A kind of separation method of aqueous organic matter

A separation method and technology for organic substances, which can be applied in separation methods, purification/separation/stabilization of organic compounds, organic chemical methods, etc., and can solve the problems of reducing the utilization rate of molecular sieve moldings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

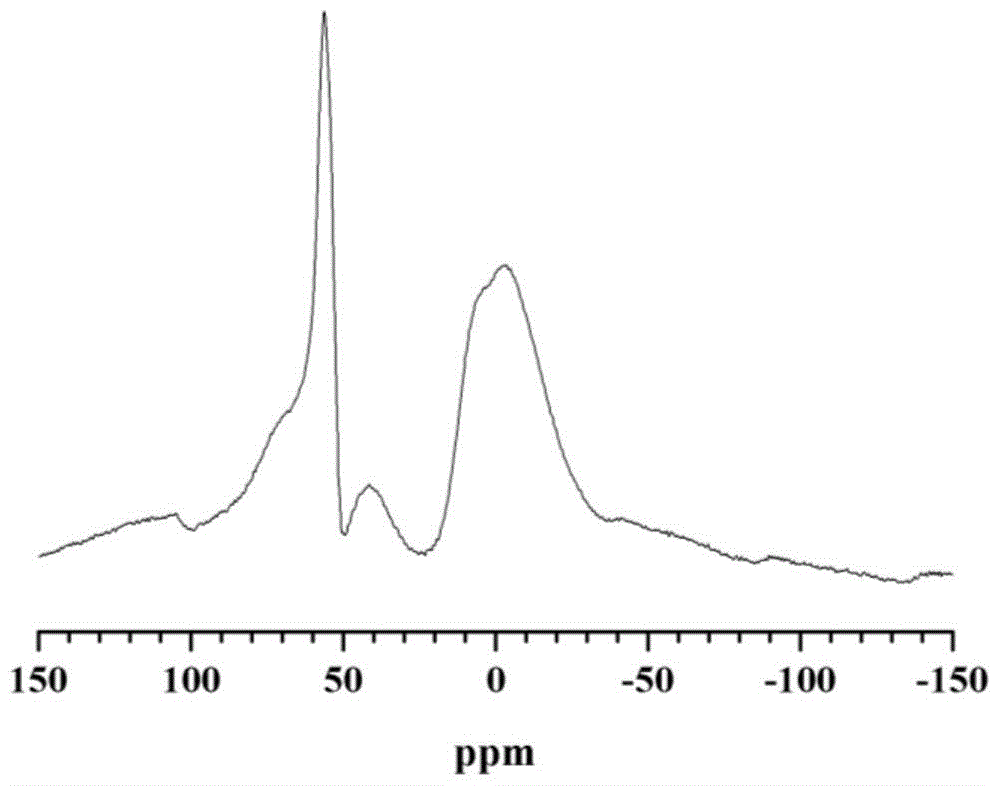

[0033] Preparation of molecular sieve moldings capable of self-complementing aluminum: hydrophilic ZSM-5 molecular sieve and binder Al 2 o 3The coating film is formed, and the modifying elements are introduced through the impregnation method. The weight composition of the molecular sieve molding is: ZSM-5 molecular sieve 60%, Ge element 1%, Al 2 o 3 34%. The molecular sieve molding 27 Al NMR spectrum see figure 1 , the weight content of skeleton aluminum is calculated to be 16.92% by peak integration.

[0034] Separation process: the acetic acid-water mixture (the volume content of acetic acid is 70%) is passed into a tower filled with a molecular sieve molding film for separation. Using vapor permeation separation, water molecules preferentially pass through the molecular sieve molding membrane. Adjust the feed rate to achieve the required amount of water in the effluent. After adsorption at 70°C for 10 hours, the feeding of the acetic acid-water mixture was stopped. ...

Embodiment 2

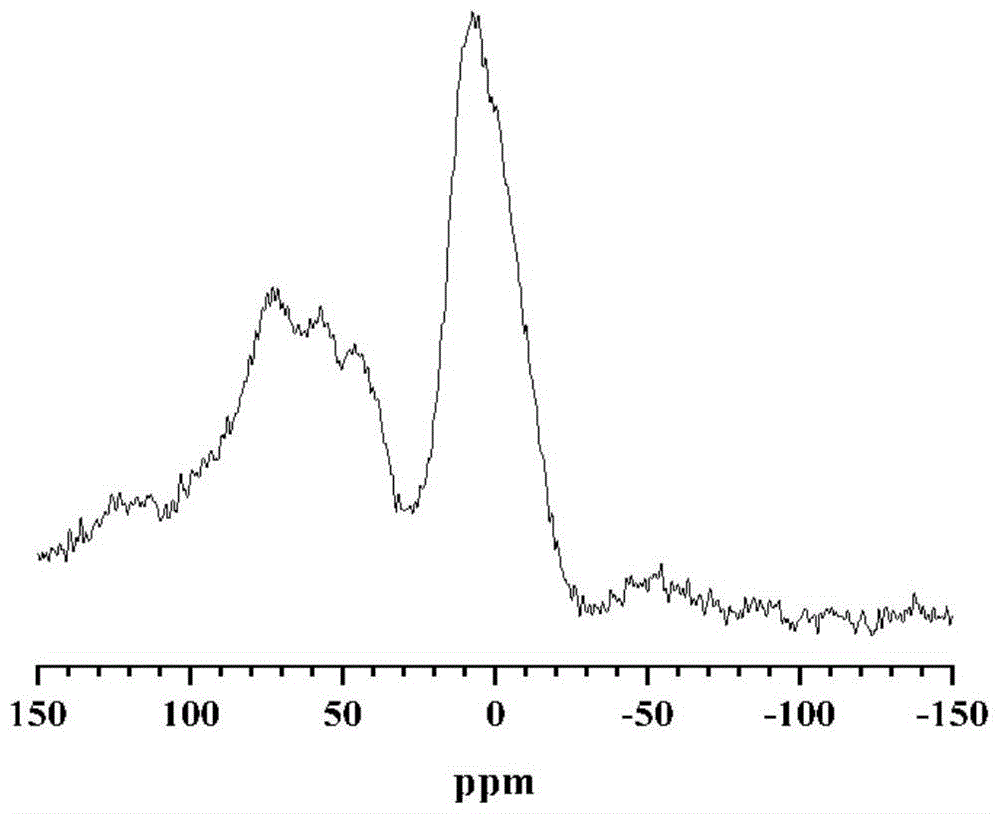

[0038] Preparation of molecular sieve moldings that can self-replenish aluminum: 4A molecular sieve is extruded with binder pseudo-boehmite and silica-alumina gel, and modifying elements are introduced by mechanical mixing. The molecular sieve molding weight composition is: 4A molecular sieve 55%, Al 2 o 3 35%, SiO 2 10%, the calculated skeleton aluminum weight content is 18.62%.

[0039] Separation process: the dichloromethane-water mixture (volume content of water is 0.2%) is passed into a tower filled with molecular sieve moldings for separation. With adsorption separation, water is preferentially adsorbed by molecular sieve moldings. Adjust the feed rate so that the water content in the effluent meets the requirements. After 20 hours of adsorption at 40°C, the feed of the dichloromethane-water mixture was stopped. The molecular sieve molded product was desorbed by maintaining at 200° C. for 8 hours. After 2,000 hours of adsorption-desorption operation, the molecular ...

Embodiment 3

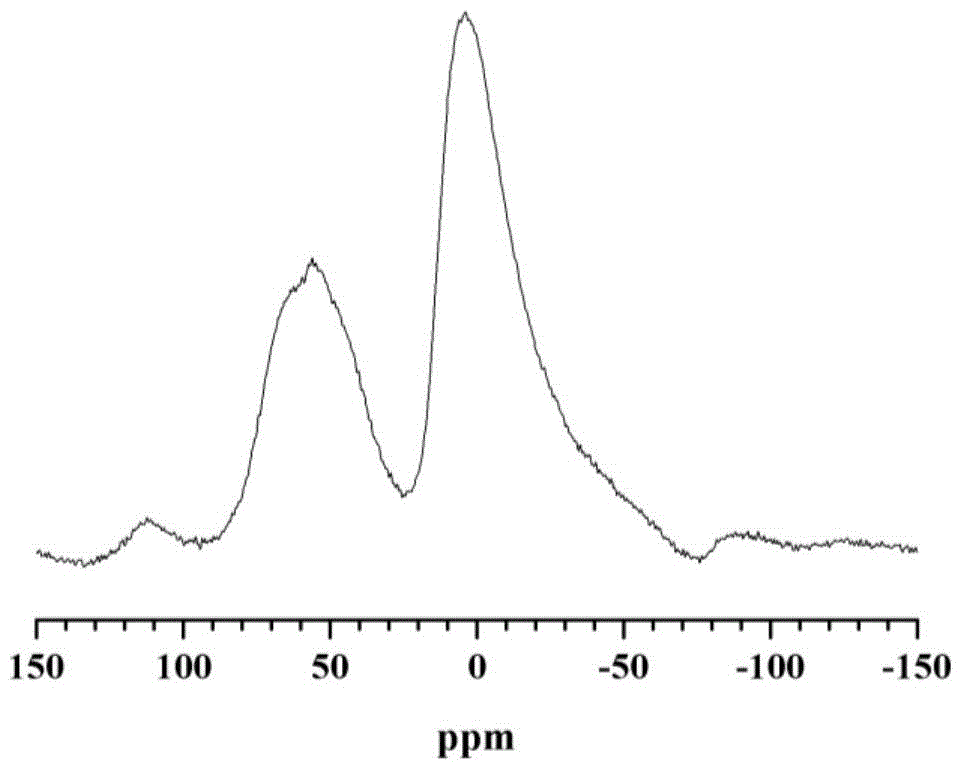

[0042] Preparation of molecular sieve moldings that can self-replenish aluminum: 4A molecular sieve and adhesive silica-alumina gel coating film molding, the carrier is an inert ceramic tube. The weight composition of molecular sieve molding is: molecular sieve 65%, Al 2 o 3 30%, SiO 2 5%. through 27 According to Al NMR, the aluminum content of the framework is 15.12%.

[0043] Separation process: the ethylene glycol-water mixture (the volume content of water is 80%) is passed into a tower filled with a molecular sieve formed product membrane for separation. With vapor permeation separation, water molecules are adsorbed in gaseous form and pass through the membrane pores of molecular sieve moldings. Adjust the feed rate to achieve the required amount of water in the effluent. After adsorption at 120° C. for 100 hours, the feeding of the ethylene glycol-water mixture was stopped. The molecular sieve molded product was desorbed by maintaining at 300° C. for 15 hours. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com