Measuring method for thermal contraction of electronic glass for high resolution display

A measurement method and display technology, applied in the direction of material thermal expansion coefficient, etc., can solve the problems of low precision and large measurement error, and achieve the effect of improving precision, high accuracy and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] The invention provides a method for measuring thermal shrinkage rate of electronic glass for high-resolution display, the method comprising the following steps:

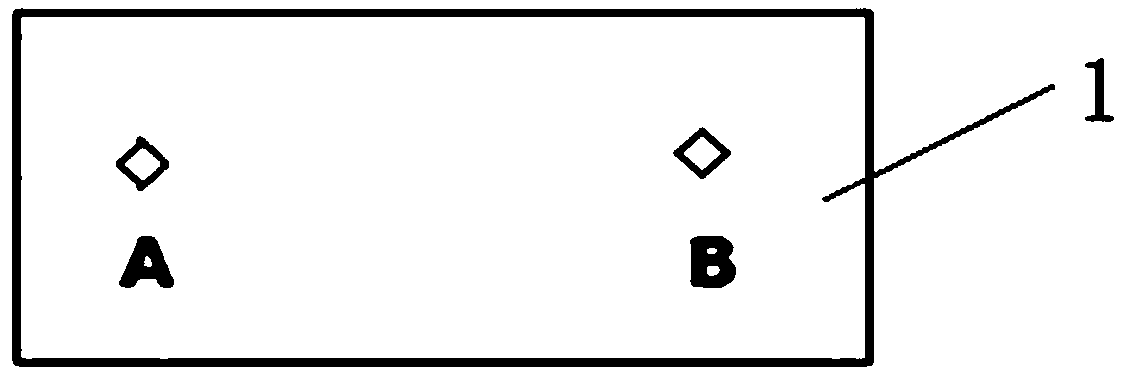

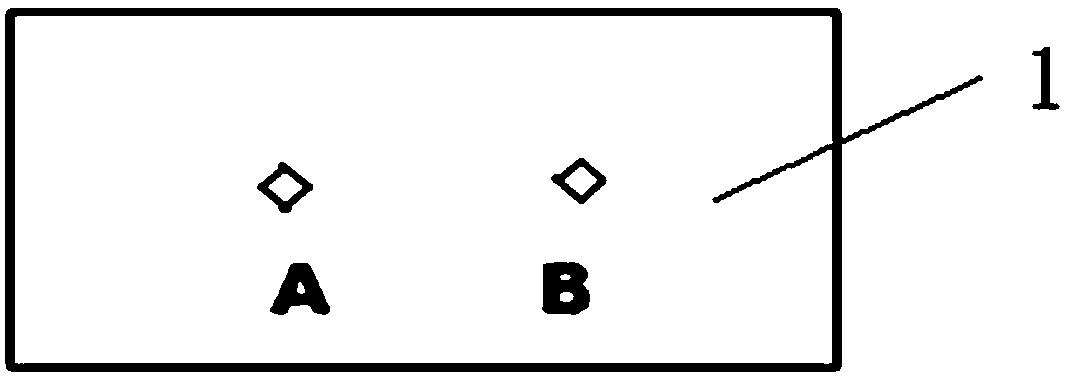

[0041] Step (1): Take the glass sample to be tested, and use a Vickers hardness tester to make two diamond-shaped marks on the two sides of the sample to be tested in the length direction, which are marked as A and B;

[0042] Step (2): Use an optical microscope to measure the distance L0 between A and B;

[0043] Step (3): Put the sample into the grid tray, then put the tray into the small grid space of the heating device, heat the sample to 550°C and 600°C at a heating rate of 5-10°C / min, and keep it warm for 10 After ~120°C, cool down to room temperature at a cooling rate of 10-600°C / min, then take out the tray from the heating device and place it in a constant room temperature environment;

[0044] Step (4): using an optical microscope to measure the distance L between A and B;

[0045] Step (5): Calcula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com