Device for improving laser trimming precision of extreme-value thick film resistor

A thick-film resistor, laser trimming technology, applied in resistors, measuring devices, resistor manufacturing, etc., can solve the problem of low measurement accuracy, and achieve the effects of high trimming accuracy, improved measurement accuracy, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

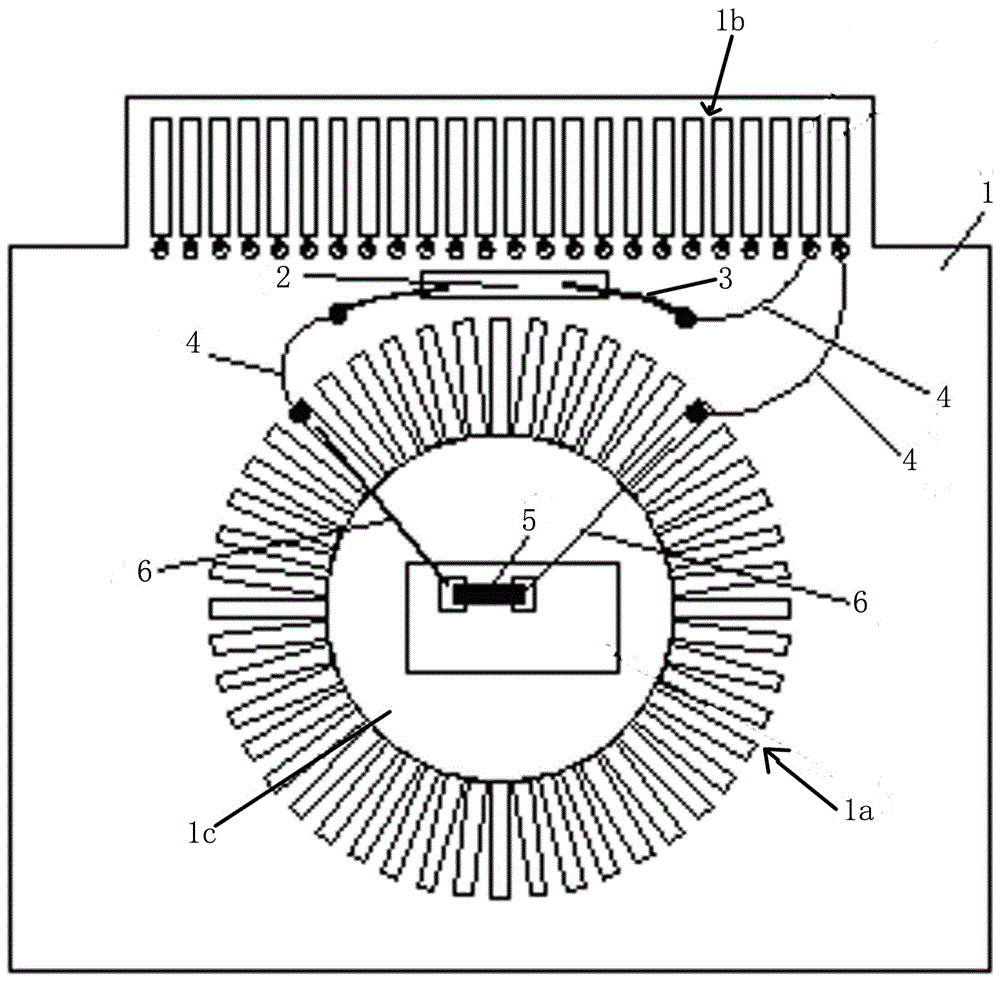

[0020] Such as figure 1 As shown, a device for improving the accuracy of laser trimming of extreme value thick film resistors, which includes a probe card 1, a row of output terminals 1b are arranged on the front of the probe card 1, and the output terminals 1b are inserted into the laser trimming resistance not shown in the figure The input end of the mechanical resistance measurement system, the output end of the probe card and the designated input end are connected in one-to-one correspondence.

[0021] There is an opening 1c in the middle of the probe card 1, and a welding pad 1a is provided on the probe card 1 around the opening 1c. The welding pad 1a is composed of a long strip-shaped electrode distributed radially.

[0022] A resistor 2 with a resistance value of 100Ω is provided on the probe card 1 between a designated port of the output terminal 1b and the pad 1a.

