A kind of in-based organic framework-graphene oxide composite material and its preparation method and application

An organic framework and composite material technology, applied in chemical instruments and methods, other chemical processes, adsorption water/sewage treatment, etc., can solve problems such as poor adsorption efficiency, and achieve excellent adsorption performance and high adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

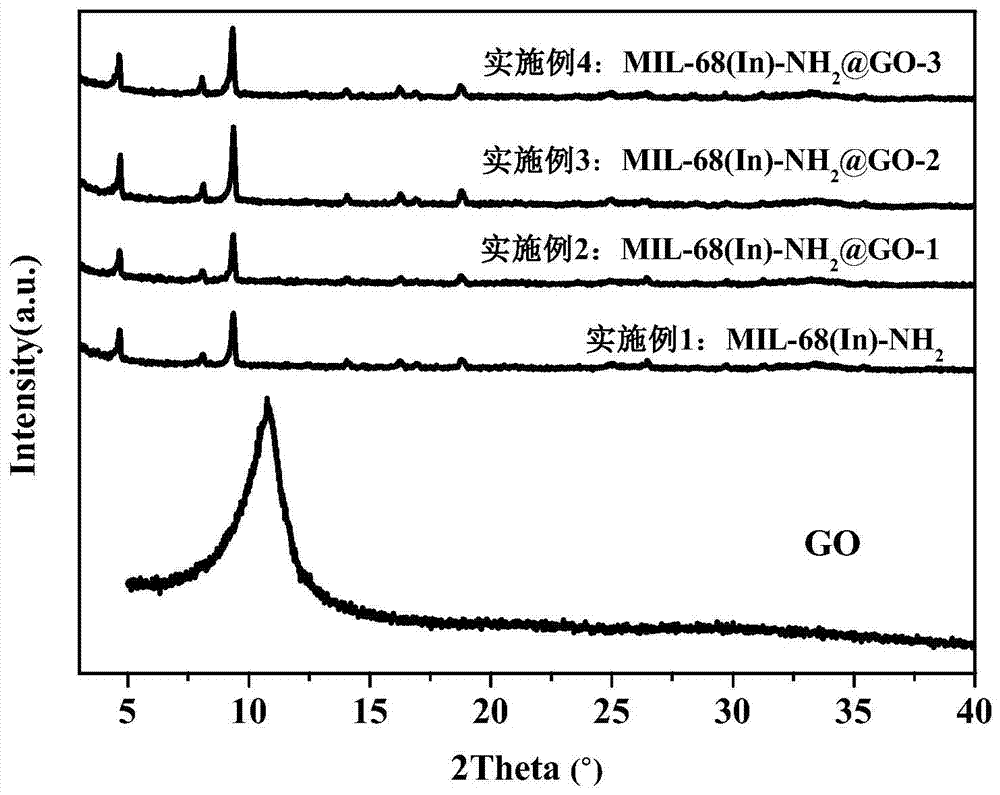

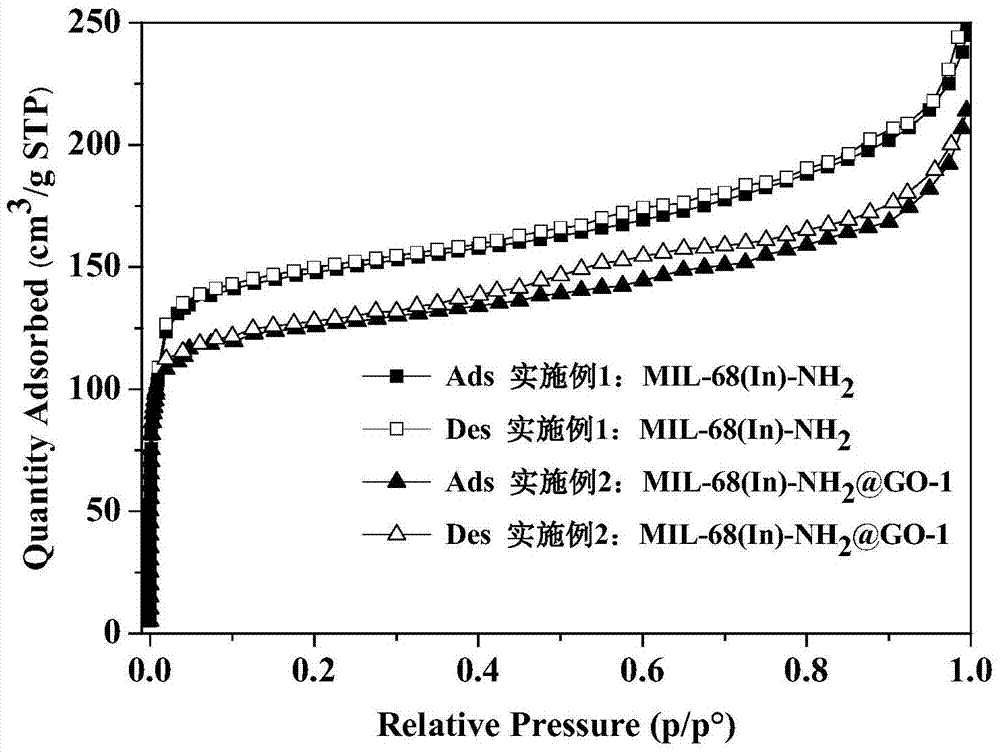

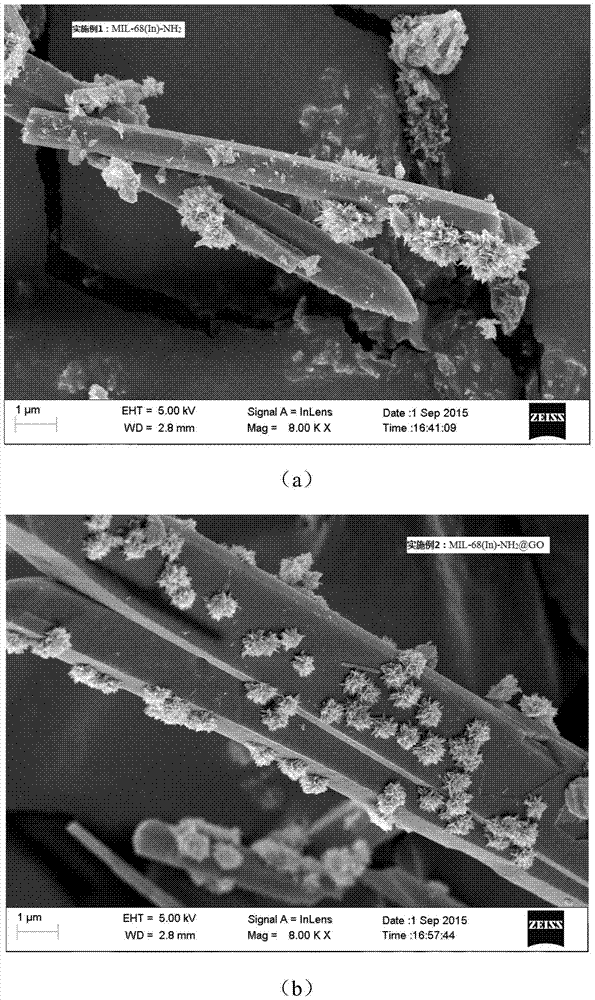

[0028] Embodiment 1: comparative example

[0029] Dissolve 1.49g of indium nitrate and 0.230g of 2-aminoterephthalic acid in 12.4mL of N,N'-dimethylformamide, stir evenly and ultrasonically treat the obtained reaction solution from room temperature at a rate of 10°C / h. to 150°C, keep the temperature constant for 5h, and cool down to room temperature naturally. The product after suction filtration was rinsed with N,N′-dimethylformamide for 3 times, soaked in methanol for 3 days, and passed through a tube furnace in N 2 Calcined at 200°C for 5 hours in the atmosphere, activated at 150°C for 12 hours under vacuum, and marked the sample as MIL-68(In)-NH 2 .

Embodiment 2

[0030] Embodiment 2: Preparation of In-based organic framework-graphene oxide composite material

