Bearing test device

A technology of bearing test and test head, applied in the direction of mechanical bearing test, etc., can solve the problem of inapplicability of heat dissipation structure, etc., and achieve the effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

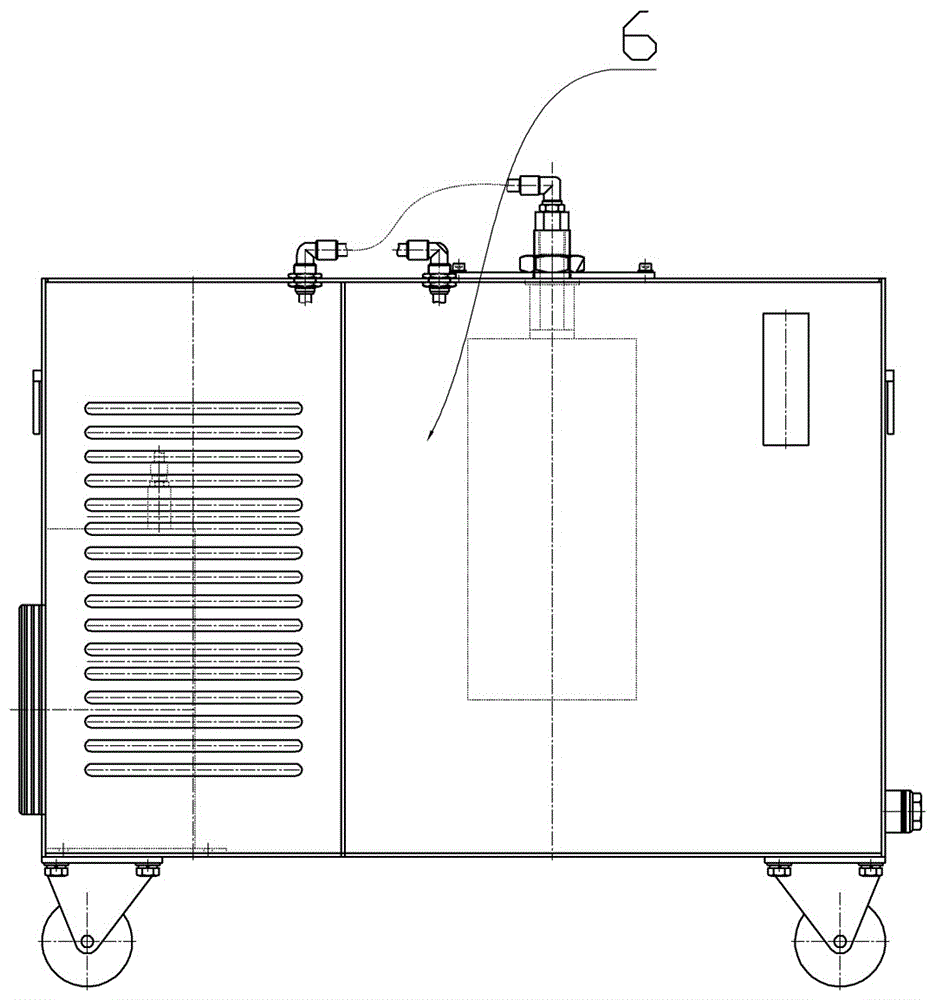

[0043] The specific embodiment 2 of the bearing test device of the present invention, the difference between this embodiment and the above specific embodiment 1 is only that: the first heat dissipation channel is an oil lubrication oil circuit circulation channel, the bearing test device adopts oil lubrication, and the bearing test device uses oil lubrication Oil is medium oil cooling. When using oil lubrication, such as Figure 7 As shown, a plunger 10 is set in the through holes of the left and right bushes to block the through holes of the left and right bushes to reduce the number of inlets and outlets of the oil circuit. road. Keep the first heat dissipation channel unblocked. At this time, the lubricating oil circulates through the first heat dissipation channel. A cooling device can be installed in the oil tank of the lubricating oil to cool the circulating oil circuit to achieve the purpose of heat dissipation.

[0044] In other embodiments of the bearing test device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com