[0023] On the resistor body of the resistor 2, there are two lead-out terminals 3 on the left and righ...

Embodiment 2

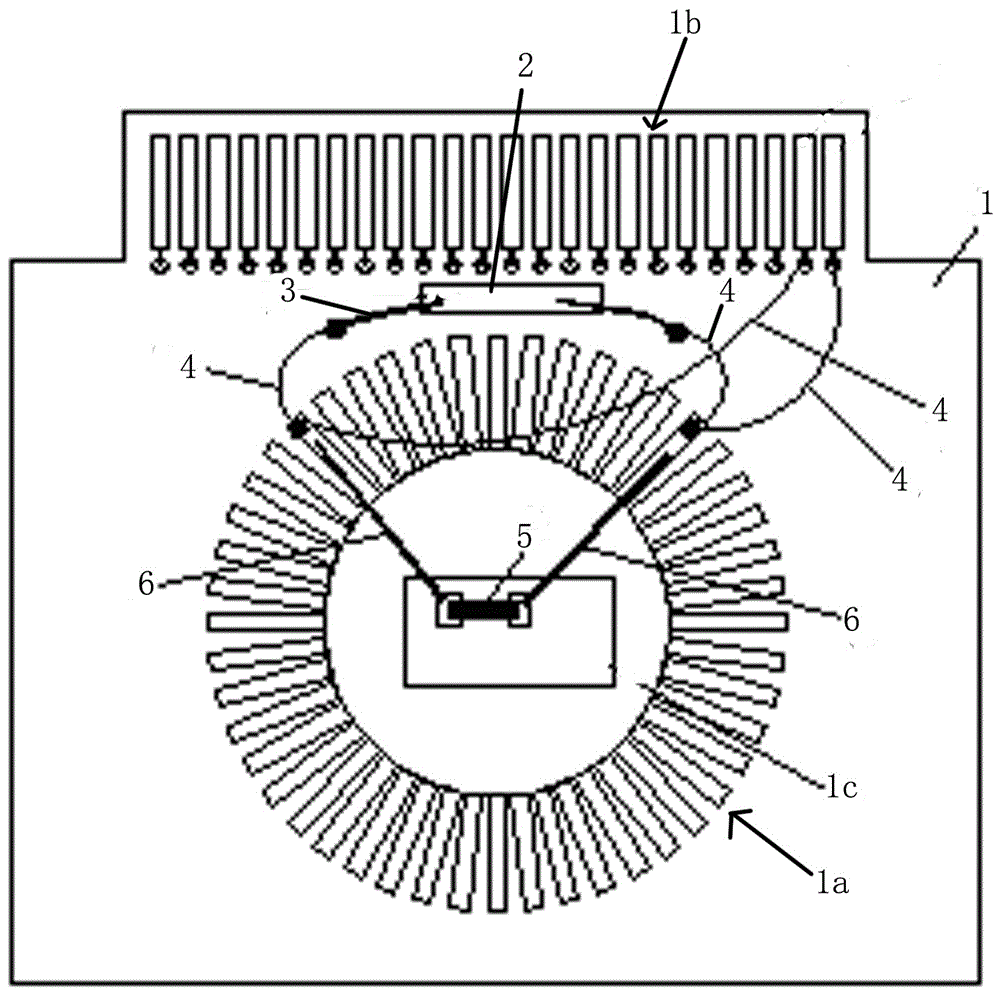

[0031] Such as figure 2 As shown, a device for improving the accuracy of laser trimming of extreme value thick film resistors, which includes a probe card 1, a row of output terminals 1b are arranged on the front of the probe card 1, and the output terminals 1b are inserted into the laser trimming resistance not shown in the figure The input end of the mechanical resistance measurement system, the output end of the probe card and the designated input end are connected in one-to-one correspondence.

[0032] There is an opening 1c in the middle of the probe card 1, and a welding pad 1a is provided on the probe card 1 around the opening 1c. The welding pad 1a is composed of a long strip-shaped electrode distributed radially.

[0033] A resistor 2 with a resistance value of 100Ω is provided on the probe card 1 between a designated port of the output terminal 1b and the pad 1a.

[0034] A lead-out terminal 3 is respectively provided on the left and right ends of the resistor body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com