Petroleum separating device

A separation device and oil technology, applied in the direction of multi-stage serial refining process, etc., can solve the problems of low performance stability, single type of separation, low oil separation precision, etc., achieve powerful functions and improve practical life , the effect of reducing heat damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

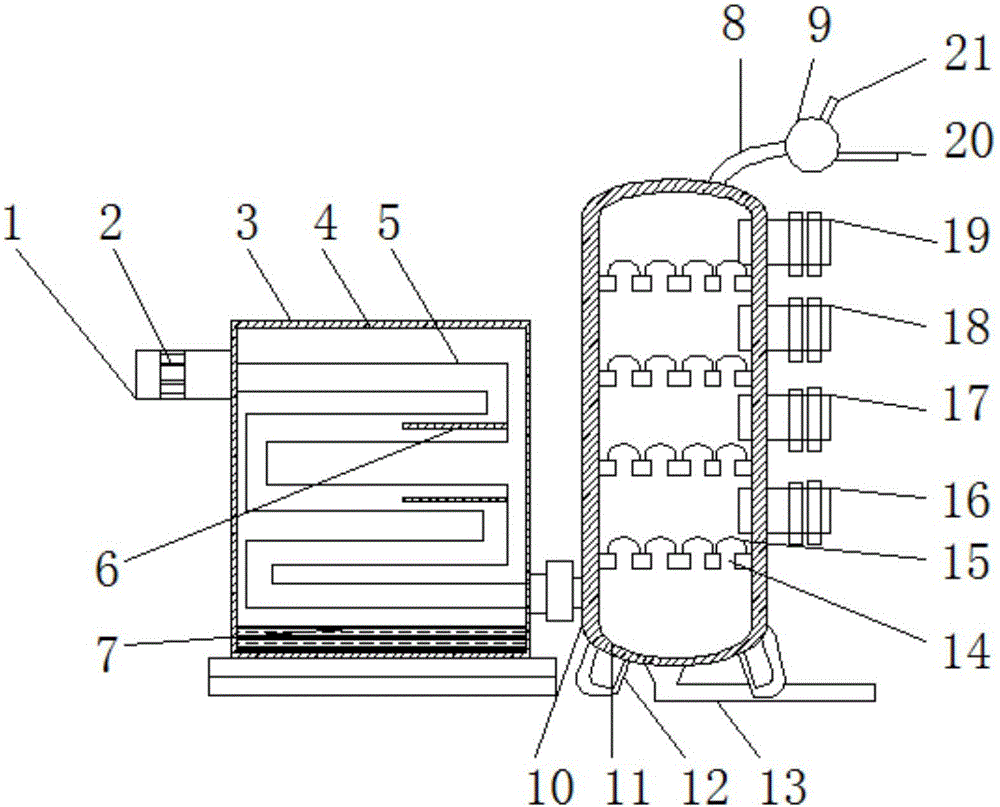

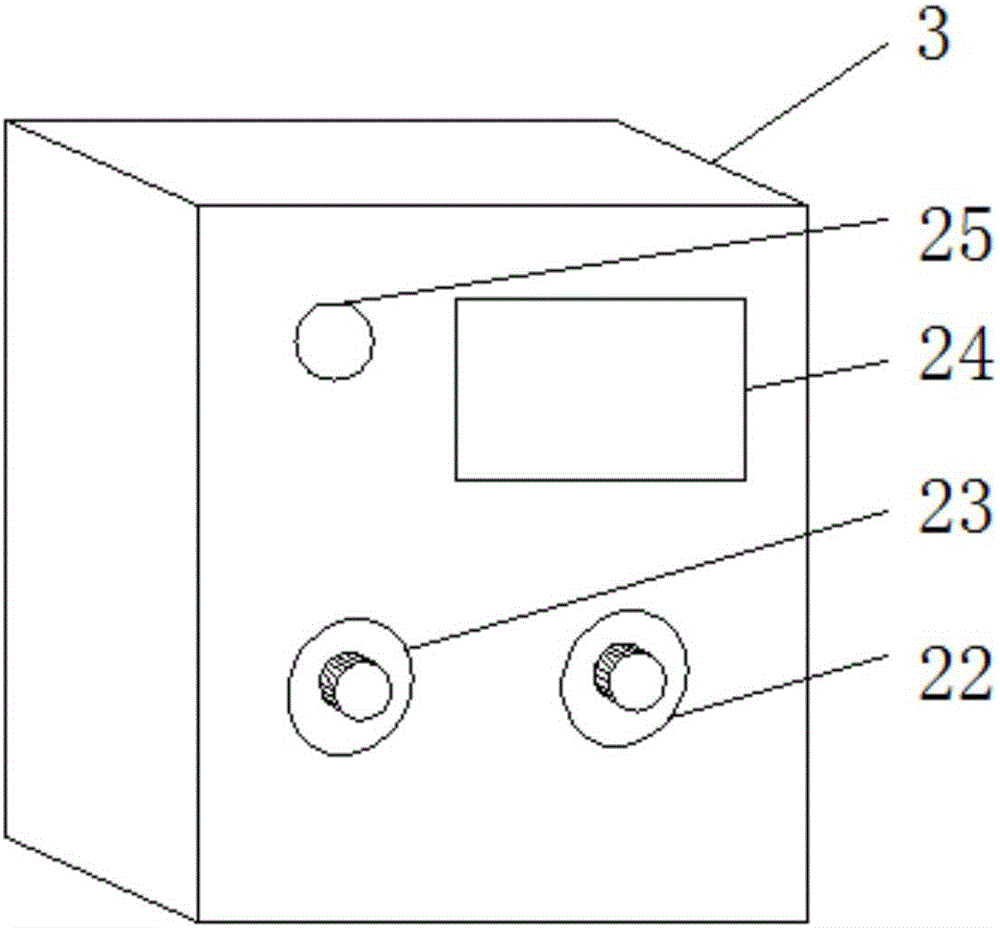

[0016] refer to Figure 1-2 , a kind of petroleum separation device, comprises petroleum heating furnace 3, condensation bottle 9, petroleum fractionation tower 10, and petroleum heating furnace 3 left side is equipped with oil inlet pipe 1, and petroleum heating furnace 3 surface is installed with thermal insulation layer 4, and petroleum heating furnace 3 is equipped with an oil pipe 5 inside, and a temperature sensor 6 is installed inside the oil pipe 5, a petroleum fractionation tower 10 is installed on the right side of the petroleum heating furnace 3, an anti-corrosion layer 11 is installed on the surface of the petroleum fractionation tower 10, and a branch is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com