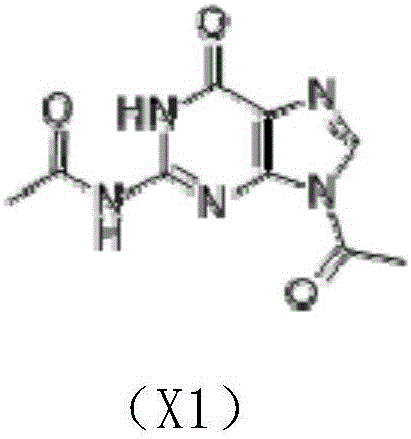

Preparation method of N2,9-diacetylguanine

A technology of diacetylguanine and guanine, which is applied in the chemical field, can solve the problem that the reaction conversion rate only reaches 60%, and achieve the effects of good particle size, reduced energy consumption, and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

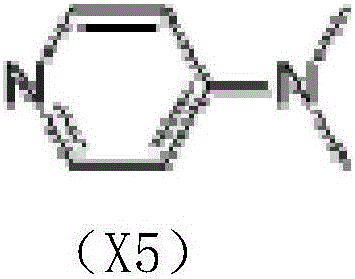

[0027] In a 500ml three-necked flask, add 240g of pyridine, 20g of guanine, and 1g of DMAP (4-dimethylaminopyridine) in sequence, stir to dissolve, and cool to -5°C in an ice bath. Add 42g of acetyl chloride into the separatory funnel, and slowly add it dropwise while stirring. Control the dropping process for 25-35min, and the temperature is lower than 10°C. After the dropwise addition, the mixture was stirred at room temperature for 2.5 h to obtain the X1 reaction solution.

[0028] Distill the reaction solution X1 under reduced pressure to control the pressure to -0.09Mpa. When the temperature rises to 51°C, pass the effluent acetyl chloride into water. When the temperature rises to 92°C, collect the effluent pyridine and recover it for use. A solid containing X1 precipitated out.

[0029] Add the obtained X1 solid into a flask containing 140 g of distilled water, stir for 40 min, and suction filter at room temperature to obtain a solid containing X1.

[0030] Add the s...

Embodiment 2

[0033] In a 500ml three-necked flask, add 240g of pyridine, 20g of guanine, and 1g of DMAP (4-dimethylaminopyridine) in sequence, stir to dissolve, and cool to -5°C in an ice bath. Add 42g of acetyl chloride into the separatory funnel, and slowly add it dropwise while stirring. Control the dropping process for 25-35min, and the temperature is lower than 10°C. After the dropwise addition, the mixture was stirred at room temperature for 2.5 h to obtain the X1 reaction solution.

[0034] Distill the reaction solution X1 under reduced pressure to control the pressure to -0.09Mpa. When the temperature rises to 51°C, pass the effluent acetyl chloride into water. When the temperature rises to 92°C, collect the effluent pyridine and recover it for use. A solid containing X1 precipitated out.

[0035] Add the obtained X1 solid into a flask containing 140 g of distilled water, stir for 40 min, and suction filter at room temperature to obtain a solid containing X1.

[0036] Add the s...

Embodiment 3

[0039] In a 500ml three-necked flask, add 240g of pyridine, 20g of guanine, and 1g of DMAP (4-dimethylaminopyridine) in sequence, stir to dissolve, and cool to -5°C in an ice bath. Add 42g of acetyl chloride into the separatory funnel, and slowly add it dropwise while stirring. Control the dropping process for 25-35min, and the temperature is lower than 10°C. After the dropwise addition, the mixture was stirred at room temperature for 2.5 h to obtain the X1 reaction solution.

[0040] Distill the reaction solution X1 under reduced pressure to control the pressure to -0.09Mpa. When the temperature rises to 51°C, pass the effluent acetyl chloride into water. When the temperature rises to 92°C, collect the effluent pyridine and recover it for use. A solid containing X1 precipitated out.

[0041] Add the obtained X1 solid into a flask containing 140 g of distilled water, stir for 40 min, and suction filter at room temperature to obtain a solid containing X1.

[0042] Add the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com