Photovoltaic welding strip production system with high optical utilization ratio and method of photovoltaic welding strip production system

A photovoltaic ribbon and production system technology, applied in liquid cleaning methods, chemical instruments and methods, photovoltaic power generation, etc., can solve problems such as waste of water resources and use costs, achieve increased output power, high work reliability, and improved The effect of energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

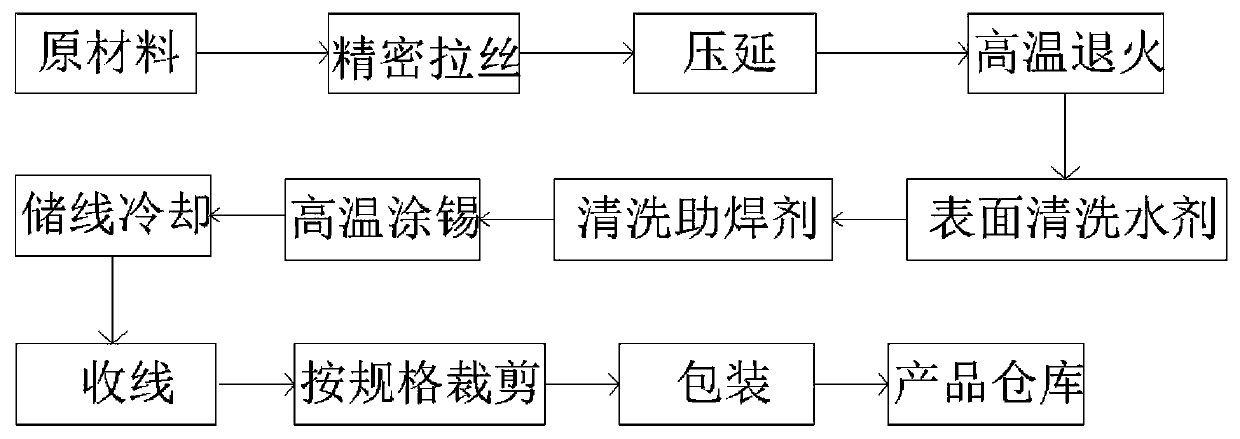

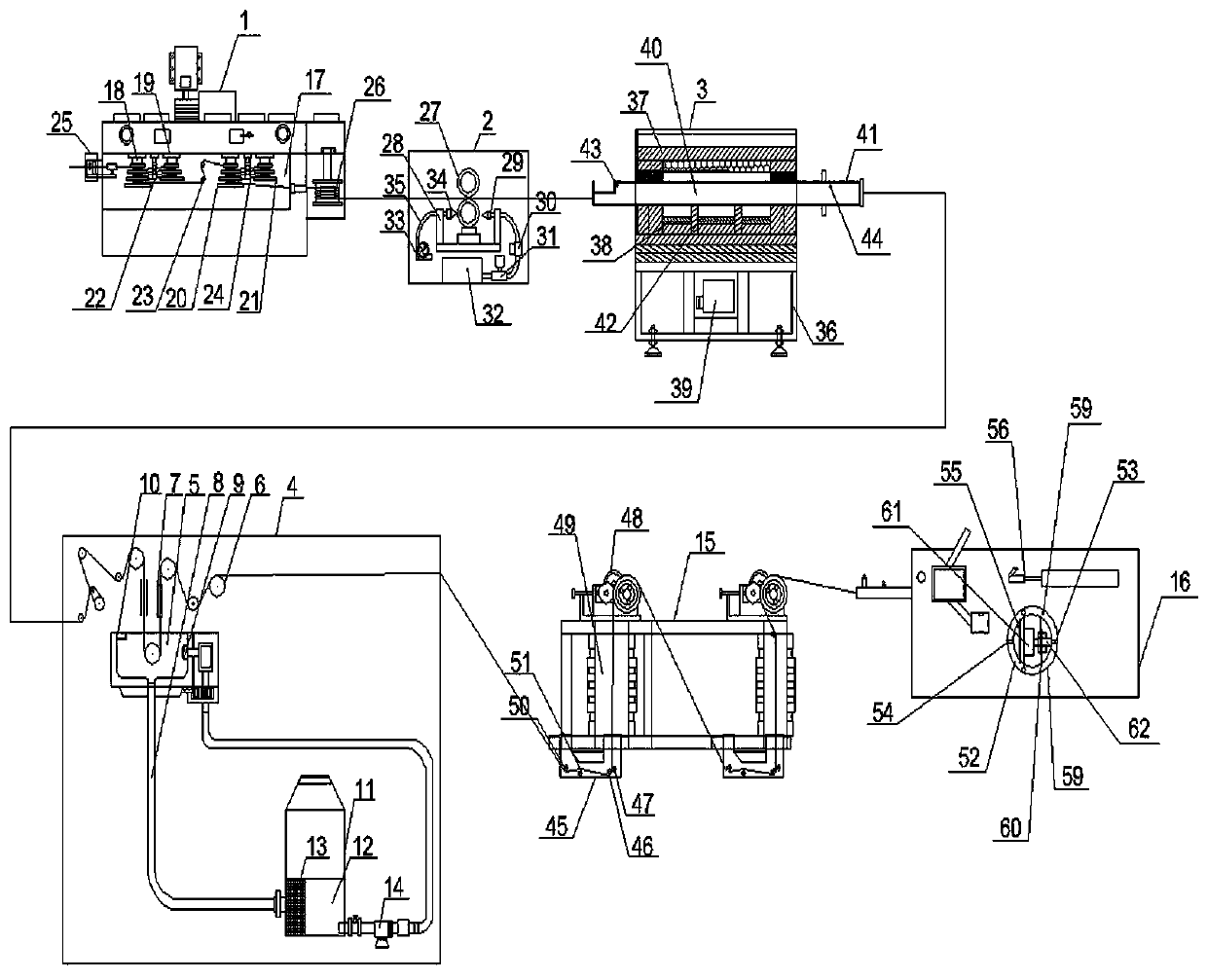

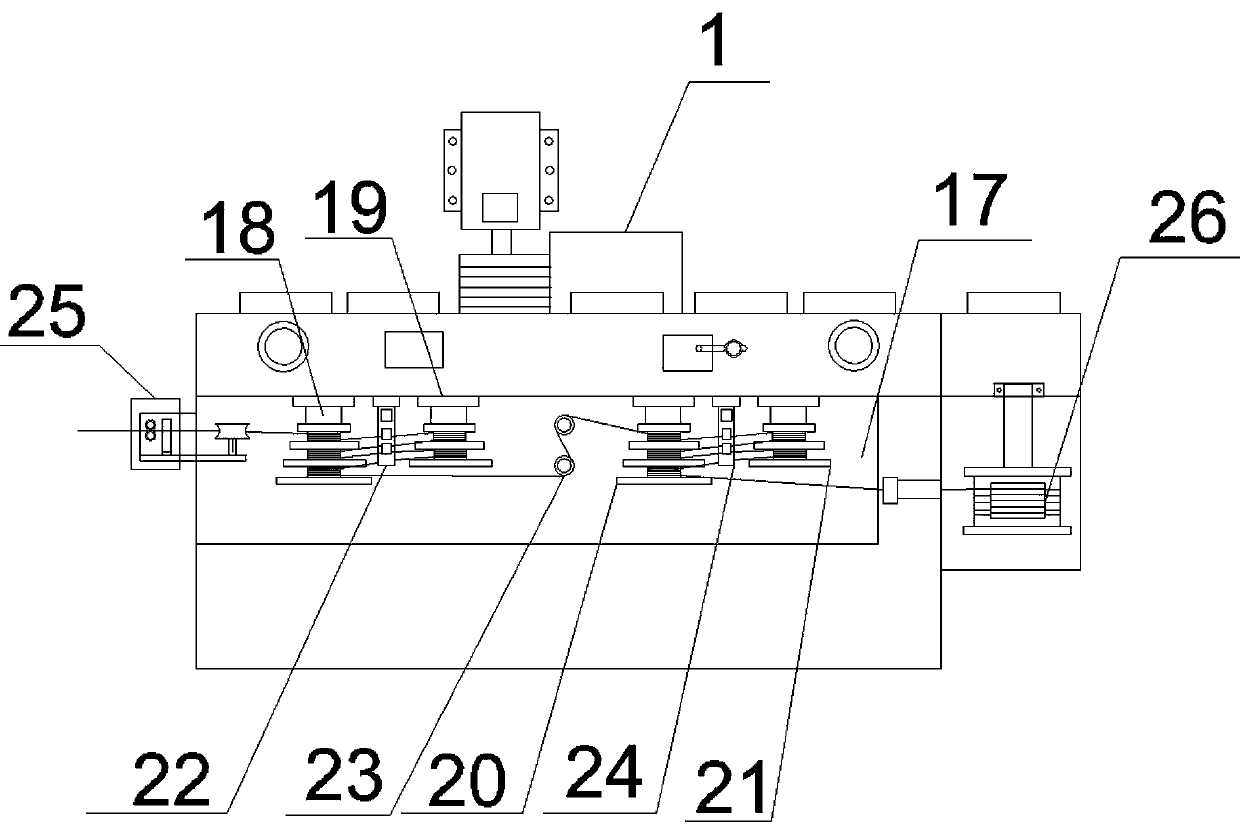

[0041] Embodiment: according to the attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 , attached Image 6 , attached Figure 7 And attached Figure 8 To further illustrate the invention, a photovoltaic ribbon production system with high optical utilization rate in this example includes a wire drawing machine (1) for drawing copper wire raw materials, and the wire drawing machine (1) output wire end is connected with the wire-entry end of the calender (2), the wire-out end of the calender (2) is connected with the feed port of the annealing furnace (3), and the discharge port of the annealing furnace (3) is connected with the The feed end of the cleaning machine (4) is connected, and the cleaning machine (4) includes a cleaning pool (5) for cleaning the copper strip. The left and right sides of the cleaning pool (5) are respectively equipped with A water eliminator (7) for removing water is also provided between the guid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com