A kind of preparation method of high-density bimetallic single-atom oxygen reduction catalyst

A single-atom oxygen, bimetallic technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. To achieve the effect of enhanced interaction, excellent electrochemical stability, and enhanced activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

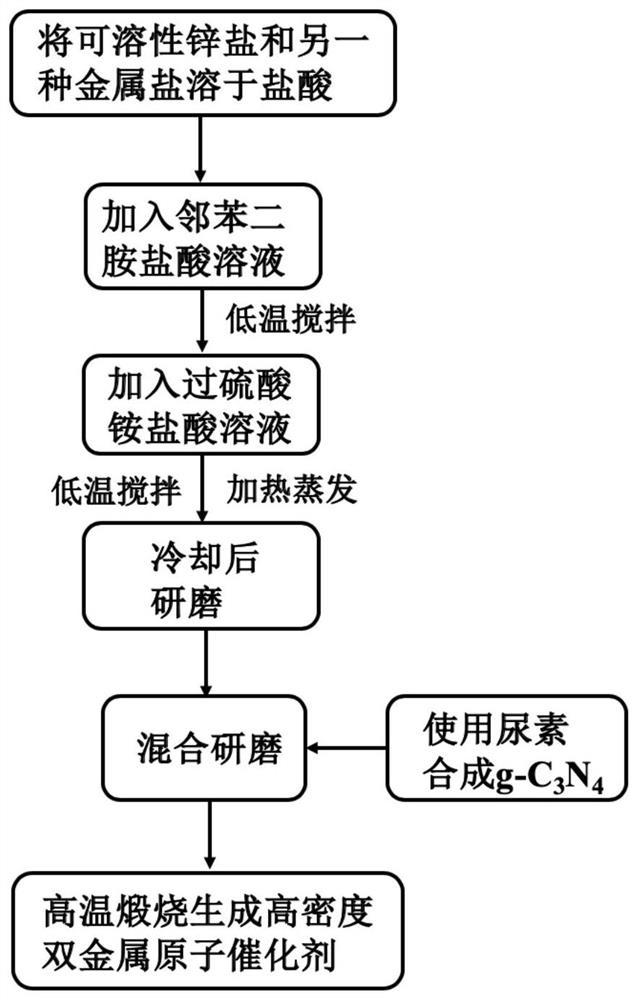

[0037] The present invention provides a high-density bimetallic single-atom oxygen reduction catalyst preparation method, comprising the following steps:

[0038] Step 1: Configure the precursor solution:

[0039] The soluble zinc salt was dissolved in another soluble metal salt in hydrochloric acid to give a first solution; the o-phenylenediamine (OPD) was dissolved in hydrochloric acid to give a second solution, the first solution and the second solution were mixed and stirred at 0 °C for 1 to 2 h to give a third solution; ammonium persulfate was dissolved in hydrochloric acid to give a fourth solution; slowly dissolved in the fourth solution and stirred at 0 ° C for 2 to 3 h, and then stirred at room temperature for 12 to 24 h to give a precursor solution;

[0040] It should be noted that the present invention first prepares a first solution, and then prepares a second solution, the first solution and the second solution are mixed to obtain a third solution, after preparing the...

Embodiment 1

[0054] The present embodiment provides a high-density bimetallic single-atom oxygen reduction catalyst preparation method, comprising the following steps:

[0055] Step 1: Prepare the precursor solution:

[0056] Take 1.487 g of zinc nitrate hexahydrate [Zn(NO3) 2 ·6H 2 O] and 0.291 g cobalt nitrate hexahydrate [Co(NO3) 2 ·6H 2 O] Dissolved in 15 ml of 1M HCl, stirred at room temperature for 30 min to give the first solution. Take 1.5g of o-phenylenediamine (OPD) dissolved in 10ml of 1M HCl and dissolve with sufficient agitation to give a second solution. The resulting second solution was added to the first solution, stirred at 0 °C for 2 h to give the third solution. Take 3 g of ammonium persulfate (NH 4 S 2 O 8 Dissolve in 10 ml of 1 M HCl to give a fourth solution (NH 4 S 2 O 8 Solution), then add the fourth solution to the third solution, stir at 0 °C for 2h and then stir at room temperature for 24h to obtain the precursor solution.

[0057] Step 2: Prepare precursor powder:

...

Embodiment 2

[0068] The present embodiment provides a high-density bimetallic single-atom oxygen reduction catalyst preparation method, comprising the following steps:

[0069] Step 1: Prepare the precursor solution:

[0070] 1.487 g zinc nitrate hexahydrate [Zn(NO3) 2 ·6H 2O] Dissolved in 15 ml of 1M HCl, stirred at room temperature for 30min; 1.5 g of o-phenylenediamine (OPD) dissolved in 10 ml of 1M HCl, well stirred to dissolve; the resulting OPD solution was added to the solution of 1, stirred at 0 °C for 2 h; take 3 g of ammonium persulfate (NH 4 S 2 O 8 Dissolve in 10 ml of 1 M HCl, and then obtain the NH 4 S 2 O 8 The solution is added to the solution of 3 and stirred at 0 °C for 2 h. After stirring at room temperature for 24 h, the precursor solution was obtained.

[0071] Step 2: Prepare precursor powder:

[0072] Transfer the precursor solution to a muffle furnace, heat at 160 °C for 4 h, then cool to room temperature, grind to obtain the precursor powder;

[0073] Step 3: Take 10g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com