Turning inner brace fixture for end opening of cylinder

A port and turning technology, which is applied to turning equipment, metal processing equipment, workpieces, etc., can solve the problem that the clamping accuracy cannot meet the process requirements, and achieve the effects of reducing manual operation intensity, uniform force, and small tooling error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

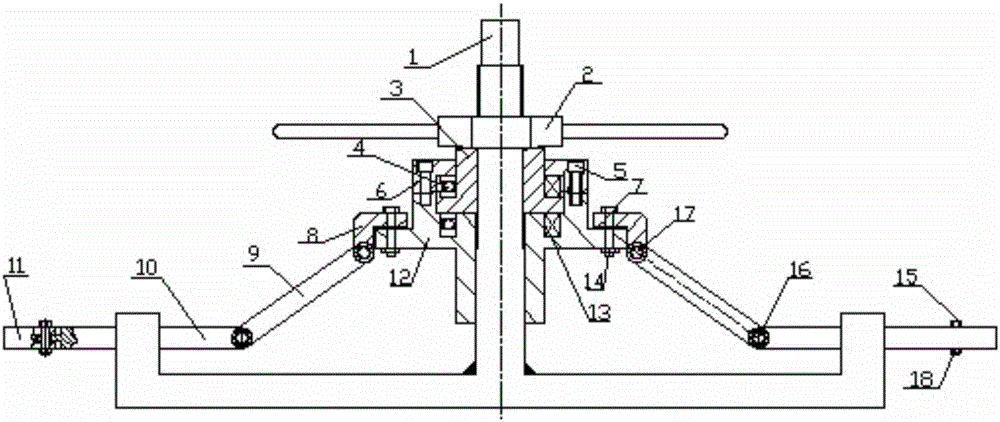

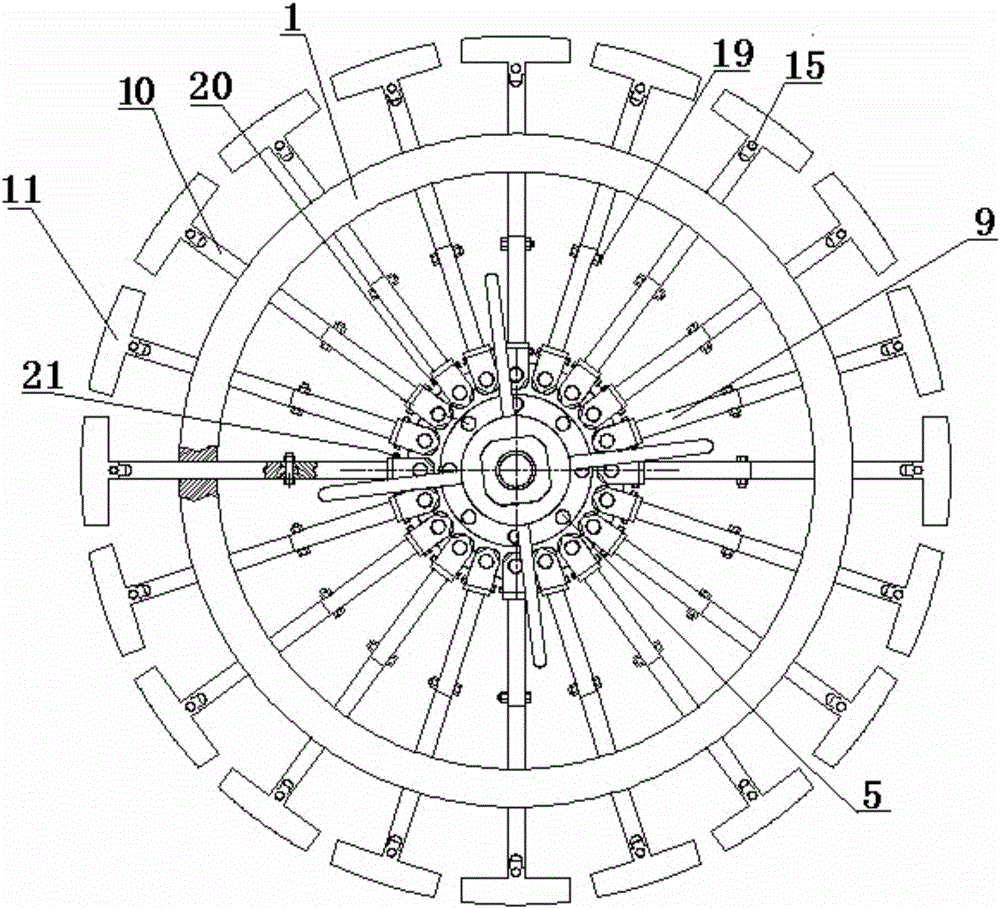

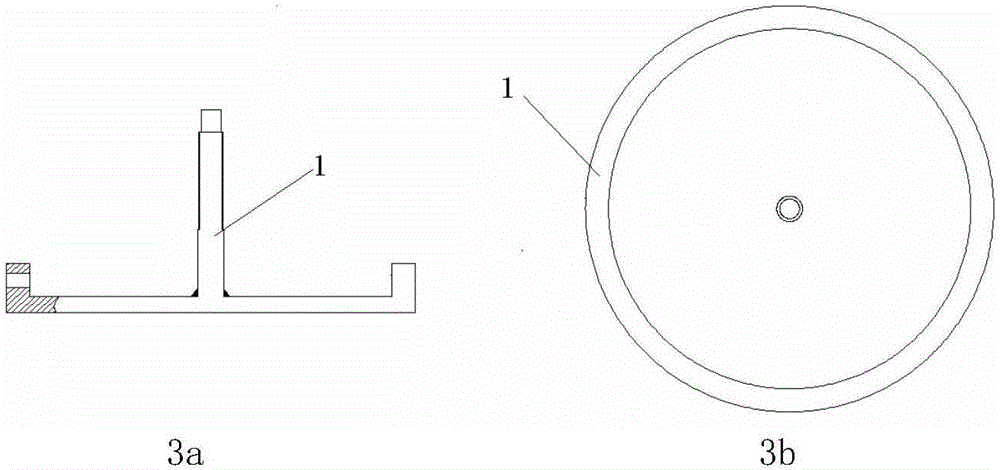

[0034] This embodiment is an internal support tooling used for turning the welding groove of the port of a thin-walled cylinder with a diameter of φ750×δ3×1450. The part is a thin-walled cylindrical part. The cylinder adopts spinning forming technology. The inner diameter of the cylinder is Ф744, the wall thickness of the cylinder is 3mm, and the total length of the cylinder is 1450mm. The design drawings require that the welding groove be machined at the end of the cylinder, the slope of the welding groove is required to be 45°, and the size of the blunt side of the groove is

[0035] The turning inner brace for the welding groove of the port of the thin-walled cylinder includes a mandrel disk 1 , a large nut 3 , a transmission rod 9 , a push rod 10 , a top block 11 and a sliding sleeve 7 . Wherein: the large nut 3 is set on the external threaded surface of the upper end of the mandrel disc, the sliding sleeve 7 is set on the outer circular surface of the lower end of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com