Shell type heat exchanger, water cooling add-on module, and water cooling system

A heat exchanger and shell technology, used in refrigeration components, heating/cooling equipment, evaporators/condensers, etc., can solve the problems that affect the heat dissipation effect of power batteries, the complex structure of shell heat exchangers, and the inconsistency of thermal fluid velocity in the shell. Equalize the problem, achieve the effect of compact structure, simple and orderly layout, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing of description, the present invention will be further described.

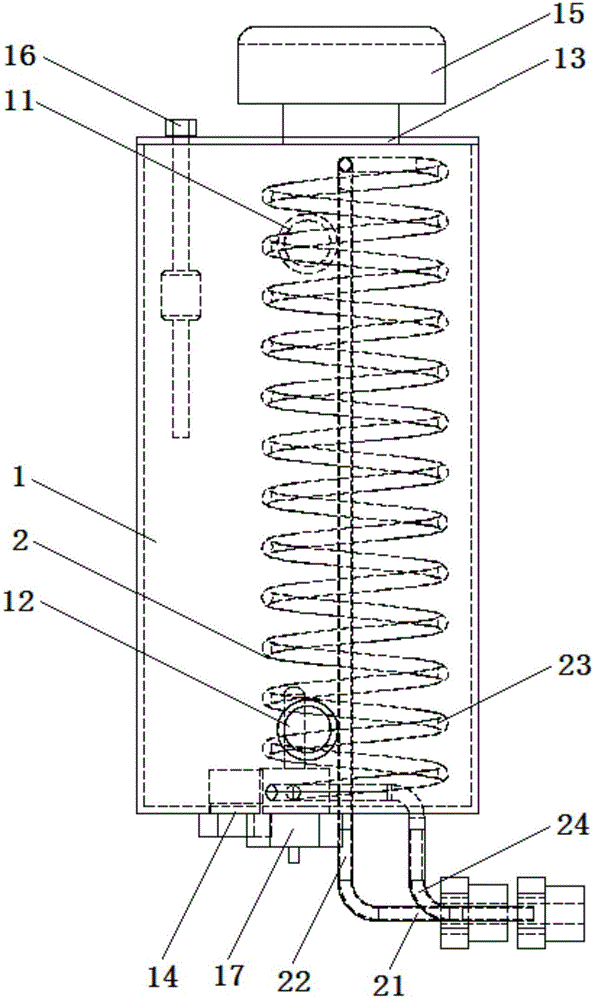

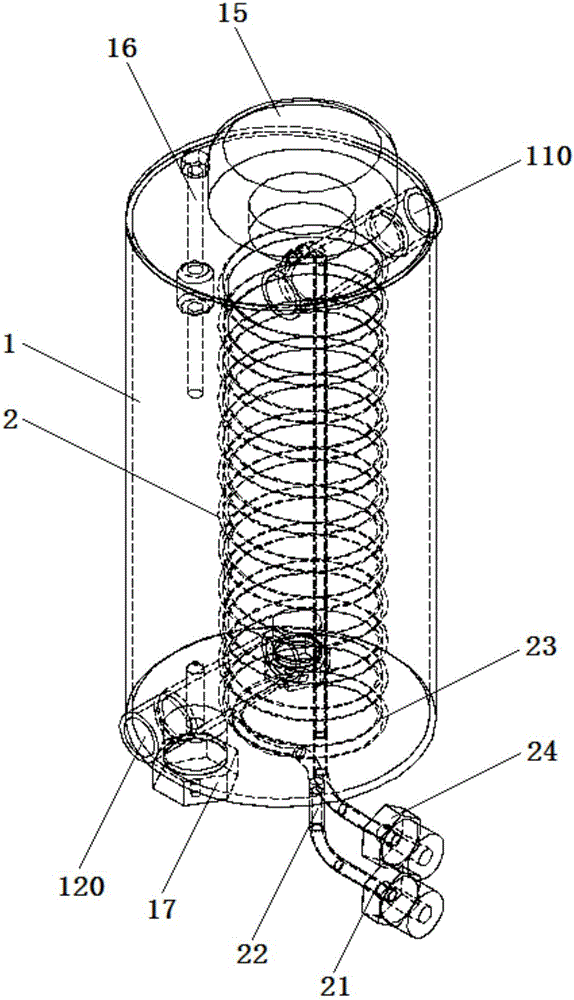

[0031] Such as figure 1 and figure 2 A shell heat exchanger shown includes a vertical shell 1 and a coil evaporator 2 inside the vertical shell 1; the vertical shell 1 and the coil evaporator 2 are made of stainless steel become.

[0032] The top side of the vertical housing 1 is provided with a water inlet 11, the bottom of the side is provided with a water outlet 12, the top surface of the vertical housing 1 is provided with an exhaust port 13, and the bottom surface is provided with a sewage outlet 14. The air port 13 is equipped with an automatic exhaust cover 15; the vertical housing 1 is provided with a liquid level float switch 16, and is provided with a temperature sensor 17, and the temperature sensor 17 is installed on the bottom surface of the vertical housing 1, The sensing probe of the temperature sensor 17 extends from the bottom surface of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap