Triaxial test apparatus and method suitable for weak rocks

A triaxial test, rock technology, applied in the direction of measuring device, using stable tension/pressure test material strength, strength characteristics, etc., can solve the problems of high price, large floor area, high cost, etc., and achieve low cost and convenience Easy to use and device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

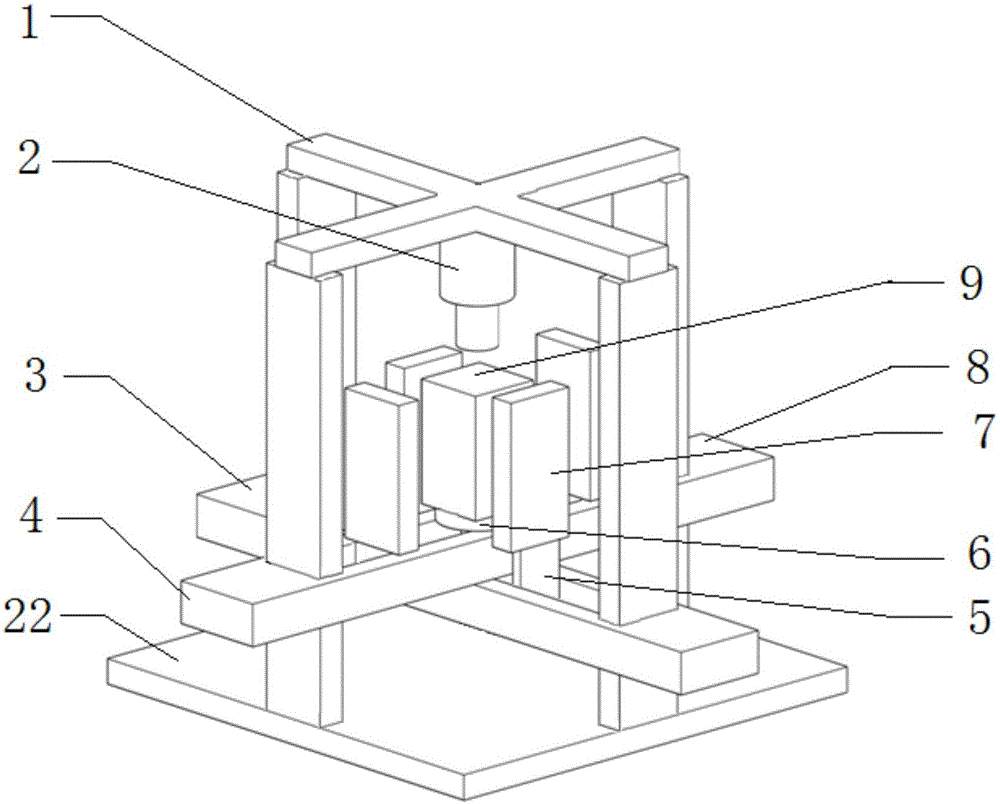

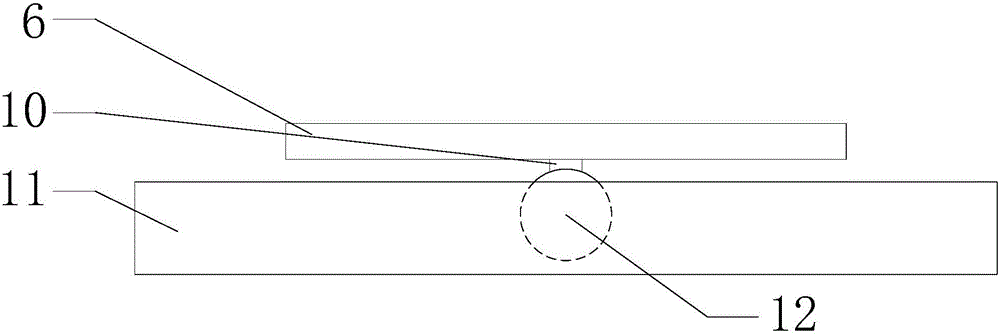

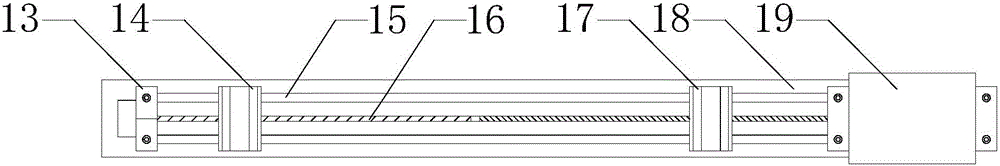

[0047] Embodiment: a kind of triaxial test device applicable to weak rock, its structure is as follows Figure 1-3 shown, including:

[0048] The base 22 is fixedly connected with a support 1; the support 1 is a hollow structure, and the support 1 has a side plate and a cross-shaped top plate fixedly connected with the side plate, and the middle part of the lower surface of the cross-shaped top plate and the Z-axis stress loading mechanism 2 fixed connections.

[0049] The side plate is divided into upper and lower parts, the lower part is fixedly connected with the base 22, the upper part is fixedly connected with the cross-shaped top plate, and the upper part and the lower part are fixedly connected with the stress loading mechanism.

[0050] The stress loading mechanism includes two, namely an X-axis stress loading mechanism 4 and a Y-axis stress loading mechanism 3 , and the X-axis stress loading mechanism 4 is located above the Y-axis stress loading mechanism 3 .

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com