Metal smelting waste slag high-temperature waste heat generation device

A technology of metal smelting and waste heat power generation, which is applied in the field of mechanical equipment, can solve the problems of low utilization rate, excessive metal consumption, and low utilization rate of waste slag and waste heat, and achieve the effect of reducing labor intensity and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

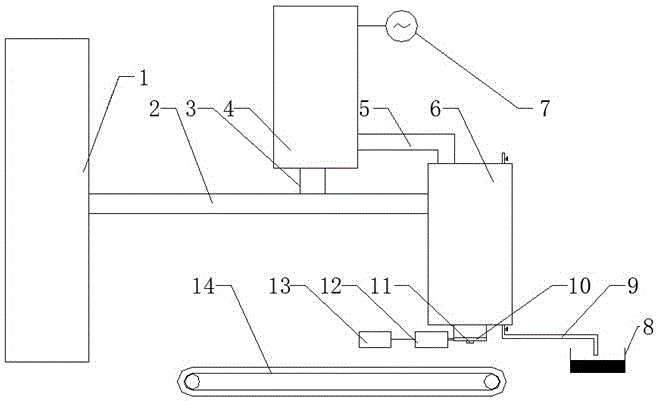

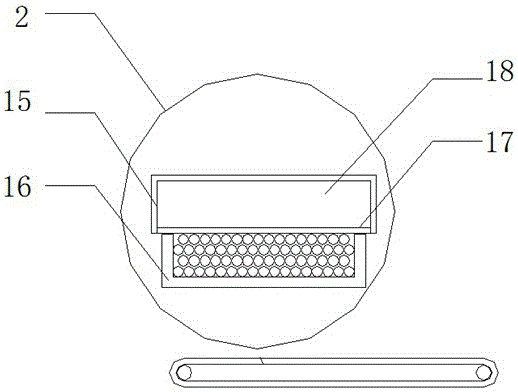

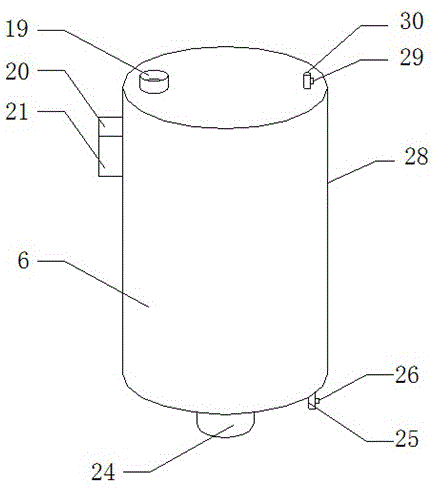

[0017] Specific implementation method: the waste slag from the metal smelting furnace 1 enters the conveying device 2 and is sent to the steam boiler 1. The waste slag follows the heat emitted during the movement of the adiabatic conveying tank 16 and enters the water holding chamber 18 through the heat conducting plate 17 for heating. The water in the water chamber 18 generates water vapor, which is then transported to the steam turbine 4 through the steam pipe-3. This process improves the waste heat utilization rate. The waste residue enters the waste residue inlet 21 through the conveying device 2, and then enters the waste residue storage chamber 23. The waste residue is placed in the waste residue chamber. The heat dissipated in the waste residue storage chamber 23 enters the water supply chamber 22 through the heat conduction plate 26, heats the water in the water supply chamber 22 to generate water vapor, and then transports it to the steam turbine 4 through the steam tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com