Sectional type high-power high-frequency and high-voltage transformer and sectional winding method thereof

A high-frequency, high-voltage, transformer technology, applied in the direction of inductance/transformer/magnet manufacturing, transformer/inductor coil/winding/connection, fixed transformer or mutual inductance, etc., can solve the problems of increased leakage inductance and volume increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

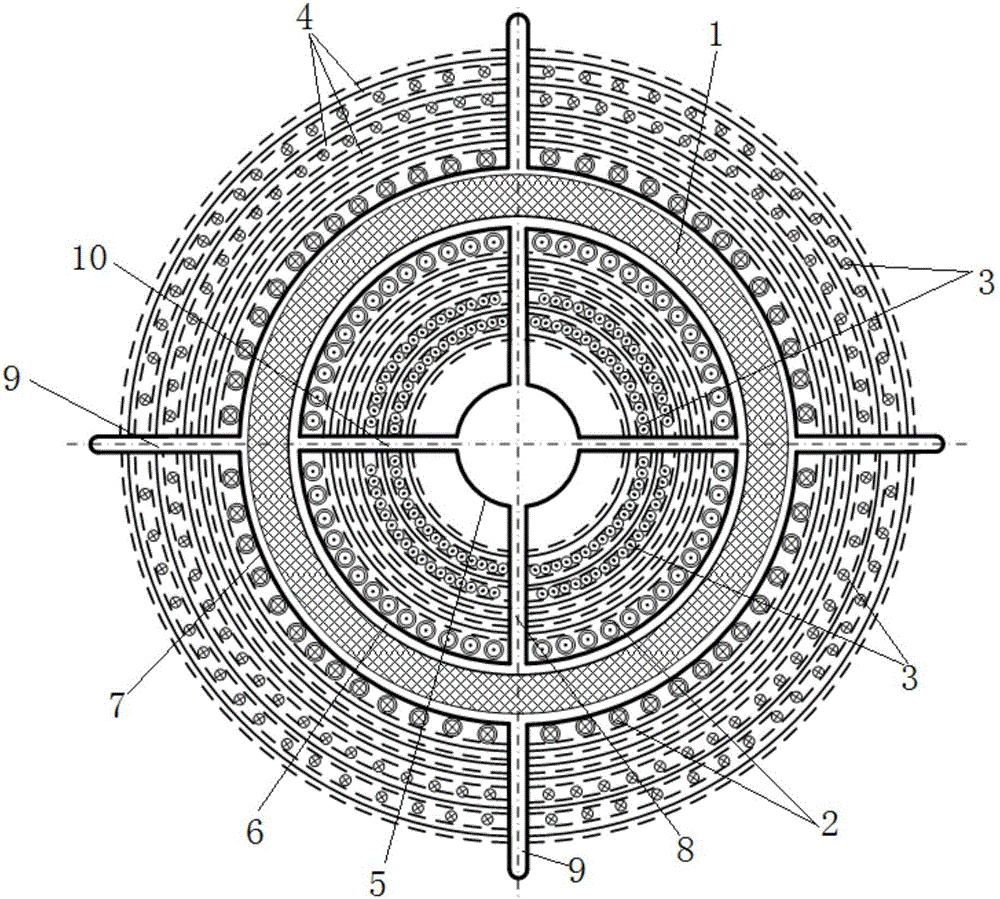

[0137] It is determined that the structure of the high-frequency high-voltage transformer core 1 is a tape-wound toroidal core; the number of turns of the primary winding 2 is 9 turns, and the number of strands is 190; the number of turns of the secondary winding 3 is 120 turns, the number of strands is 12 strands, and the wire is a wire Enameled wire with a diameter of 0.63mm and a withstand voltage of 1.3kV; the insulation index between the layers of the primary winding 2 is 20kV, and the insulating paper used is white composite insulating paper with a withstand voltage of 6.0kV; the insulation between the primary winding 2 and the secondary winding 3 The indicator is 36kV, and the insulating paper used is white composite insulating paper with a withstand voltage of 6.0kV. The interlayer insulation index of the secondary winding 3 is 20kV, and the insulating paper used is white composite insulating paper with a withstand voltage of 6.0kV. The outside of the secondary winding 3...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap