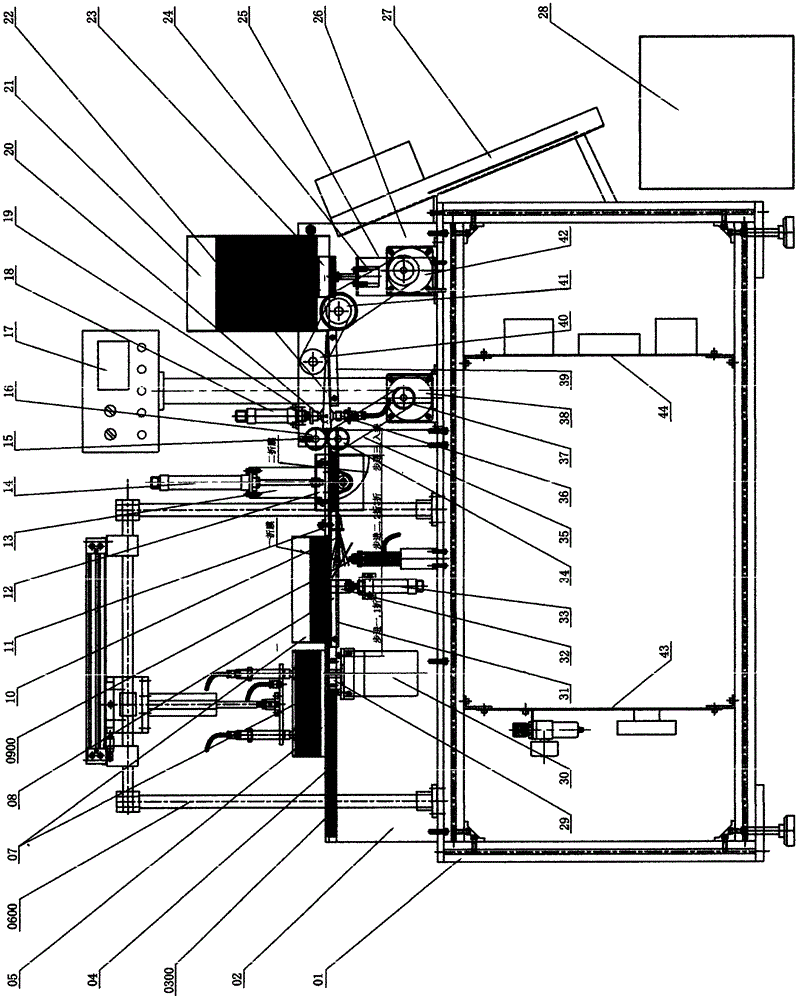

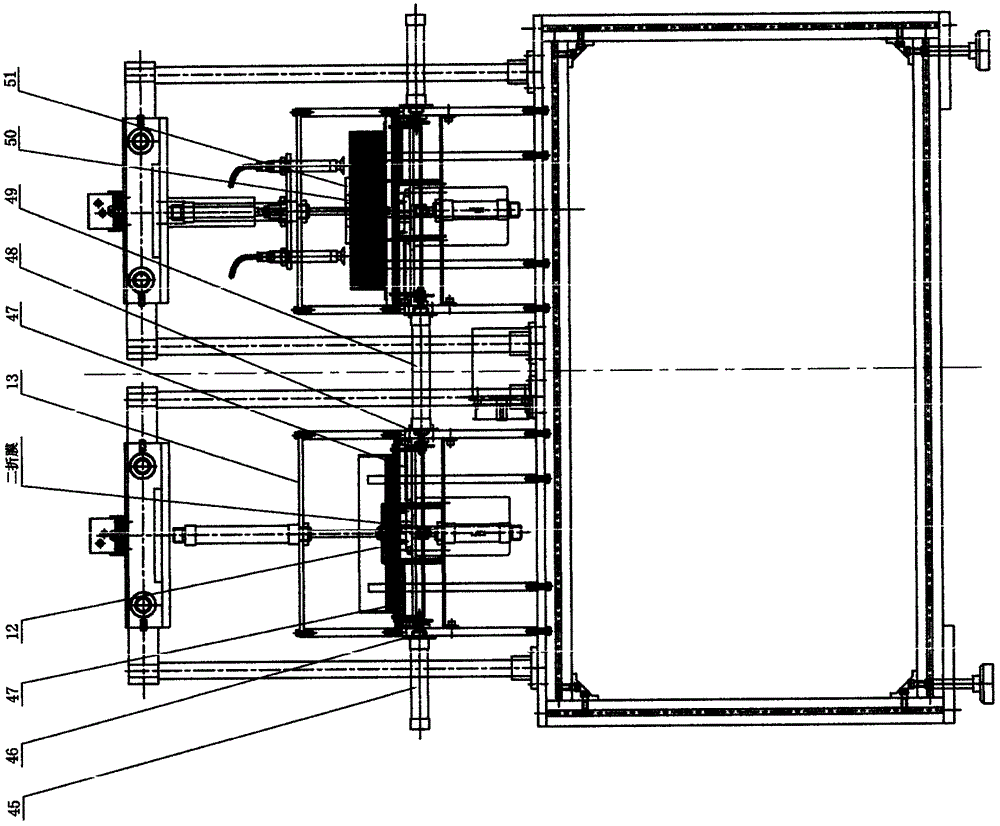

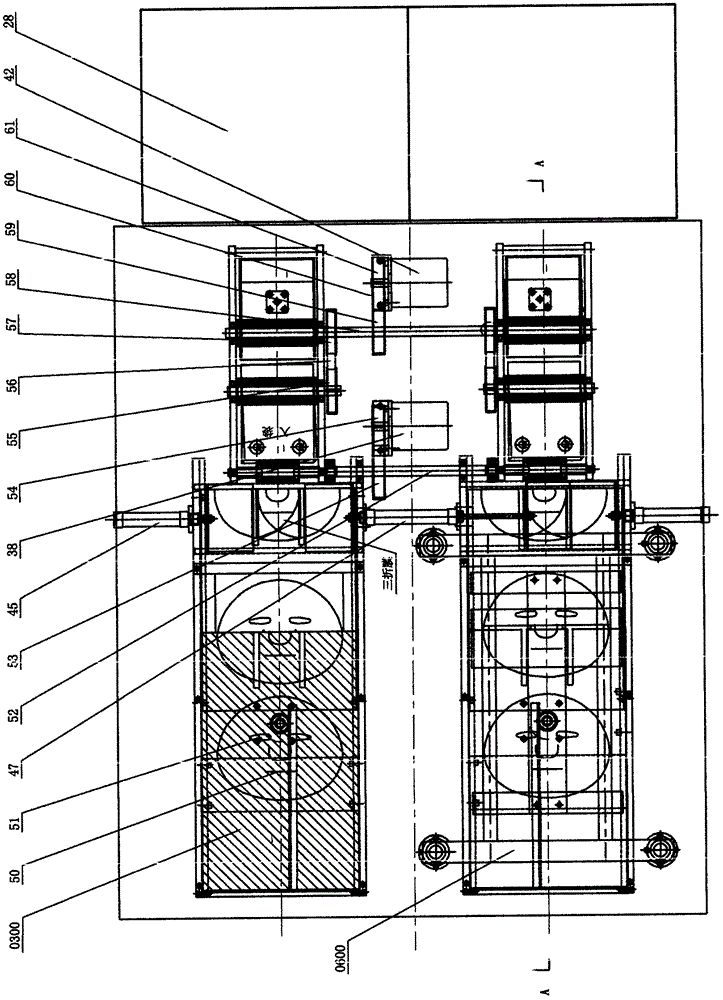

[0025] The present invention is realized in the following ways:

[0026] Its feature is that the present invention is folded in the mode B, such as Figure 9 , as shown in the figure of the B folding style. It adopts stepping line linear motion, adopts horizontal reverse folding, and the plastic film is stacked inside, and the entire folding process can be completed on one folding film board, such as figure 1 , figure 2 , image 3 , Figure 4 Shown:

[0027] 1. The machine (01)) is equipped with a folding workbench (02), a packaging workbench (26), an operating system (17), a pneumatic system (43), an electrical control System (44), discharge box (28) is equipped with in this machine platform (01)) right side, as figure 1 Shown:

[0028] 2. The folding film plate 1 (0300) is also installed on the folding workbench (02), which is composed of a positioning pin (0301), a film folding groove (0302), and a rack (04), such as Figure 5 Shown: it is driven by stepper motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com