Forming method for automobile torsion beam

A forming method and technology of torsion beams, applied in vehicle parts, transportation and packaging, etc., can solve the problems of high equipment requirements, high cost, complicated process, etc., and achieve the effect of guaranteeing sealing effect and mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

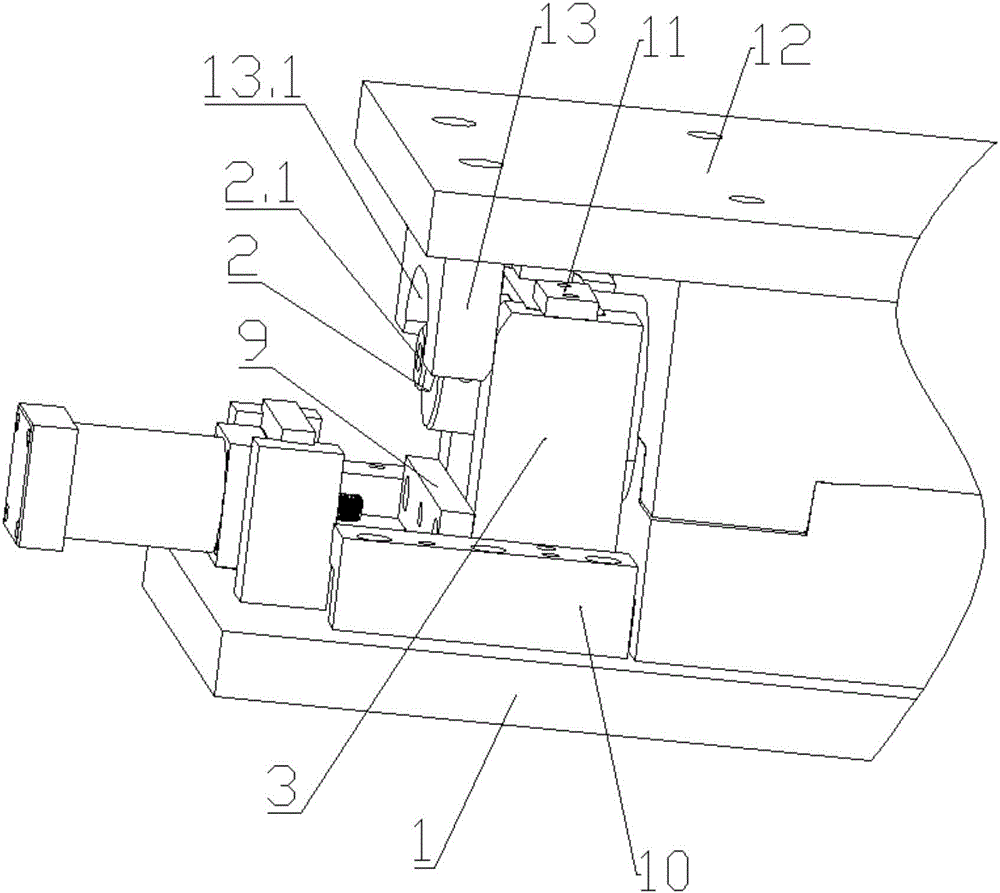

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0028] A kind of molding method of automobile torsion beam of the present invention, preparation step comprises:

[0029] (1) Open the forming mold to a certain height and place the tubular blank in the mold;

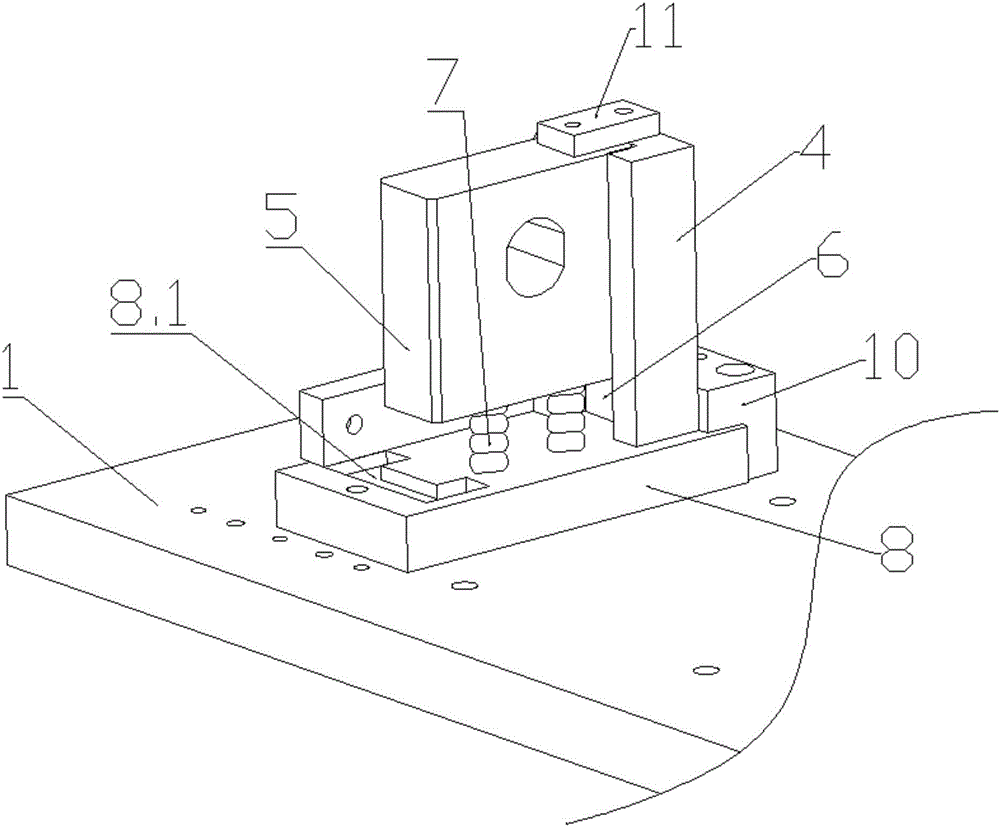

[0030] As shown in the drawings: the forming mold includes a lower mold base 1, a plug 2 and an upper template 12, and the end of the lower mold base 1 is symmetrically provided with a first stopper 3 and a second stopper 4;

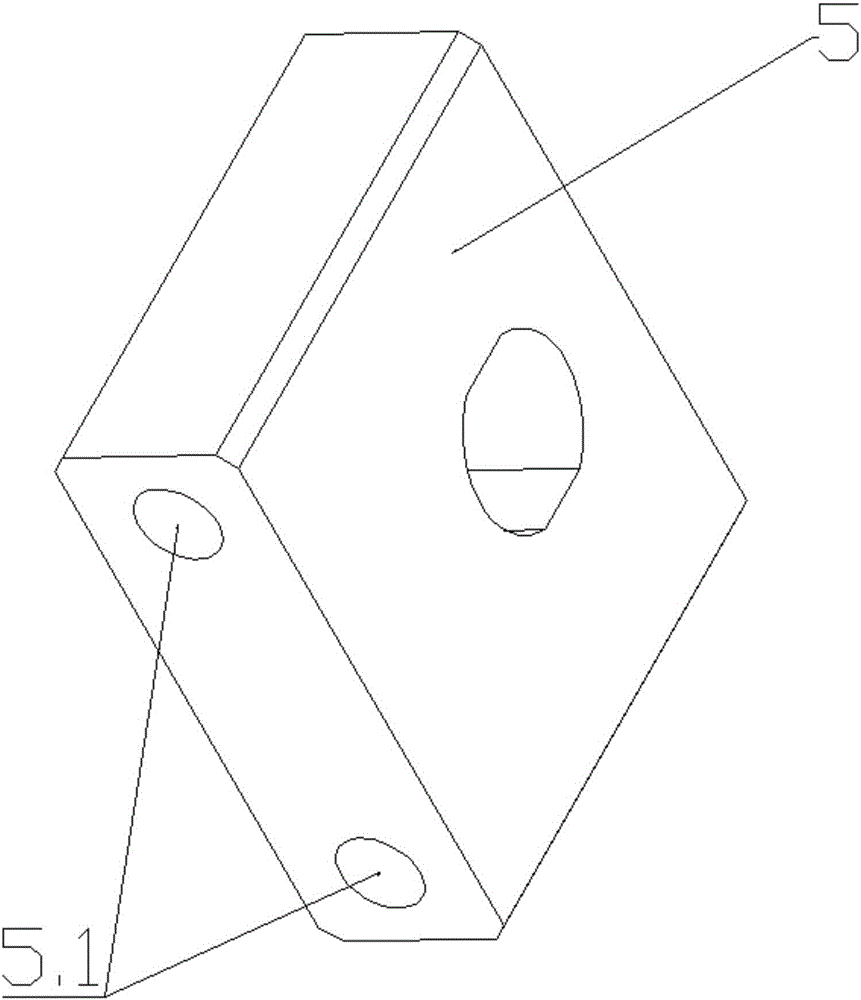

[0031] A slider 5 is arranged between the first block 3 and the second block 4, and the plug 2 is installed in the slider 5. In this embodiment, the plug 2 is installed in the slider 5 Finally, the sealed end and the exposed end of the plug 2 extend out of the slider 5 respectively, and the exposed end of the slider 5 is provided with a connection hole 2.1 to realize the connection with the driving cylinder piston ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com