Primary sealing device of compression plate type lightning protection oil storage tank

A technology for compressing plates and oil storage tanks, applied in packaging, transportation and packaging, containers, etc., can solve the problems of secondary environmental pollution, no lightning protection, poor compensation ability, etc., and achieve long service life and good sealing. , the effect of strong compensatory ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

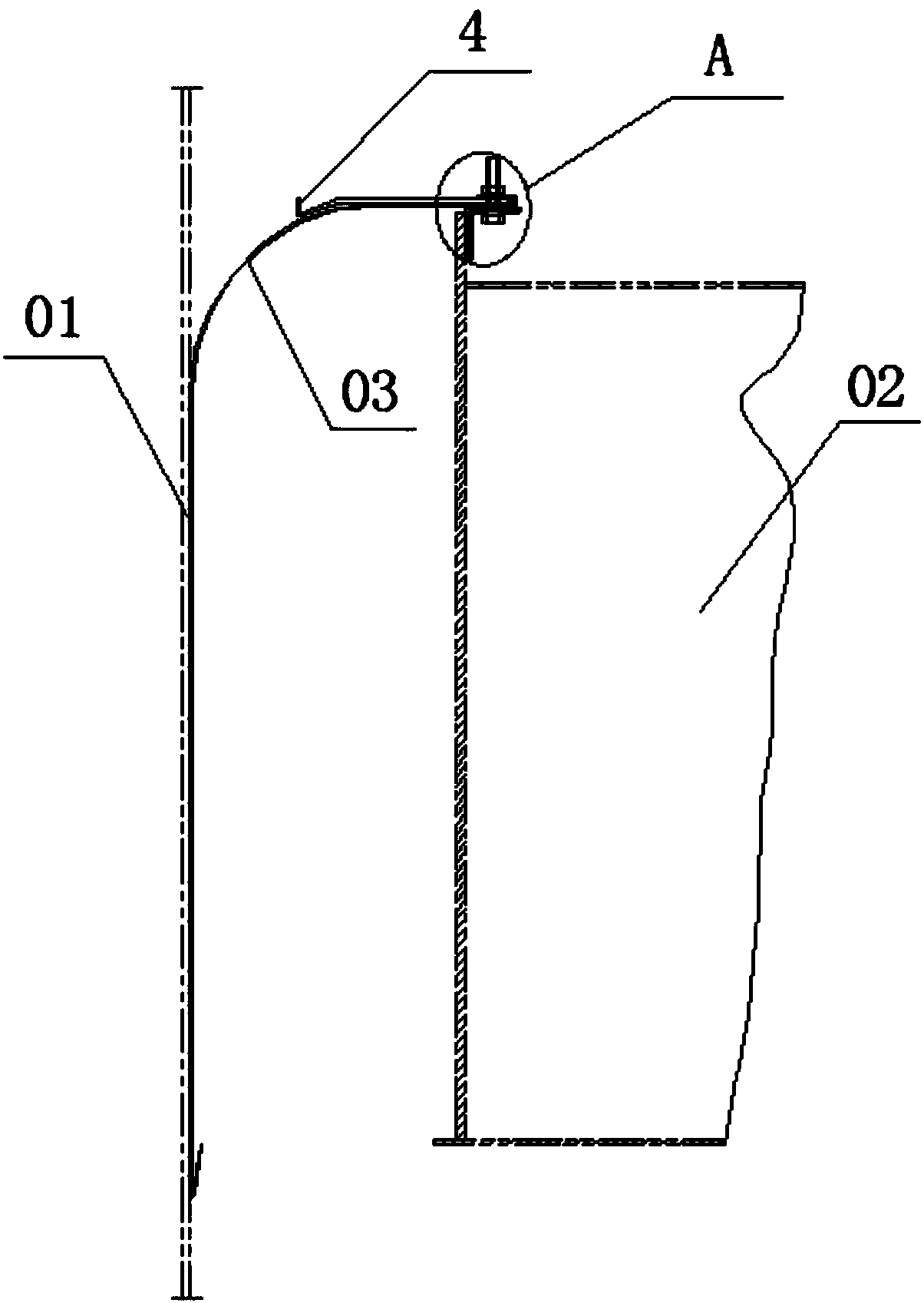

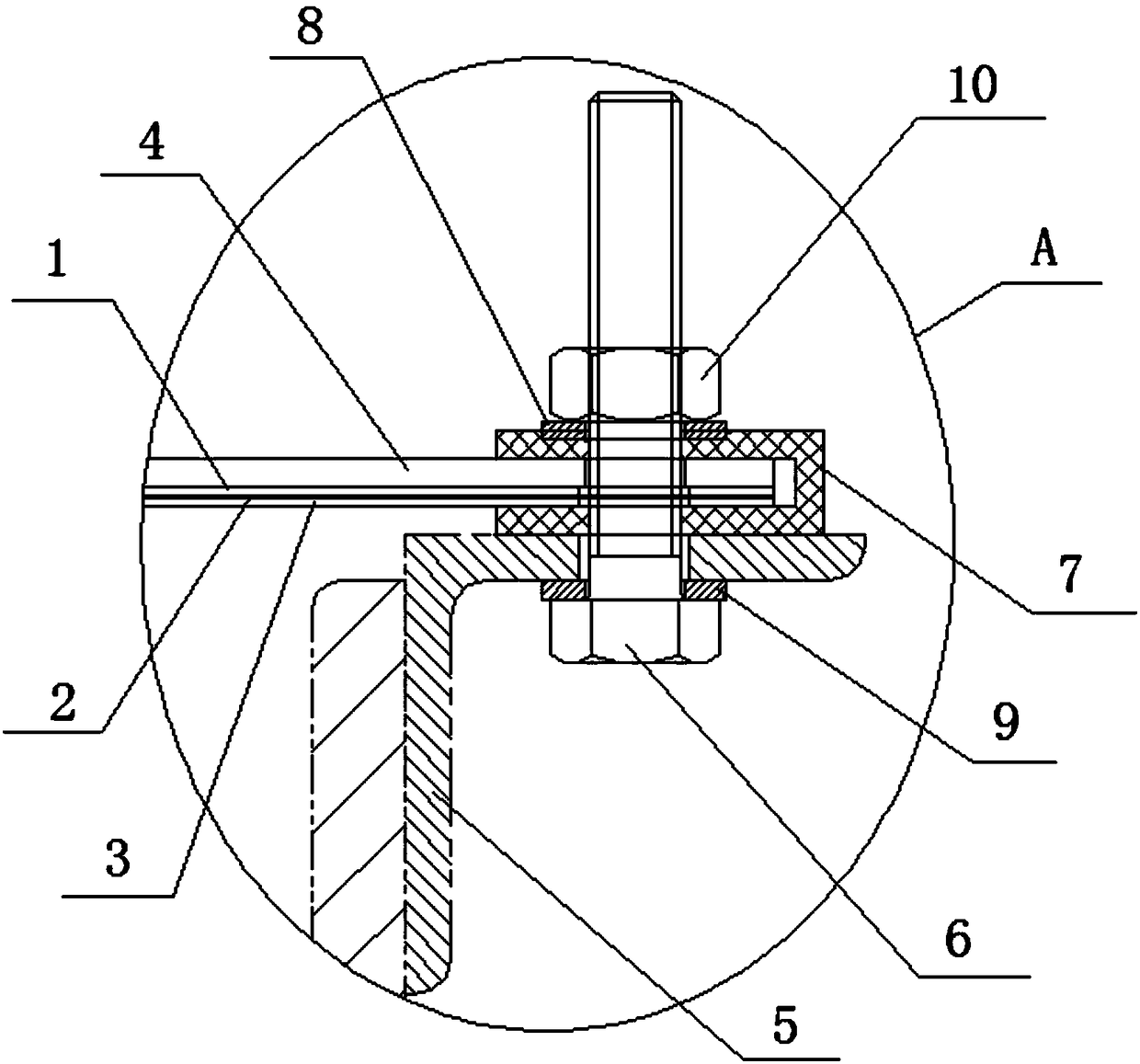

[0052] See figure 1 and figure 2 , the primary sealing device of the compression plate type lightning protection oil storage tank, including the ring-shaped compression plate 03 which is sequentially stacked by a stainless steel sealing plate 1, a gas barrier film 2 (polytetrafluoroethylene) and a stainless steel compression spring plate 3, and a buffer Plate 4, a plurality of connecting angle steels 5 and stainless steel connecting bolts 6; the buffer plate 4 is arranged above the inner end of the compression plate 03, and the inner end of the buffer plate 4 and the inner end of the compression plate 03 are laminated and wrapped with conductive rubber 7, The outer end of the compression plate 03 is bent downward, and the end surface of the stainless steel sealing plate 1 is close to the inner wall of the oil storage tank 01 under the elastic force of the stainless steel compression spring plate 3, and the immersion depth is not less than 100mm, and the vertical part of the c...

Embodiment 2

[0056] See Figure 4 and Figure 5 , the primary sealing device of the compression plate type lightning protection oil storage tank, including the ring-shaped compression plate 03 which is sequentially stacked by a stainless steel sealing plate 1, a gas barrier film 2 (polytetrafluoroethylene) and a stainless steel compression spring plate 3, and a buffer Plate 4, a plurality of connecting angle steels 5 and stainless steel connecting bolts 6; the buffer plate 5 is arranged above the inner end of the compression plate 03, and the inner end of the buffer plate 4 and the inner end of the compression plate 03 are laminated and wrapped with conductive rubber 7, The outer end of the compression plate 03 is bent downward, and the end surface of the stainless steel sealing plate 1 is close to the inner wall of the oil storage tank 01 under the elastic force of the stainless steel compression spring plate 3, and the depth of immersion is not less than 100mm. Part of it is fixedly con...

