System for polishing and wire drawing of panel and oil tank of range hood

A technology for grinding wire drawing and range hood, applied in the direction of grinder, manipulator, abrasive belt grinder, etc., can solve the problems of low production efficiency, poor working environment, high labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

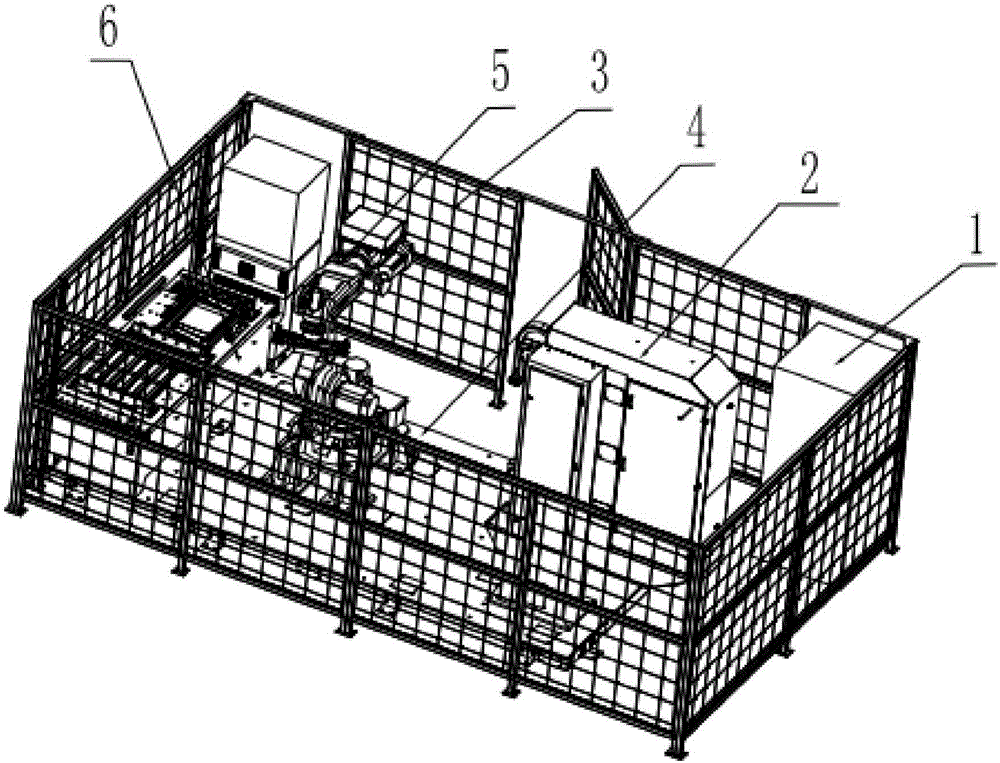

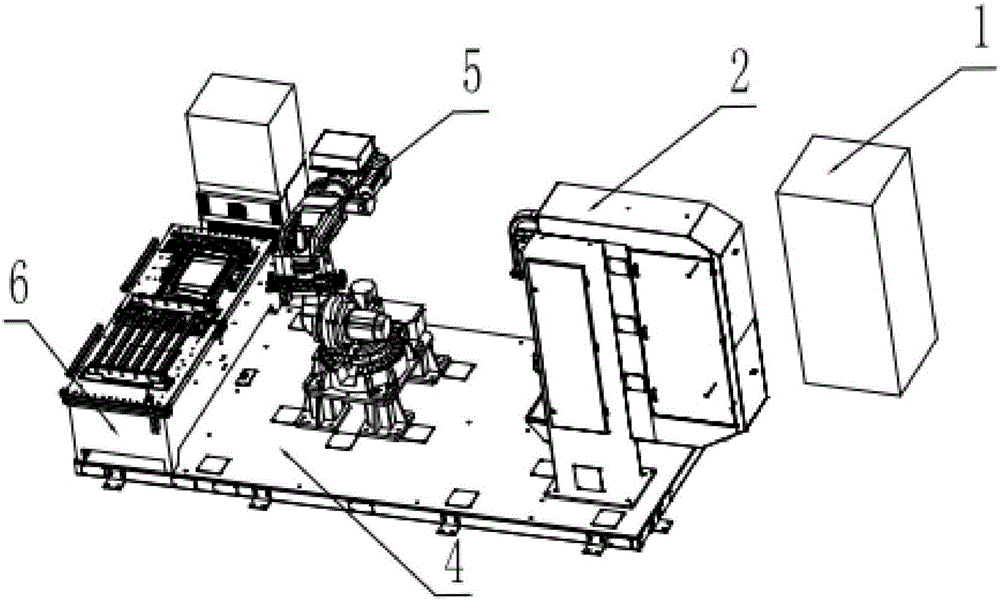

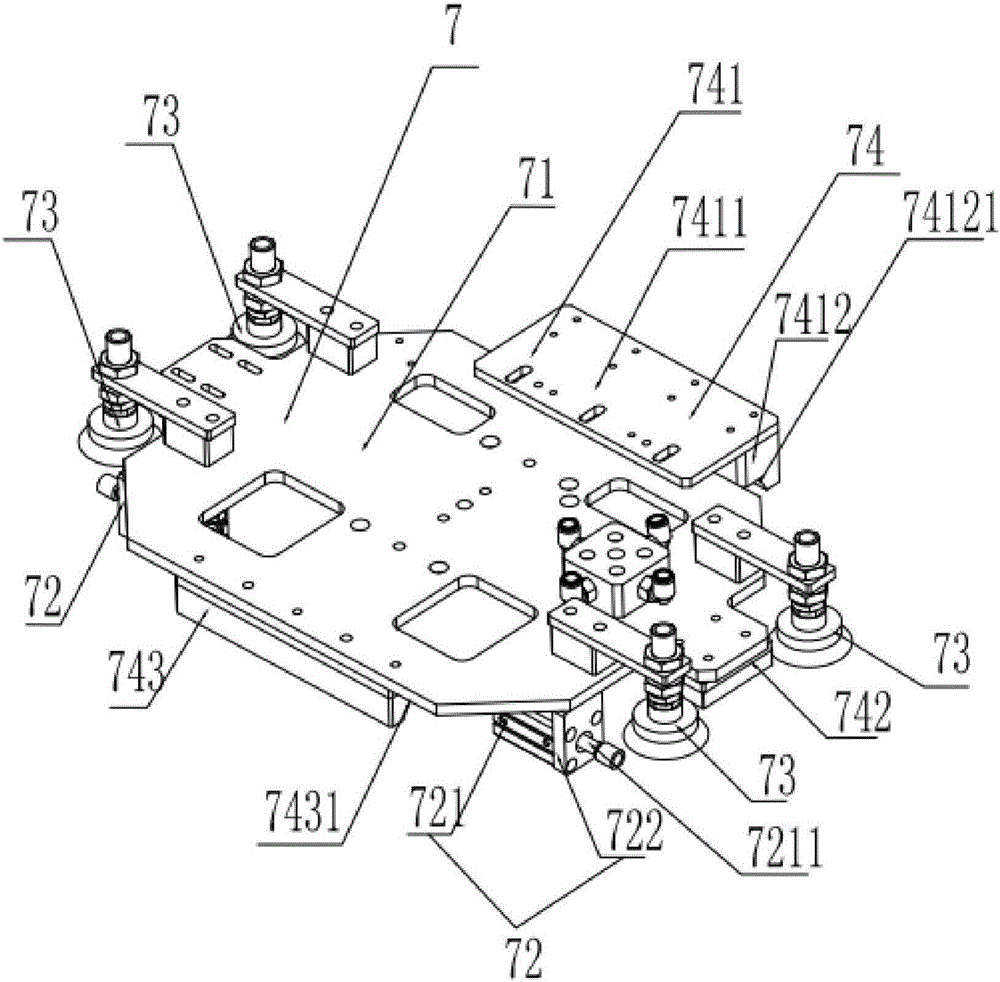

[0024] like Figure 1-4 As shown, a range hood panel and oil tank grinding and wire drawing system include a dust removal cabinet 1, a double-station force-controlled belt machine 2, a protective net 3, a system base 4, a robot 5, and a loading and unloading table 6. The dust removal cabinet 1 It is set at a corner of the system, the system base 4 is set at the bottom of the system, the double-station force-controlled belt sander 2 is set at the edge of the system base 4, and the robot 5 is set at the In the middle of the system base 4, the loading and unloading platform 6 is arranged on the edge of the other end of the system base 4 opposite to the double-station force control belt machine 2, and the protective net 3 is arranged outside the system , is characterized in that: it also includes a rob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com