[0031] 0.0965g graphene oxide powder was dispersed in 11.0mLN, N'-dimethylformamide and ultrasonically treated to obtain a dispersion of graphene oxide; 1.148g indium nitrate and 0.230g 2-aminoterephthalic acid were added to In the above graphene oxide dispersion liquid, stir evenly and ultrasonically treat the obtained reaction liquid from room temperature to 160 °C at a rate of 5 °C / h, keep the temperature constant for 6 hours, and cool naturally to room temperature. The product after suction filtration was rinsed with N,N′-dimethylformamide for 3 times, soaked in methanol for 3 days, and passed through a tube furnace in N 2 Calcined at 180°C for 5 hours in the atmosphere, activated at 130°C for 12 hours under vacuum, and marked the sample as MIL-68(In)-NH 2 @GO-1.

Embodiment 3

[0032] Embodiment 3: Preparation of In-based organic framework-graphene oxide composite material

[0033] 0.0722g of graphene oxide powder was dispersed in 10.1mLN, N'-dimethylformamide and ultrasonically treated to obtain a dispersion of graphene oxide; 1.207g of indium nitrate and 0.237g of 2-aminoterephthalic acid were added to In the above graphene oxide dispersion liquid, uniformly stirred and ultrasonically treated, the obtained reaction liquid was raised from room temperature to 170 °C at a rate of 8 °C / h, kept at a constant temperature for 5 hours, and then naturally cooled to room temperature. The product after suction filtration was rinsed with N,N′-dimethylformamide for 3 times, soaked in methanol for 3 days, and passed through a tube furnace in N 2 Calcined at 150°C for 5 hours in the atmosphere, activated at 100°C for 12 hours under vacuum, and marked the sample as MIL-68(In)-NH 2 @GO-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com