Low temperature-seepage-force coupling effect tunnel model test system and test method

A technology of tunnel model and test system, applied in the field of geotechnical engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

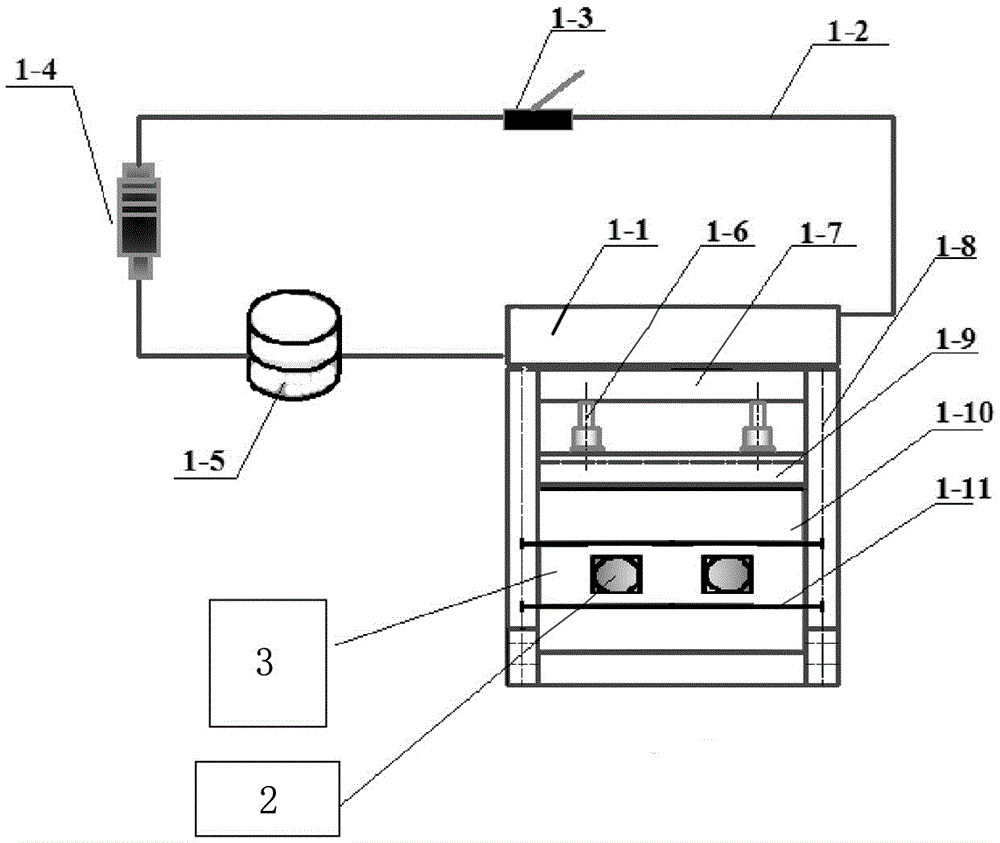

[0032] In order to make the technical solutions and advantages of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

