Control system for suspending hole drilling trolley for subway tunnel and control method

A control system and tunnel technology, which are applied in the automatic control system of drilling, drilling equipment and methods, and earth-moving drilling and mining, etc. The effect of improving punching efficiency, eliminating safety hazards and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The composition and working principle of the present invention will be described in detail below with reference to the accompanying drawings and embodiments.

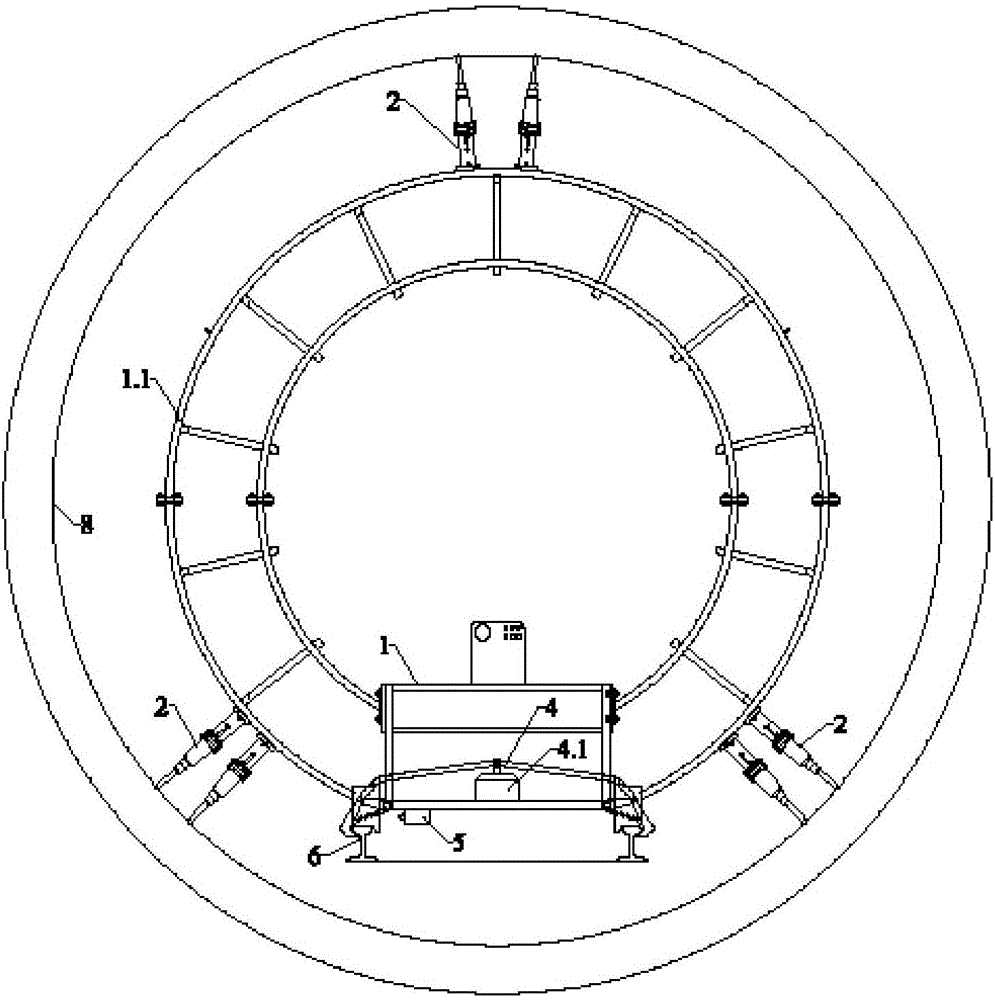

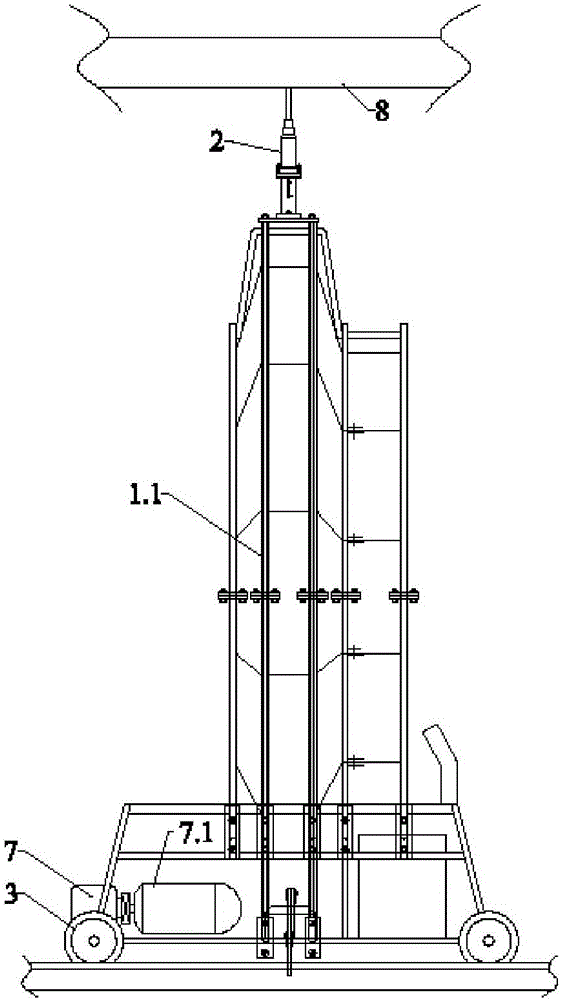

[0025] attached figure 1 And attached figure 2 It shows a situation that a subway tunnel suspension punching trolley is installed in the tunnel, wherein the punching trolley 1 includes a circular slideway 1.1 corresponding to the circular tunnel section 8, on the circular slideway 1.1 Several groups of punching drive devices 2 are installed, and the punch drive device 2 can move along the annular slideway 1.1 and can be fixed at any position.

[0026] The trolley 1 is also equipped with a traveling device 7 and a traveling motor 7.1 for driving the trolley, a traveling brake device 4 and a brake solenoid valve 4.1, a probe 5 for detecting the traveling distance, and the punching trolley 1 passes through the traveling wheels 3 in the paved Walk on the track 6.

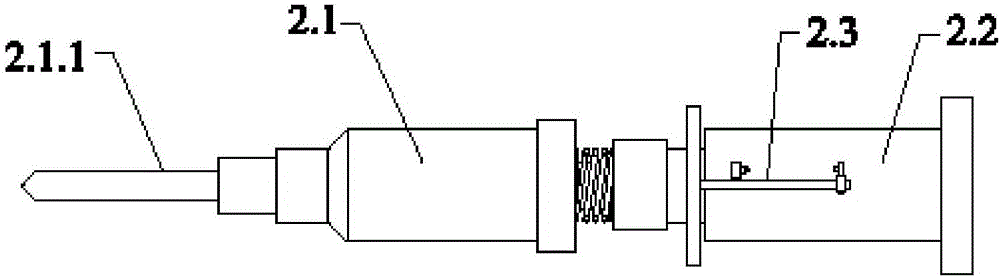

[0027] see attached image 3 , wherein the perf...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap