Optical frequency shift suppression method for a serf atomic magnetometer

A technology of atomic magnetic strength and optical frequency shift, which is applied to the size/direction of the magnetic field, the use of magneto-optical equipment for magnetic field measurement, and the measurement of magnetic variables. It can solve the problems of relying on measurement accuracy and achieve high suppression accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

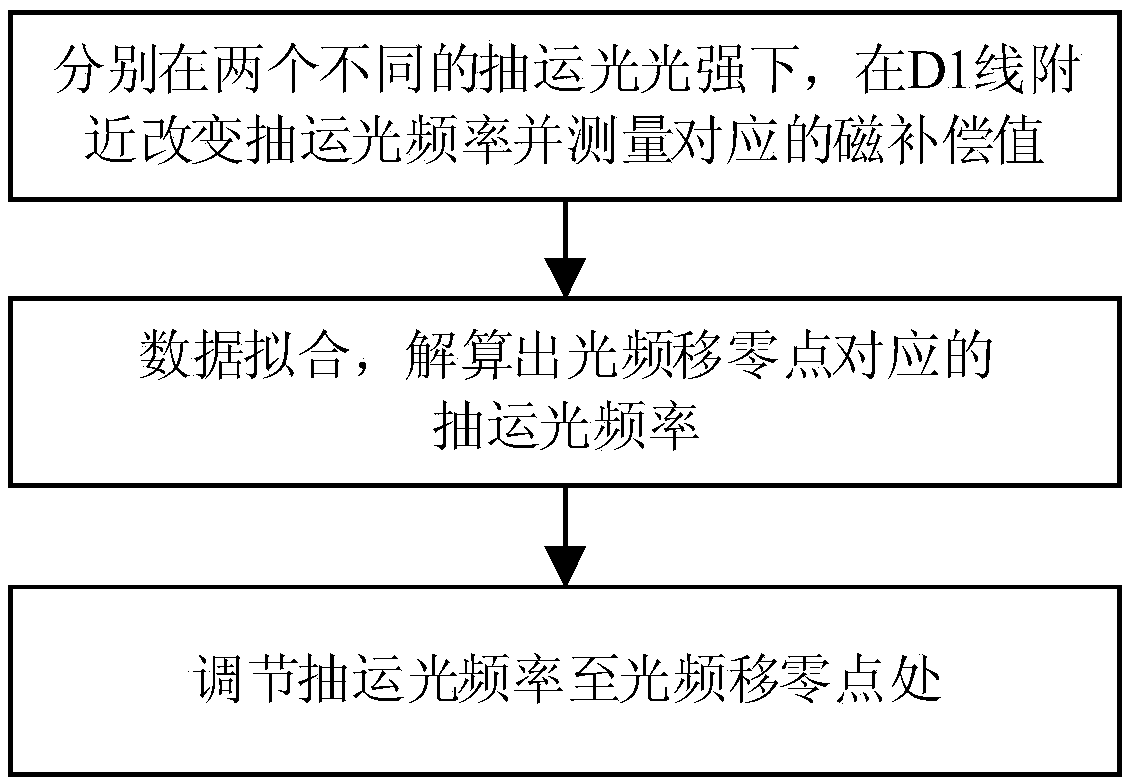

[0019] like figure 1 Shown, the specific implementation steps of the present invention are as follows:

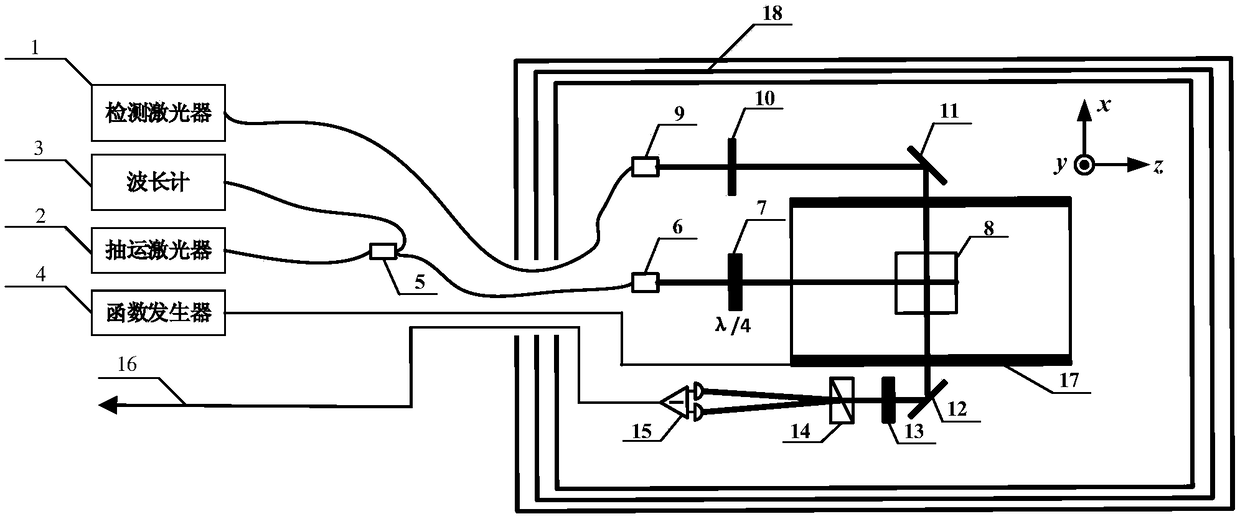

[0020] (1) Realize that the experimental device utilized by the present invention is as figure 2 shown. Wherein the alkali metal gas chamber 8 is installed in the shielding barrel 18 and heated until the alkali metal atomic number density reaches 10 13 ~10 14 piece / cm 3 order of magnitude to ensure that the atom works in the SERF state. Adjust the frequency of the laser light output by the pump laser 2 to the vicinity of the alkali metal atom D1 line. After the output laser light is split by the optical fiber beam splitter 5, one beam enters the wavelength meter 3 for monitoring its frequency, and the other beam passes through the optical fiber The collimator 6 converts it into spatial light, and then passes through the 1 / 4 wave plate 7 to become circularly polarized light to irradiate the alkali metal gas cell 8 to realize the pumping of atoms. The laser output from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com