Manufacturing method for electromagnetic wave structure stealth

A manufacturing method and electromagnetic wave technology, applied to chemical instruments and methods, pharmaceutical equipment, electrical digital data processing, etc., can solve problems such as poor stealth effect, mismatched surface impedance, large cumulative error, etc., and achieve improved combat penetration Ability and survivability, good surface impedance matching, effect of improved absorbing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, taking X-band horizontal wing part plane stealth structure manufacturing as an embodiment.

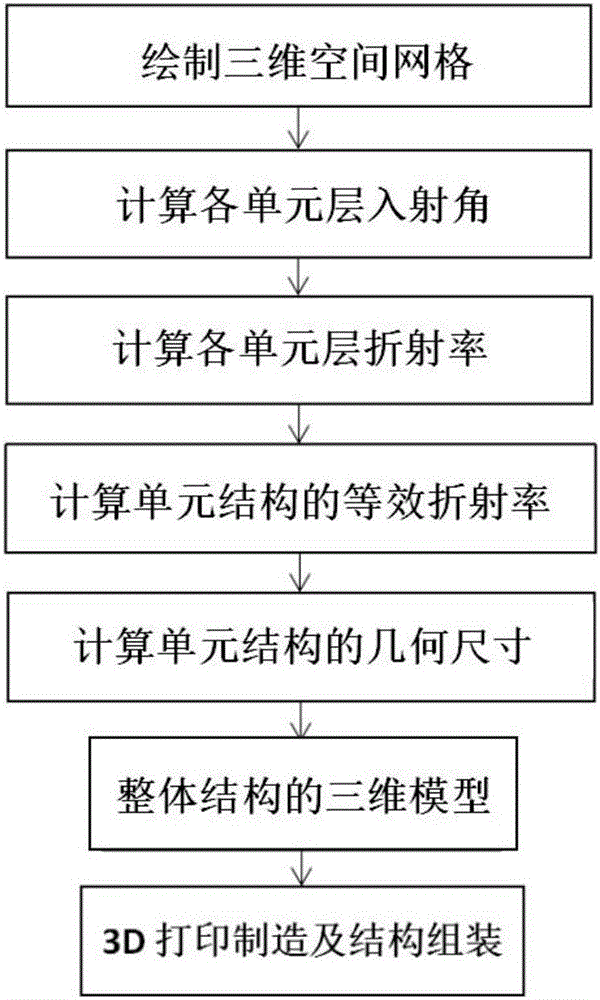

[0027] refer to figure 1 , a method for manufacturing an electromagnetic wave structure invisible, comprising the following steps:

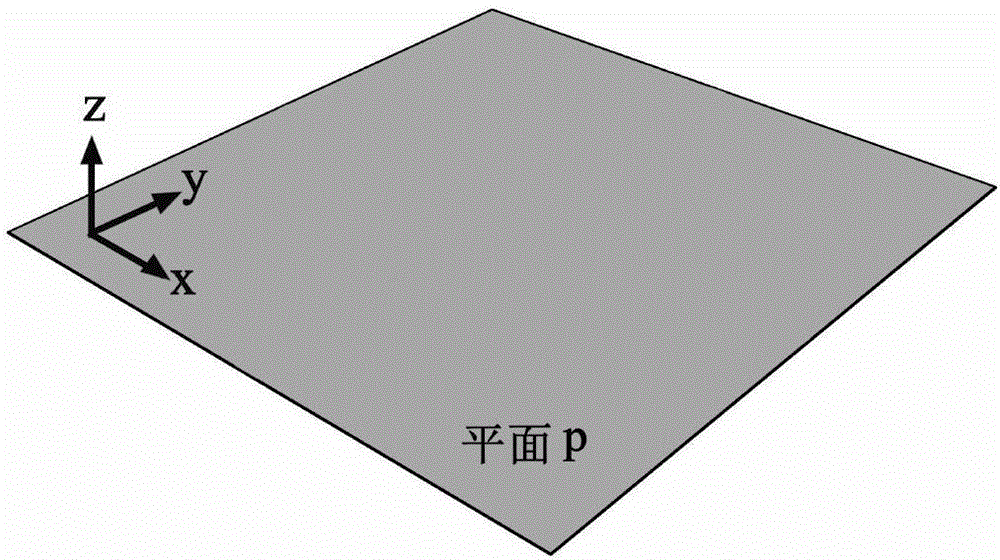

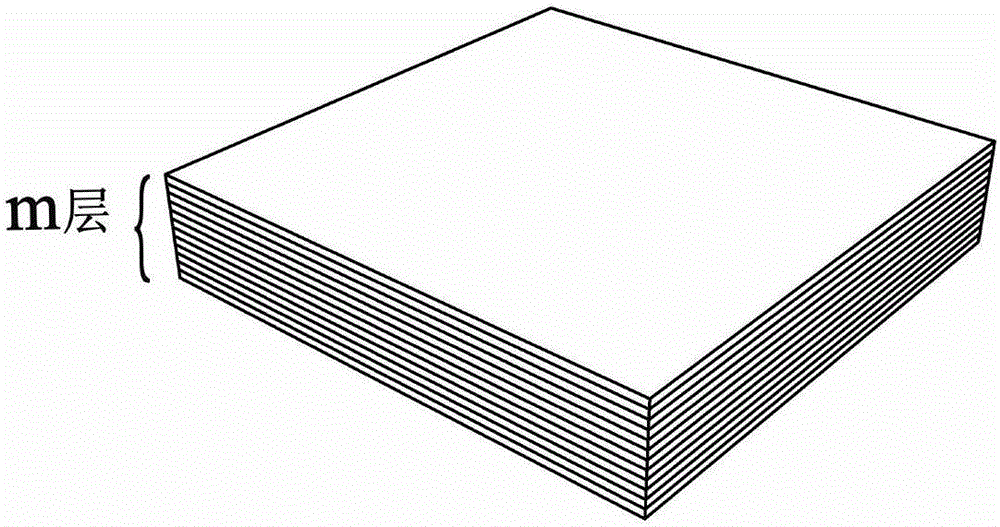

[0028] 1) Refer to figure 2 , image 3 , Figure 4 and Figure 5 , according to the shape of the stealth target, the unit layer grid division and the unit structure grid division are completed, and a three-dimensional space grid composed of several cube unit grids is obtained; the x band is selected as the stealth band, and the minimum wavelength λ in this band is 25mm, a is the side length of the cube unit grid, a satisfies a≤1 / 4λ, take a=5mm; m is the number of layers of the unit layer, m≥12, take m=12; select the aircraft horizontal wing surface 300mm×300mm The square plane area is the target object to be hidden. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com