Device and method of testing temperature of each part of dry clutch

A dry clutch and testing device technology, which is applied in the testing of machines/structural components, testing of mechanical components, measuring devices, etc., can solve the troublesome operation of the wireless temperature acquisition system, cannot represent the actual temperature, and cannot guarantee the accuracy of temperature measurement, etc. problem, to achieve the effect of simple and easy technical means and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

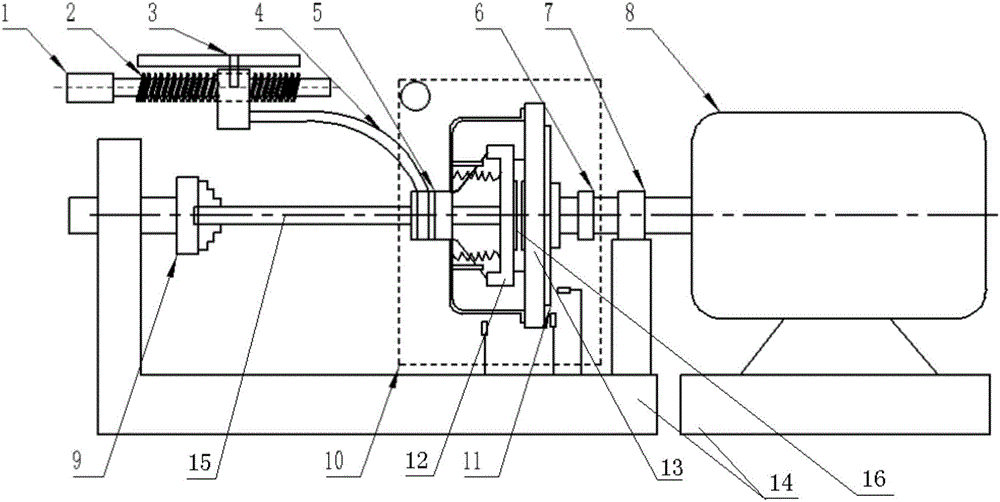

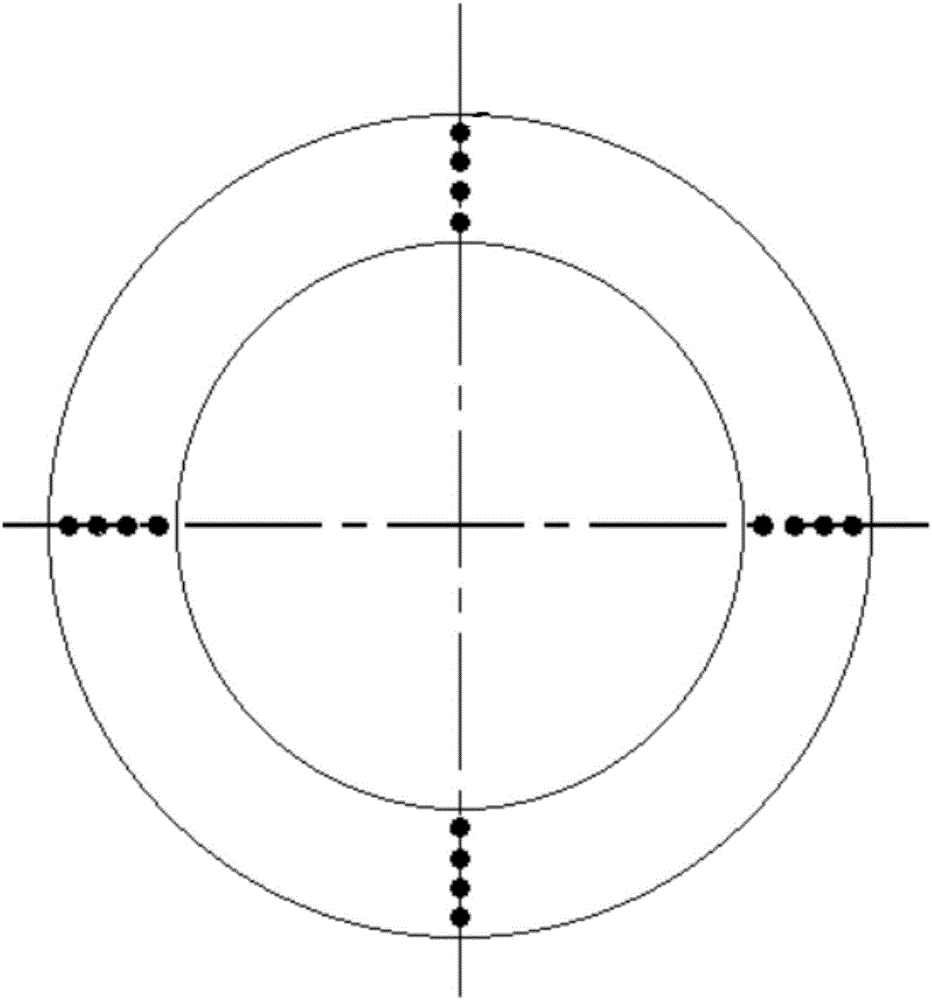

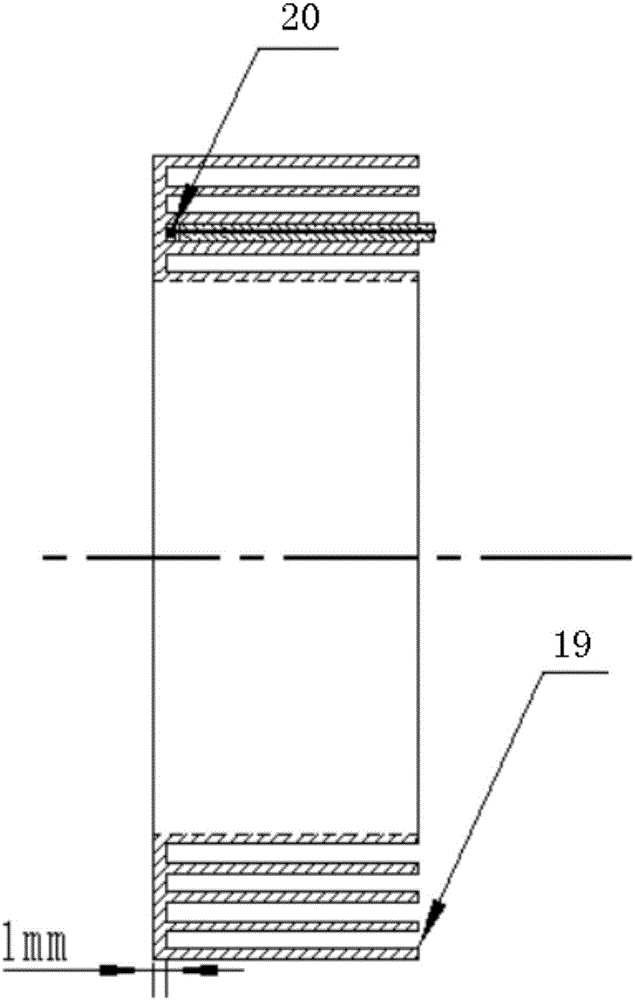

[0036] like Figures 1 to 5 shown. The invention discloses a temperature testing device for each component of a dry clutch, comprising a frame 14, a variable frequency motor 8 arranged on the right side of the frame 14, a fixed shaft 15 arranged on the left side of the frame 14, and one end of the fixed shaft 15 The pressure plate 12 and the flywheel 13 arranged on the rotating shaft of the variable frequency motor 8; the pressure plate 12 and the flywheel 13 are arranged opposite to each other, and a friction plate 16 is installed between the pressure plate 12 and the flywheel 13; the fixed shaft 15 passes through The mechanical chuck 9 is fixed on the frame 14 .

[0037] The pressure plate 12 and the friction plate 16 are sleeved on the fixed shaft 15 from left to right. The pressure plate 12 and the flywheel 13 are rotating parts, which are driven by the frequency conversion motor 8 to rotate synchronously, and the pressure plate 12 can be relatively fixed. The shaft 15 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com