Solar cell sorting method and system based on machine vision

A technology of solar cells and machine vision, applied in the field of solar photovoltaics, can solve the problems of unable to sort out cells and detect solar cells, and achieve the effects of ensuring accuracy, reducing labor costs, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

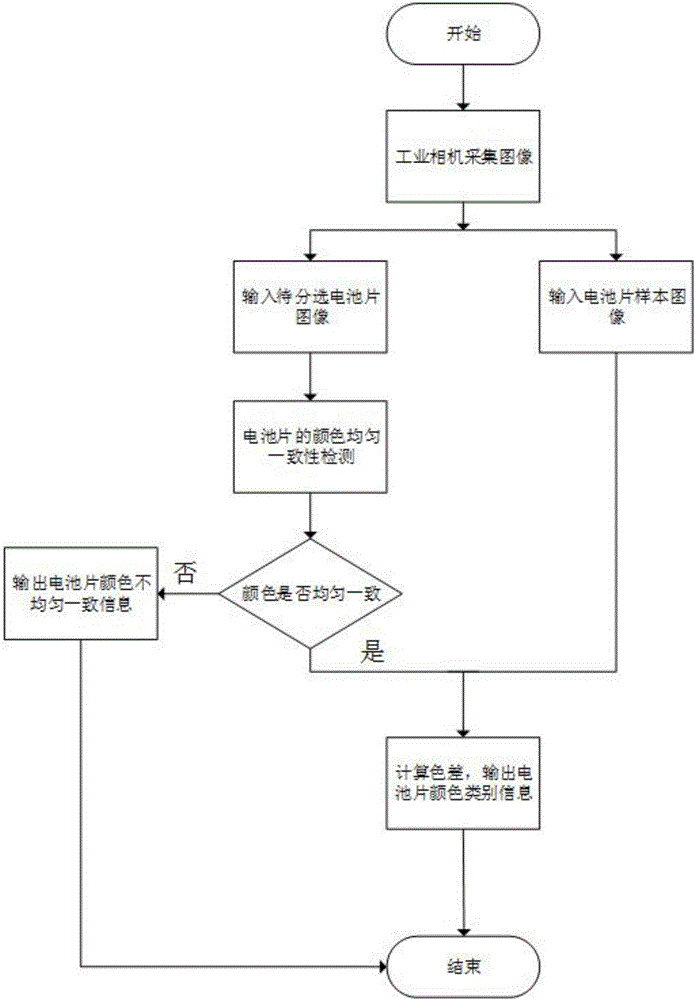

[0035] Embodiment 1: as figure 1 As shown, a sorting method for solar cells based on machine vision includes:

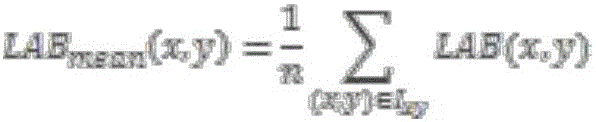

[0036] Step 1: Cell color difference detection initialization operation and collect the image of the cell to be sorted, and convert the collected image into LAB format, wherein the image in LAB mode has more colors and has better results; the initialization operation includes standard sheet collection , use industrial cameras to collect images of various color standard sheets of cells; image conversion, convert the images into LAB format; data calculation and storage, calculate and store the average value of LAB three-component images of various color standard sheets.

[0037] The color image is obtained by the imaging system, and the image is converted into the LAB color space. The L component in the LAB color space is used to represent the brightness of the pixel. The value range is [0,100], which means from pure black to pure white; A means from red to The range ...

Embodiment 2

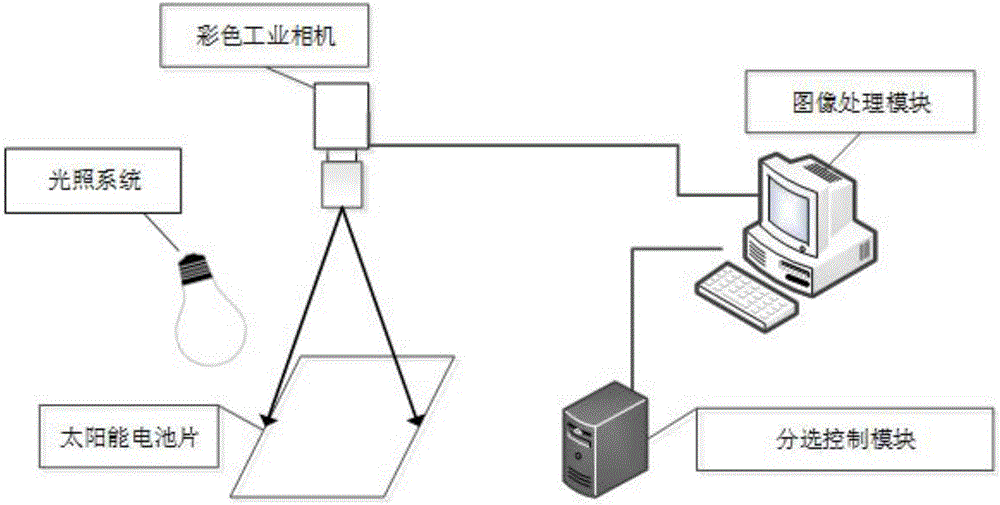

[0056] Embodiment 2: as figure 2 As shown, a machine vision-based solar cell sorting system includes:

[0057] Image acquisition module: used to collect digital images of solar cell labels and solar cells to be sorted;

[0058] Image processing module: used to analyze and process the color difference of the digital image collected by the image acquisition module; detect whether the color in the solar cell is uniform, and then calculate the color difference value between the cell with uniform color and the cell standard sheet, and judge The color category of the cell;

[0059] Sorting control module: receive the color data obtained by the image processing module, and control the delivery module to sort the solar cells;

[0060] Transport module: receive the signal from the sorting control module, and control the transport device to transport solar cells;

[0061] The signals among the image acquisition module, the image processing module, the sorting control module and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com