Variable-displacement oil pump

A technology of displacement machine and oil pump, applied in the direction of lubrication pump, mechanical equipment, engine components, etc., can solve the problems of increasing the cost of parts, increasing the structural complexity of the oil pump, increasing the overall volume of the oil pump, etc., to simplify the structure and reduce the product. Cost, effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

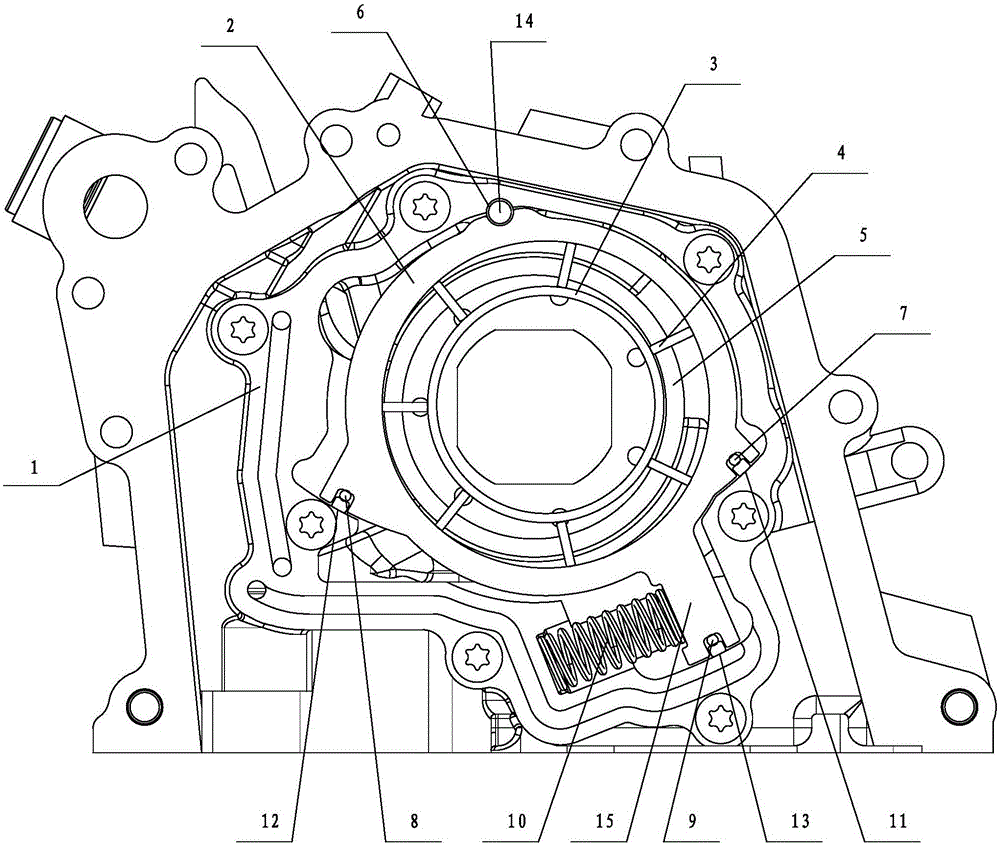

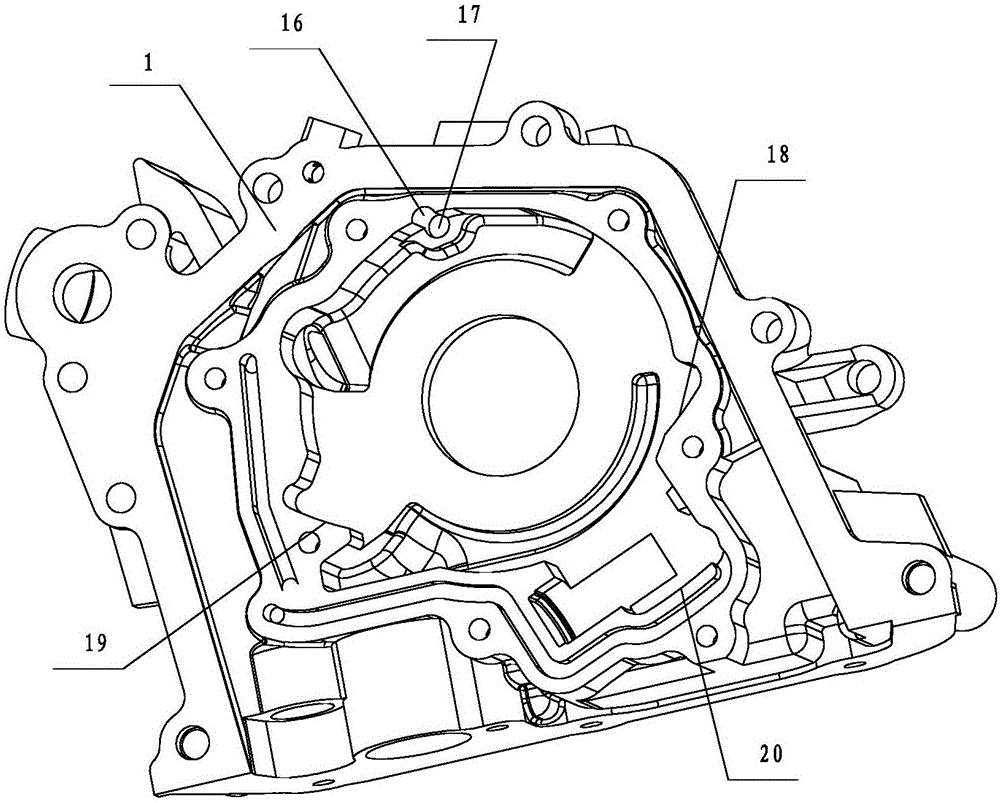

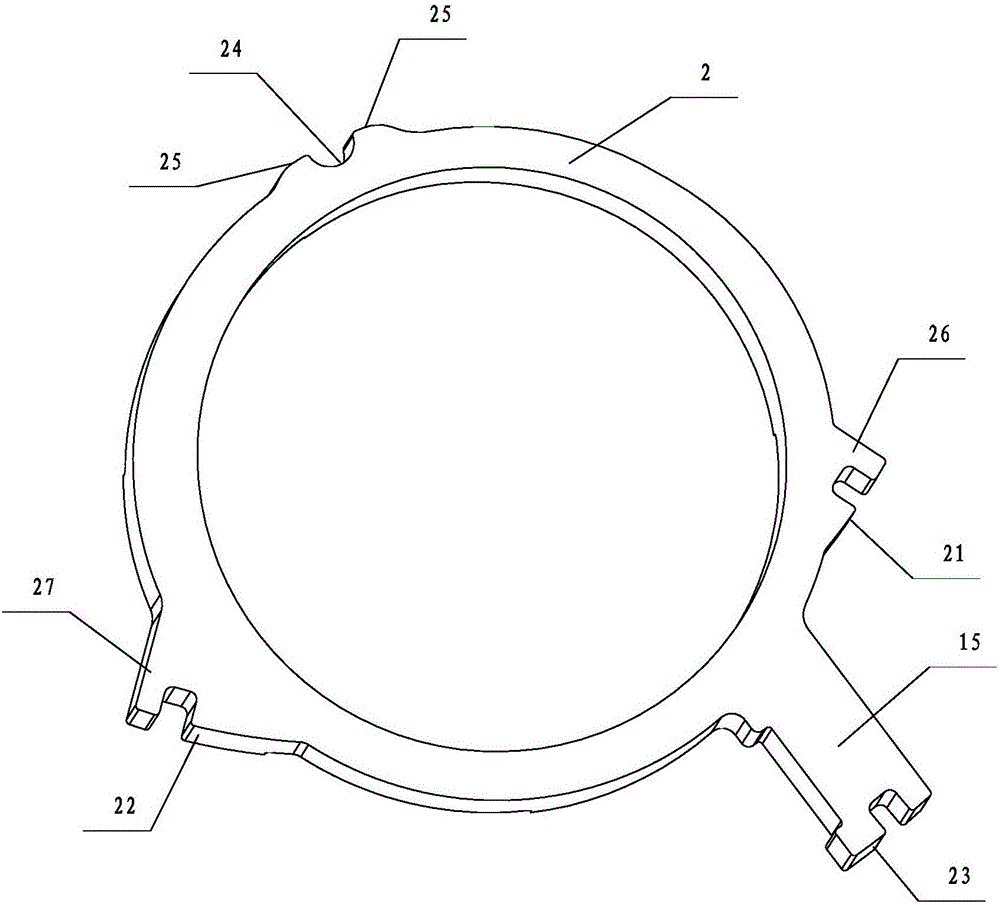

[0016] Depend on Figure 1 ~ Figure 4 The shown schematic diagram of the principle of the variable displacement oil pump of the present invention shows that it includes a pump body 1, a swing ring 2, a spring 10, an eccentric ring 3 and a plurality of blades 4 that are connected to the main oil passage of the system through a feedback oil passage. The vane wheel 5, the pump body 1 is provided with an inner cavity, and the eccentric ring 3 and the vane wheel 5 are sequentially arranged in the inner cavity from outside to inside, and a plurality of vanes 4 divide the cavity between the eccentric ring 3 and the vane wheel 5 into a plurality of hydraulic chambers with different volume values. It is characterized in that: a hinge point 6, a first sealing point 11, a second sealing point 12 and a third sealing point 13 are respectively pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com