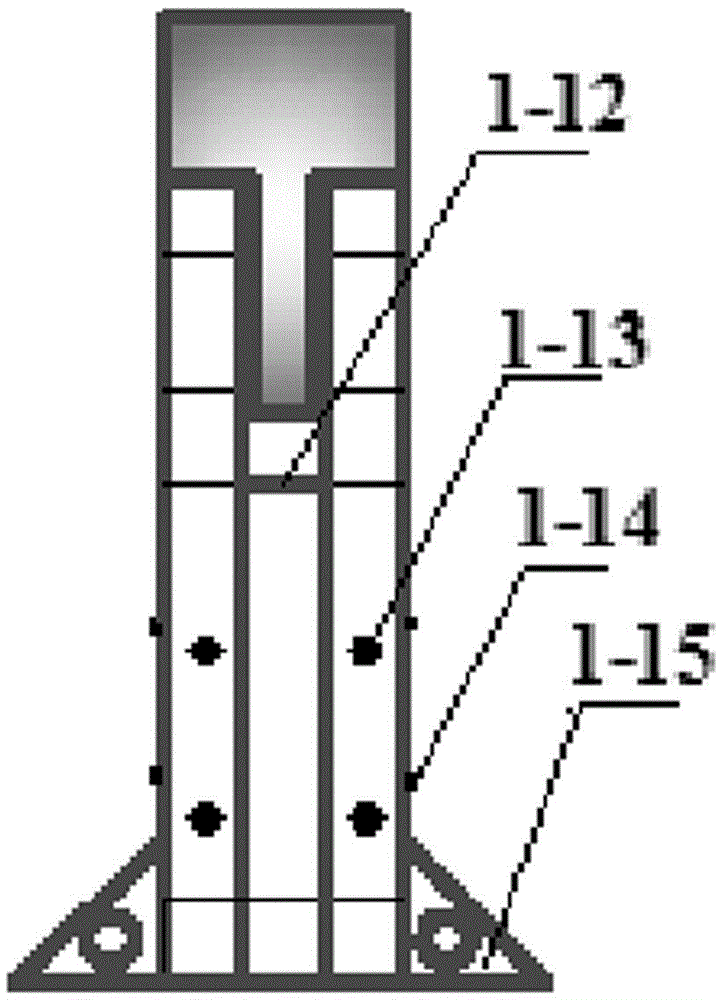

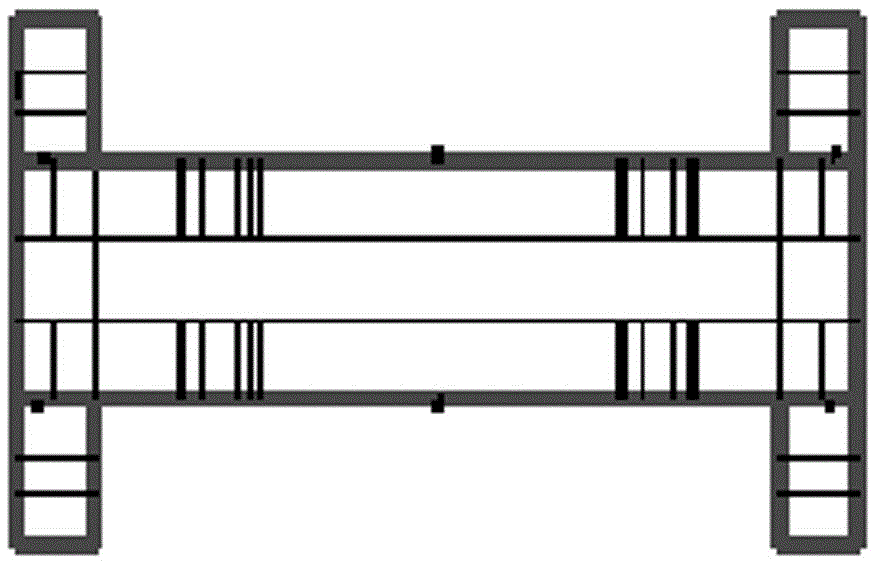

[0033] Figure 1-Figure 3 As shown, the main loading frame 1 of the steel structure is related to the bottom pressure platform, and the bottom pressure platform 1-12 is connected with the pressure frames 1-8 on both sides, and the 1-8 is connected with the working The upper beam 1-7 of the beam is welded, the bottom pressure platform and 1-8 are connected with the front and rear liftable automatic baffles 1-10, and the beam 1-7 of the I-beam is connected with the synchronous jacking jack 1-10 6 are connected, and the jack 1-6 is connected with the pressure transmission I-beam 1-9.

[0034] Such as Figure 1-Figure 3 As shown, the main loading part 1 of the steel structure also includes a sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com