Embodiment 3

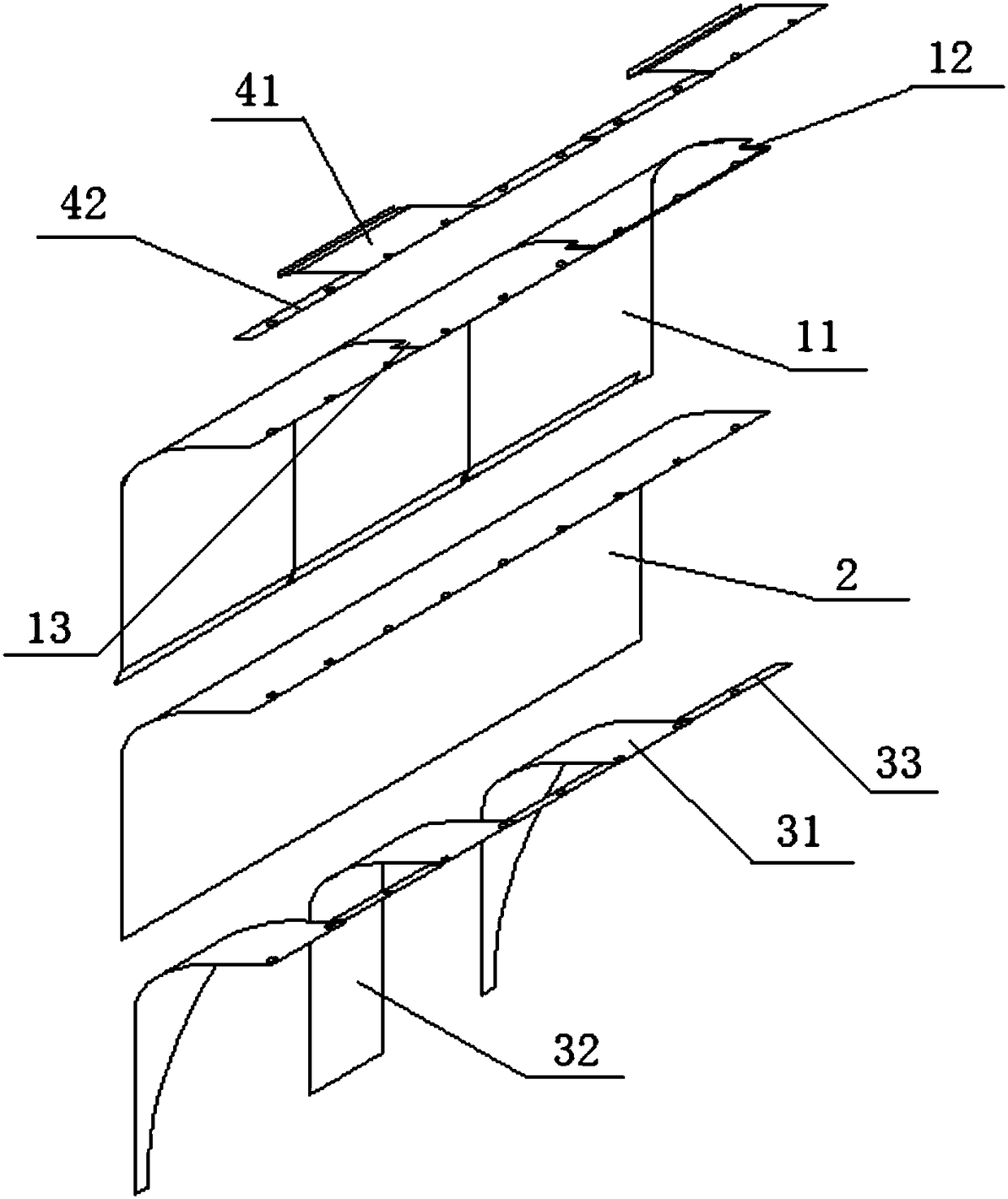

[0058] See Figure 6 and Figure 7 , the primary sealing device of the compression plate type lightning protection oil storage tank, including the ring-shaped compression plate 03 which is sequentially stacked by the stainless steel sealing plate 1, the gas barrier film 2 (polytetrafluoroethylene) and the stainless steel compression spring plate 3, and the ring-shaped The magnetic conductive rubber film 11, the buffer plate 4, a plurality of connecting angle steel 5 and stainless steel connecting bolts 6; the inner end of the compression plate 03 is wrapped with conductive rubber 7, the outer end of the compression plate 03 is bent downward and its stainless steel sealing plate 1 The end surface is close to the inner wall of the oil storage tank 01 under the elastic force of the stainless steel compression spring plate 3, the depth of immersion is not less than 100mm, the inner end of the magnetic conductive rubber film 11 is located above the inner end of the compression plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com