Partial discharge detection system for intermediate joint of 10kV insulated tubular bus

A technology for partial discharge detection and intermediate joints, which is applied in the direction of measuring electricity, measuring devices, and measuring electrical variables, etc., can solve the problems that the research on partial discharge detection of insulating tubular busbars and field work have not yet been carried out, and achieve friendly interface and rich decision-making information , information display intuitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

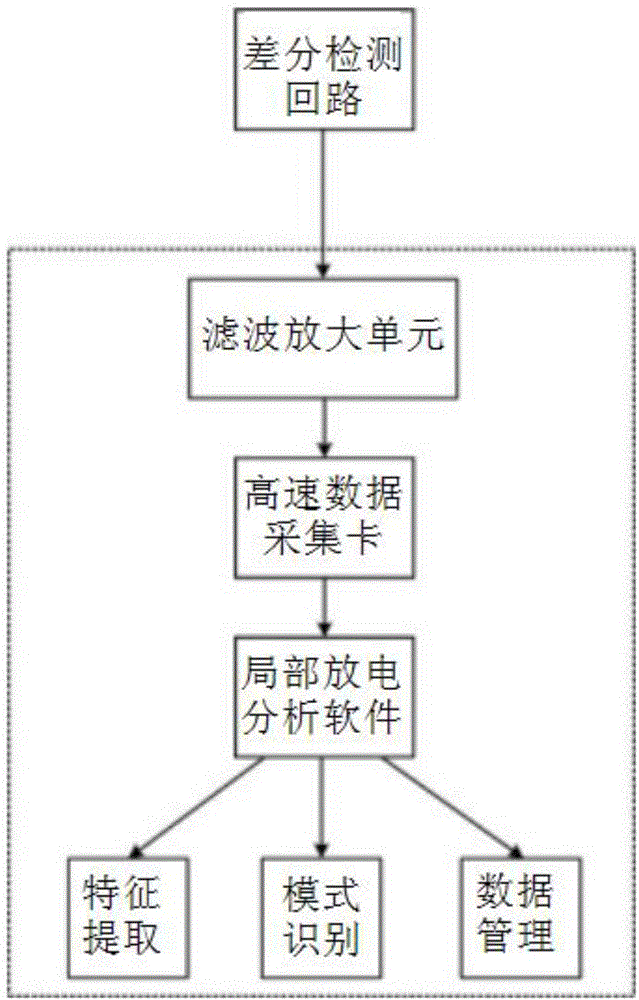

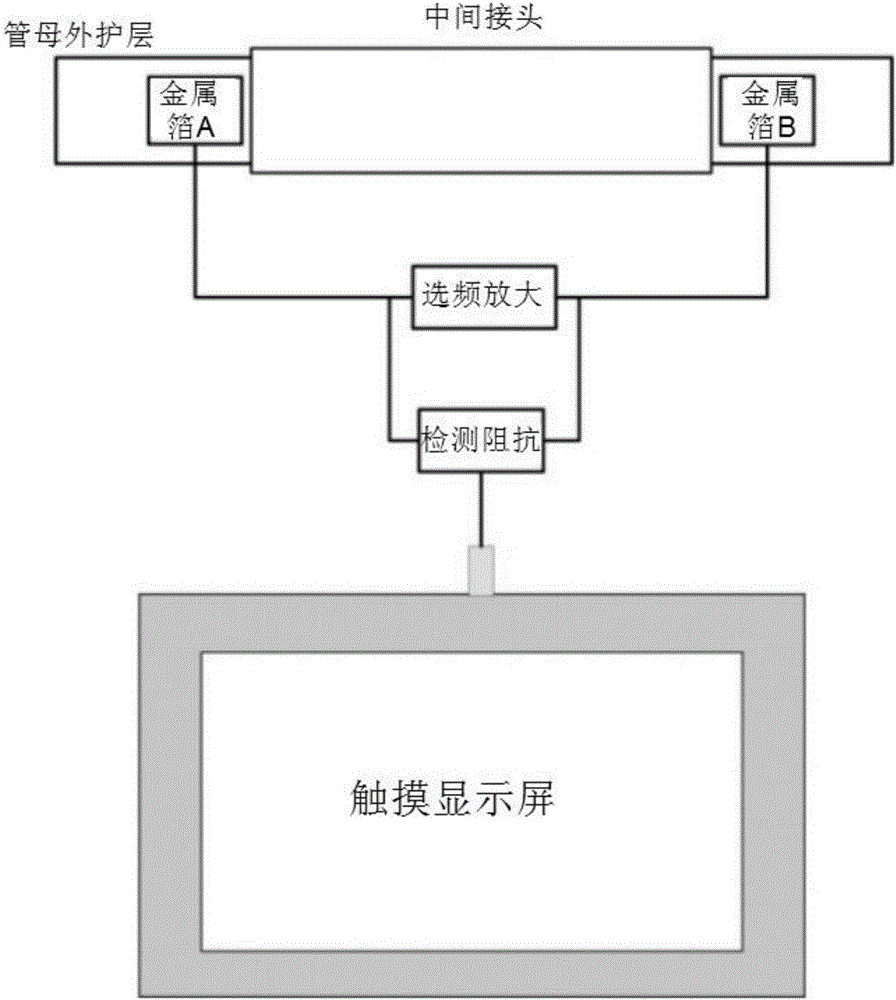

[0014] A 10kV insulating tubular bus intermediate joint partial discharge detection system, such as figure 1 and figure 2 As shown, it includes a differential detection circuit, a filter amplification unit, a high-speed data acquisition card, a computer host and a touch screen display. The differential detection circuit is composed of a capacitive sensor and a detection impedance. The capacitive sensor is laid on both sides of the intermediate joint of the tubular bus bar with metal foil electrodes, and an equivalent capacitance is formed between the outer sheath and the grounding screen. The capacitance on both sides and the detection The impedance forms a differential detection loop. When a partial discharge occurs in the tubular busbar, after it propagates to the two capacitors, the formed signal is canceled on the detection impedance; when a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com