Cross-linked chitosan microspheres, and preparation method and application thereof

A technology for cross-linking chitosan and chitosan, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of difficult removal of dye pollutants, narrow pH value range, weak bridging ability, etc. The effect of chemical stability, low equipment requirements, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

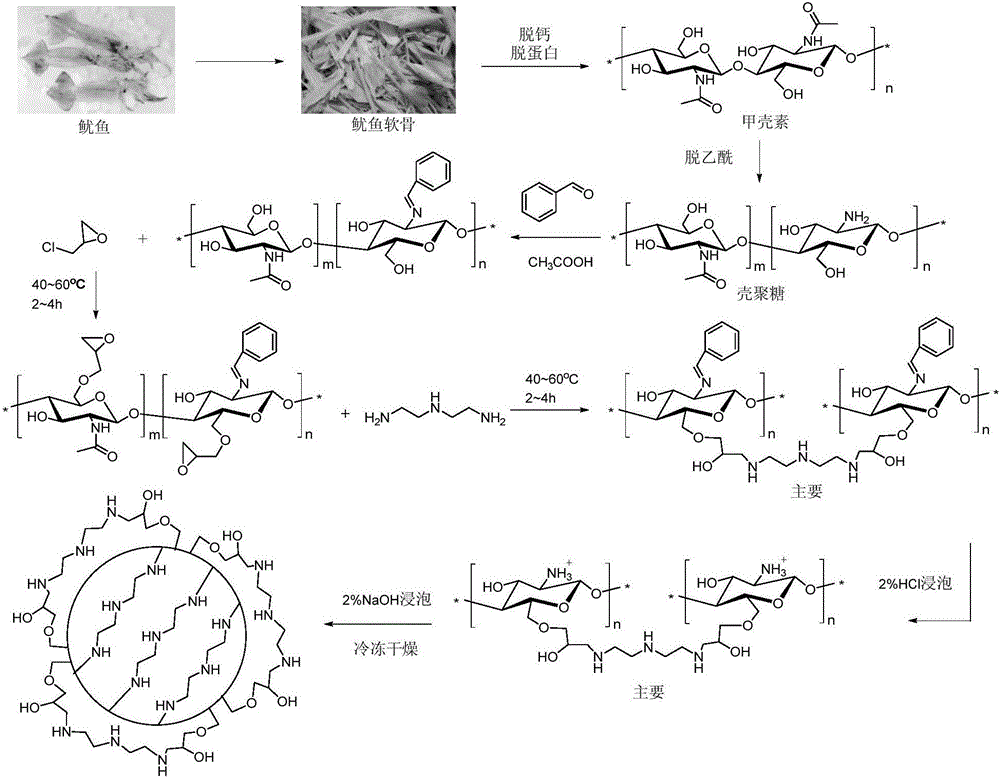

Method used

Image

Examples

Embodiment 1

[0040] 1. Preparation of cross-linked chitosan microspheres

[0041] 1) Preparation of chitosan acetic acid solution: prepare 2% (vt) acetic acid solution with glacial acetic acid, get a certain amount of 2% acetic acid solution to be mixed with 3% (wt) chitosan acetic acid solution and magnetically stir at room temperature to dissolve completely After standing still, obtain uniform light brown viscous solution;

[0042]2) Preparation of oil phase and surfactant: use 3% chitosan acetic acid solution as water phase, liquid paraffin as oil phase, add oil phase: water phase = 3:1 volume ratio; use Span80 as surface active agent, the added volume ratio is 1 / 10 of the water phase;

