Preparation method of polyphenylene sulfide sulphone ketone with high molecular weight

A polyphenylene sulfide, high molecular weight technology, applied in the field of polymer resin synthesis, can solve the problems of poor color, insufficient mechanical properties, low molecular weight, etc., achieve good reproducibility, solve product quality instability, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

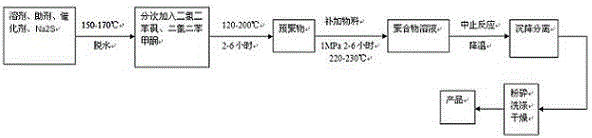

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] Such as figure 1 As shown, a manufacturing method of high molecular weight polyphenylene sulfide sulfone ketone, including raw materials: sodium sulfide, 4,4'-dichlorodiphenyl sulfone and 4,4'-dichlorobenzophenone, solvent: N- Methylpyrrolidone, auxiliary agent: sodium hydroxide, catalyst, sodium benzoate; Its main characteristic is: the mole of described sodium sulfide and 4,4'-dichlorodiphenyl sulfone and 4,4'-dichlorobenzophenone The ratio is 1.05::0.8:0.2; the first polymerization reaction of the raw material and the solvent, the auxiliary agent and the catalyst obtains a prepolymer, and the second polymerization reaction obtains a polymer solution; the ratio of the raw material and the solvent, the auxiliary agent and the catalyst The polymerization reaction temperature is 170°C-270°C, the pressure condition is 0MPa-1MPa, and the required time is 3h-8h; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com