Enforcedly spread type core molten debris catcher

A core melt and trap technology, which is applied in the direction of reactors, nuclear power generation, climate sustainability, etc., can solve the problem of full expansion of the melt without considering the means of forced spreading, so as to avoid the failure of the protective barrier and engineering flexibility The effect of improving and simplifying the post-accident handling work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

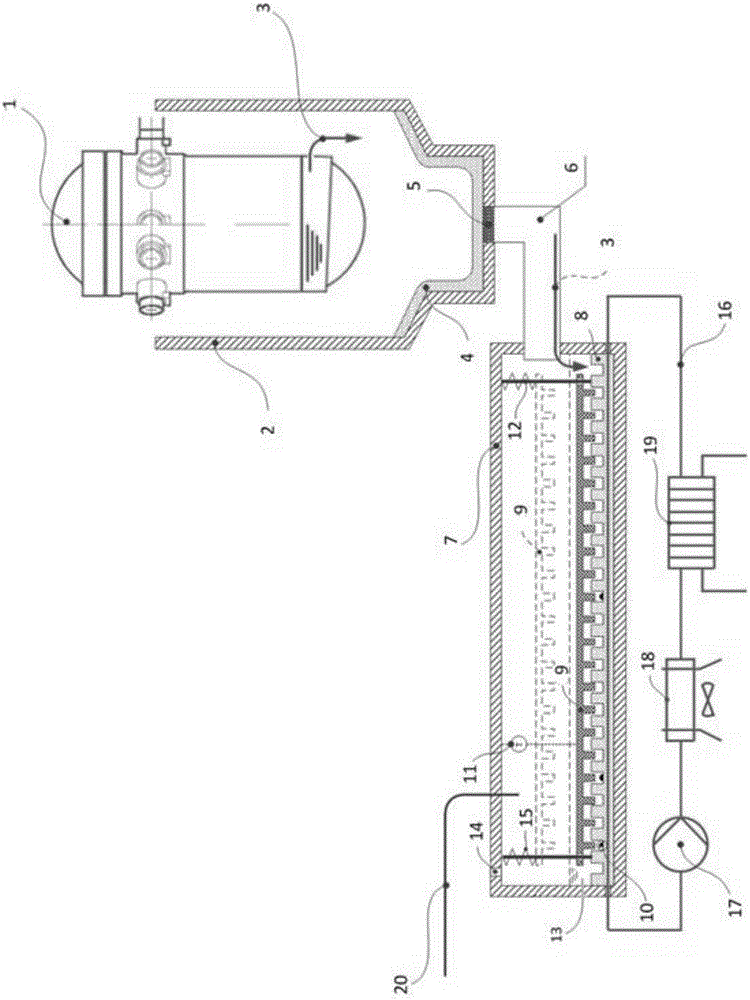

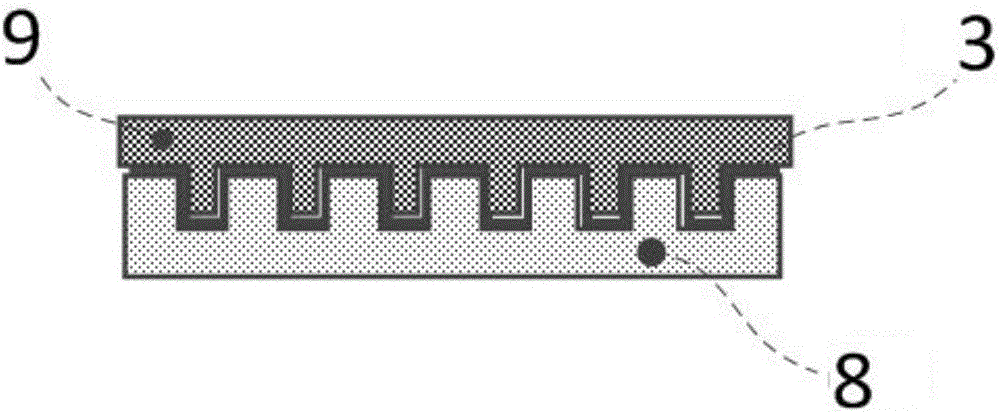

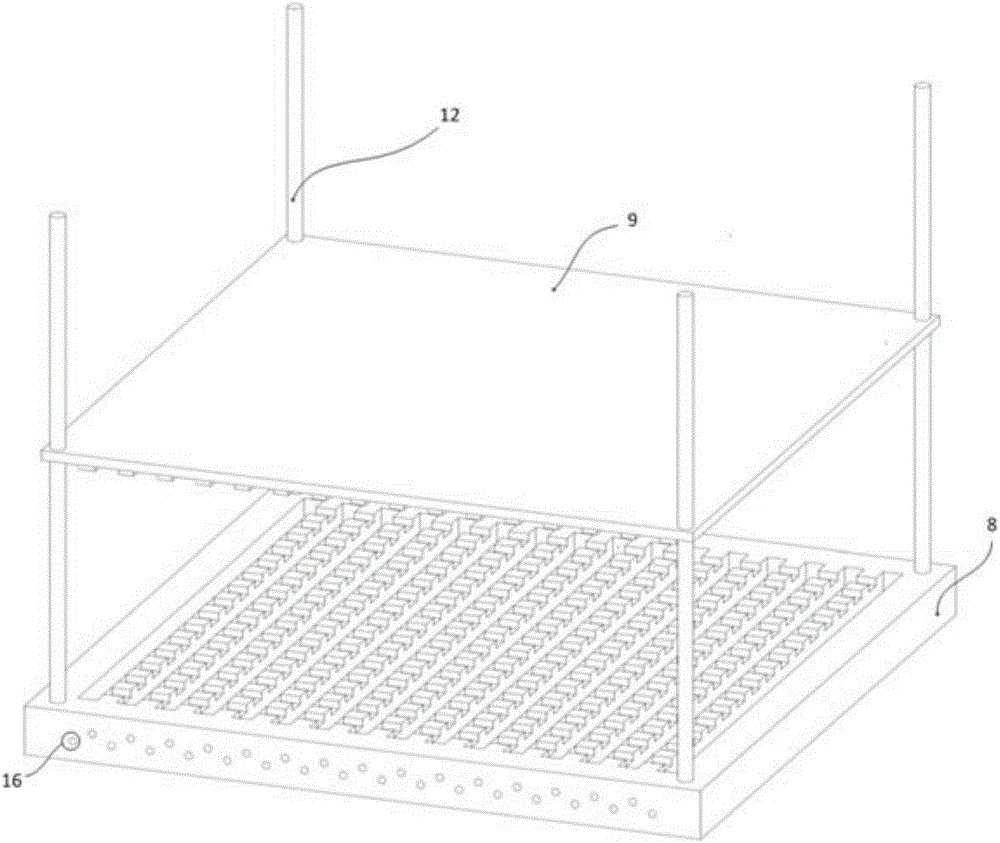

[0029] like figure 1 As shown, a core catcher for forced spreading of molten material provided by the present invention includes: a molten material expansion chamber 7 connected to the reactor pit 2 through a molten material transfer channel 6, wherein the inner bottom surface of the molten material expansion chamber 7 is set There is a catcher bottom plate 8 capable of carrying the melt conveyed by the melt transfer passage 6, a catcher cover plate 9 with a catcher cover plate exhaust hole 94 arranged above the catcher bottom plate 8, and the catcher Bottom plate 8, catcher cover plate 9 are connected by several cover plate falling directional supports 12, catcher cover plate 9 can cover on described catcher bottom plate 8 (catcher bottom plate 8, catcher cover plate 9 and the connection relationship of the falling directional support 12 of the cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com