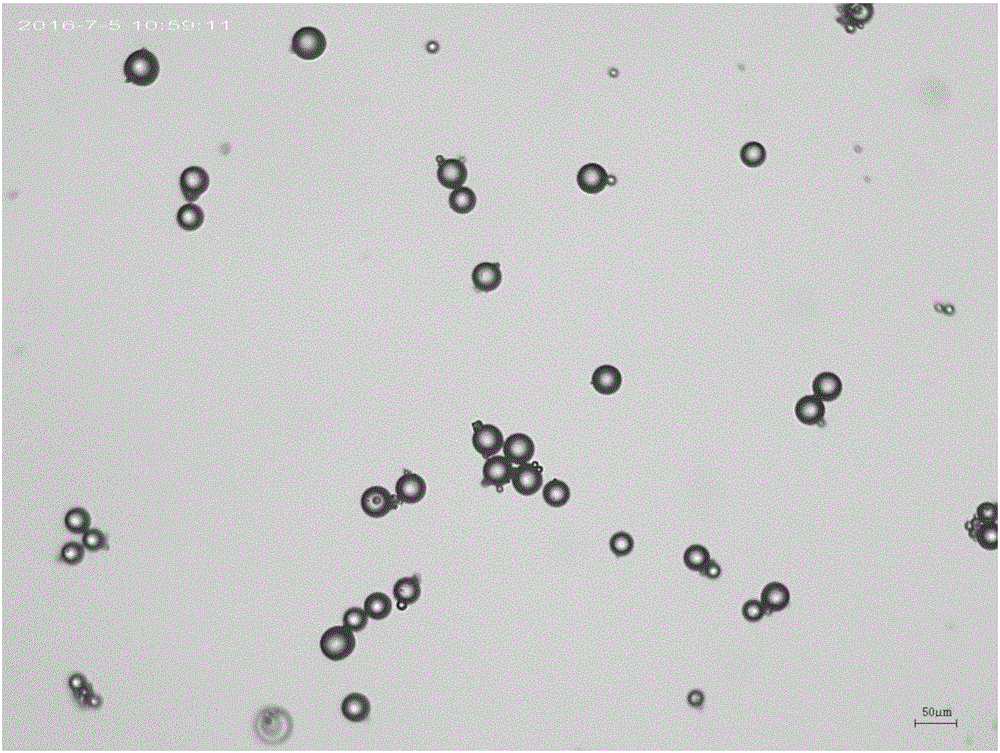

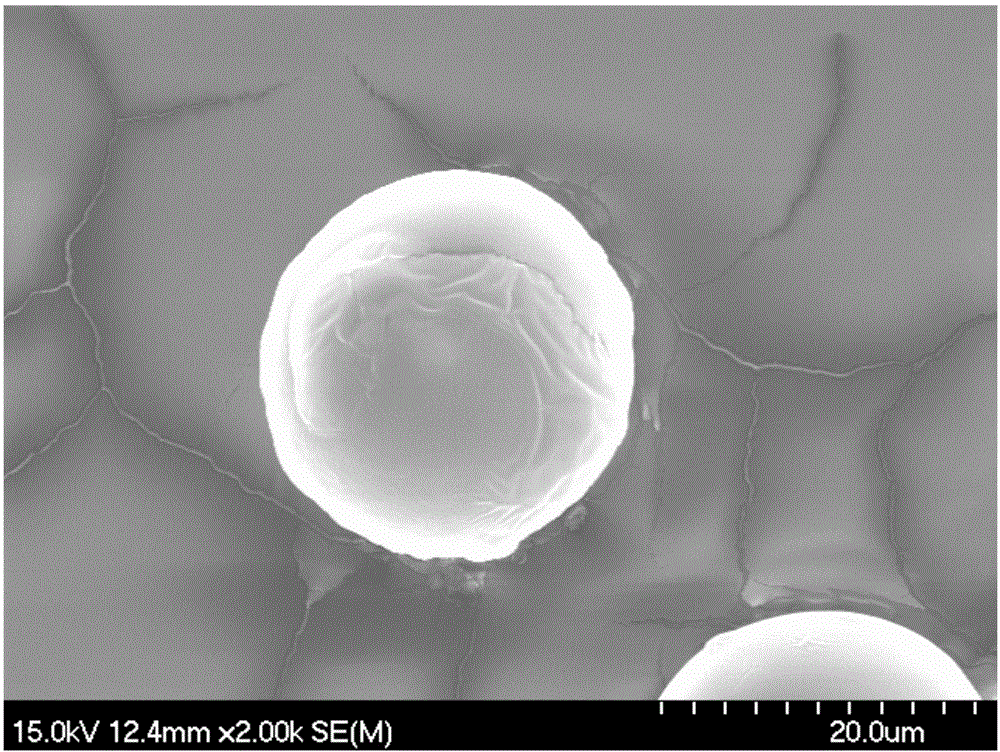

[0043] 3) The preparation process of cross-linked chitosan microspheres: at room temperature, use a syringe to draw 10 mL of 3% chitosan acetic acid solution (chitosan mass is about 0.3 g) in step 1) and add it to the preparation in step 2). In a 250mL flat-bottomed flask with 30mL of liquid paraffin ...

Embodiment 2

[0048] 1. Preparation of cross-linked chitosan microspheres

[0049] 1) Preparation of chitosan acetic acid solution: prepare 2% (vt) acetic acid solution with glacial acetic acid, get a certain amount of 2% acetic acid solution to be mixed with 3% (wt) chitosan acetic acid solution and magnetically stir at room temperature to dissolve completely After standing still, obtain uniform light brown viscous solution;

[0050] 2) Preparation of oil phase and surfactant: use 3% chitosan acetic acid solution as water phase, liquid paraffin as oil phase, add oil phase: water phase = 3:1 volume ratio; use Span80 as surface active agent, the added volume ratio is 1 / 10 of the water phase;

[0051] 3) The preparation process of cross-linked chitosan microspheres: at room temperature, use a syringe to draw 10 mL of 3% chitosan acetic acid solution (chitosan mass is about 0.3 g) in step 1) and add it to the preparation in step 2). In a 250mL flat-bottomed flask with 30mL of liquid paraffin...

Embodiment 3

[0055] 1. Preparation of cross-linked chitosan microspheres

[0056] 1) Preparation of chitosan acetic acid solution: prepare 2% (vt) acetic acid solution with glacial acetic acid, get a certain amount of 2% acetic acid solution to be mixed with 3% (wt) chitosan acetic acid solution and magnetically stir at room temperature to dissolve completely After standing still, obtain uniform light brown viscous solution;

[0057] 2) Preparation of oil phase and surfactant: use 3% chitosan acetic acid solution as water phase, liquid paraffin as oil phase, add oil phase: water phase = 3:1 volume ratio; use Span80 as surface active agent, the added volume ratio is 1 / 10 of the water phase;

[0058] 3) The preparation process of cross-linked chitosan microspheres: draw 10 mL of 3% chitosan acetic acid solution (chitosan mass is about 0.3 g) in step 1) with a syringe at room temperature In a 250mL flat-bottomed flask with 30mL of liquid paraffin and 1mL of Span80, stir at a stirring rate o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com