Detachable cable protection tube structure

A technology of cable protection tube and semi-circular tube, which is applied to the installation of cables, cables in ground conduits, and cables in underground pipelines, etc., which can solve the problem that the service life of cable protection tubes is not as good as that of cables, and the personal safety of power lines Hidden dangers, damage to the cable head and the cable itself, etc., to achieve the effect of shortening the maintenance time of power outages, improving the reliability of power supply, and reducing direct economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

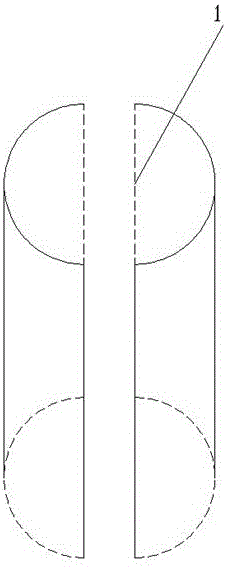

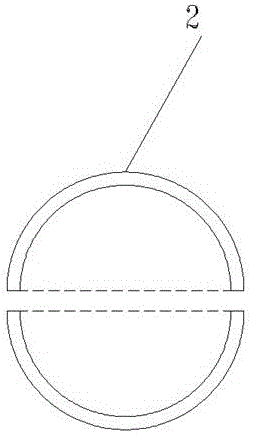

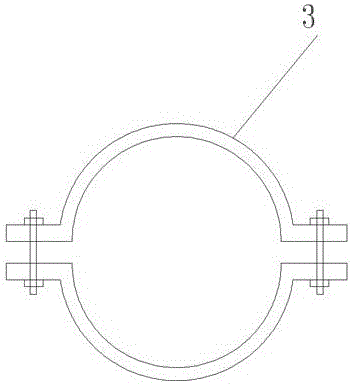

[0020] The embodiment of the present invention: a detachable cable protection tube structure, as shown in the drawings, includes a cable protection tube body 1, the cable protection tube body 1 is surrounded by two semicircular tubes 2 with a semicircular cross section. At least three hoops 3 are evenly arranged around the protective tube body 1.

[0021] A groove 4 is provided on the left side of the semicircular tube 2 and a transition surface 5 is formed between the groove 4 and the left side of the semicircular tube 2, and a boss 6 is provided on the side of the semicircular tube 2 and the boss 6 and The groove 4 on the corresponding semicircular tube 2 is matched, and a layer of elastic plastic layer 7 is arranged on the circumferential surface of the groove 4 and the boss 6. The groove 4 is a cone structure with a small inside and a large outside. The structure of the table 6 is consistent with the structure of the groove 4 and is a transitional or interference fit. At leas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com